Re-Track a 75M (9 Pieces) length of the iconic The Big One rollercoaster In Blackpool, with re-designed curve for better dynamics.

What were the challenges and what made the project successful?

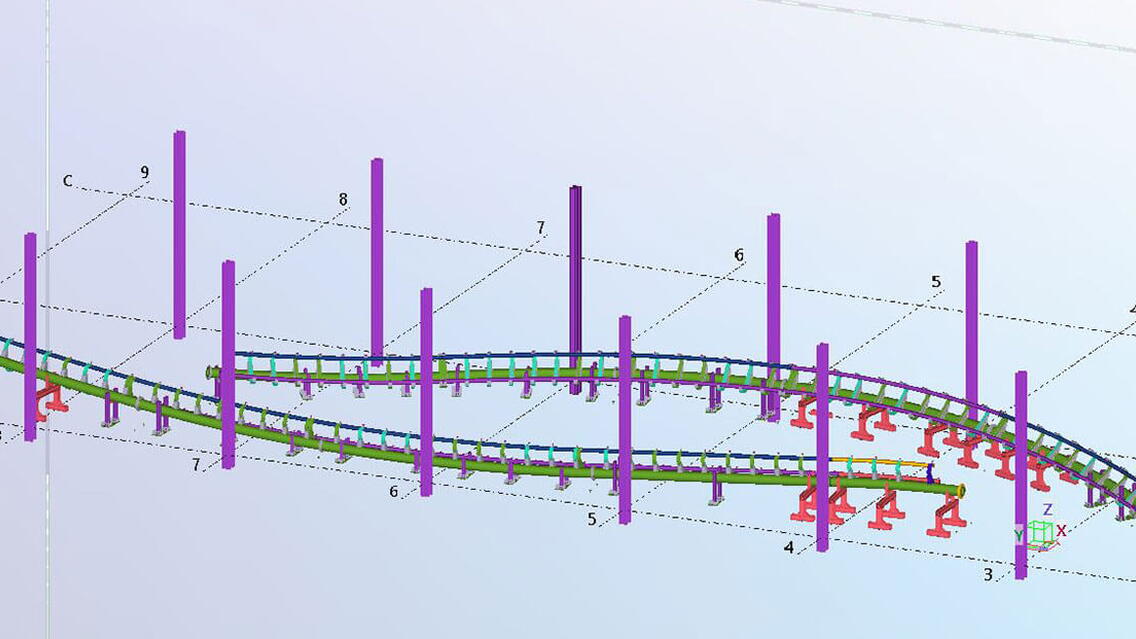

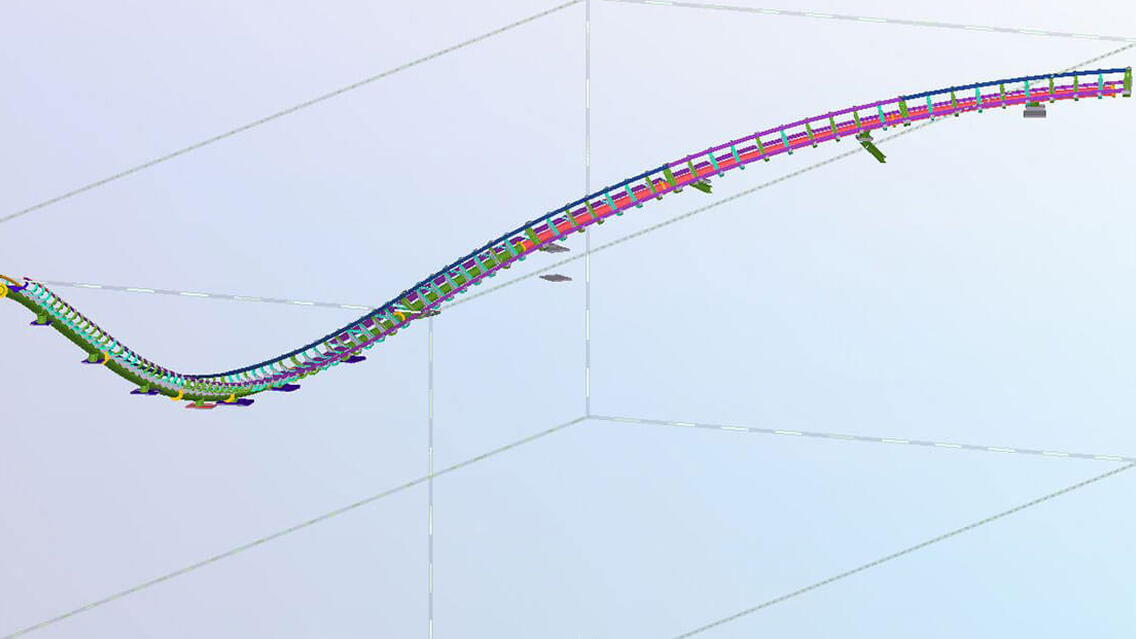

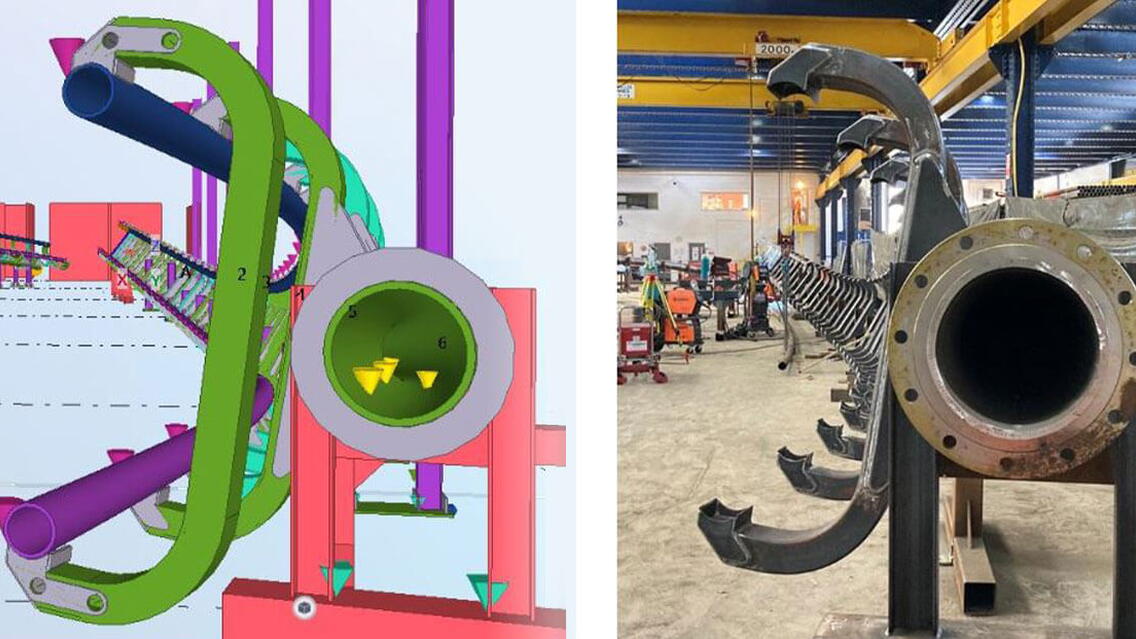

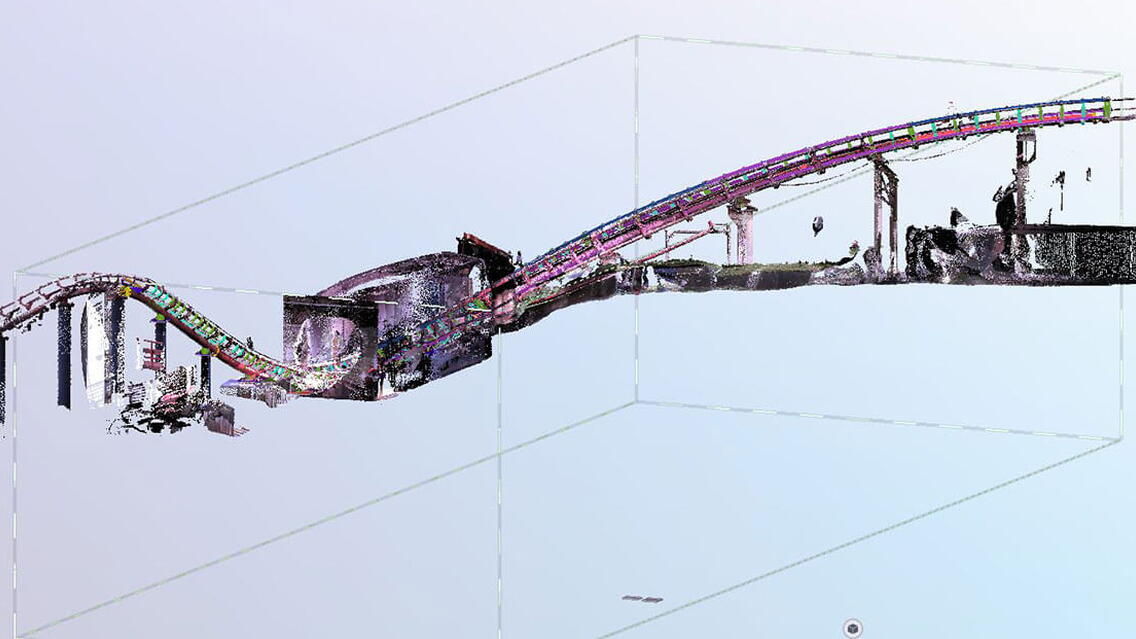

Challenges were complex geometry, using Point cloud to determine the geometry of existing track which was then exported to a dynamicist for improvements to the line of the track. Also, re- importing new line and modelling with the mindset of not using compound radii on any piece of rolled Tube, and minimizing butt welded joints to reduce costs required by x-ray ndt requirements.

Tekla Structures was the key to the success of this project and using its many tools such as:

- Point cloud import

- Layout manager

- Grasshopper link

Having the ability to coordinate site (point cloud) model, and backcheck using Total station to confirm geometry was essential. We were also able to add in the rides safety envelope through the tunnel to confirm the need to remove some of the façade. We were able to work closely with Blackpool Pleasure beach and flow information back and forth using IFC export, images ETC.

What are you most proud of about the project?

We are most proud of the exceptional fit up to the existing ride, which is not just a testament to the technology but also the work of the fabricators that adopted fabrication direct from the model using layout point export to total station, we only needed drawings to Identify layout point names. The Feedback from the Rollercoaster community is also extremely good and something to be proud of.

The project in numbers

- 70 construction circles

- 97 ties

- 75.5 M of rolled tubing