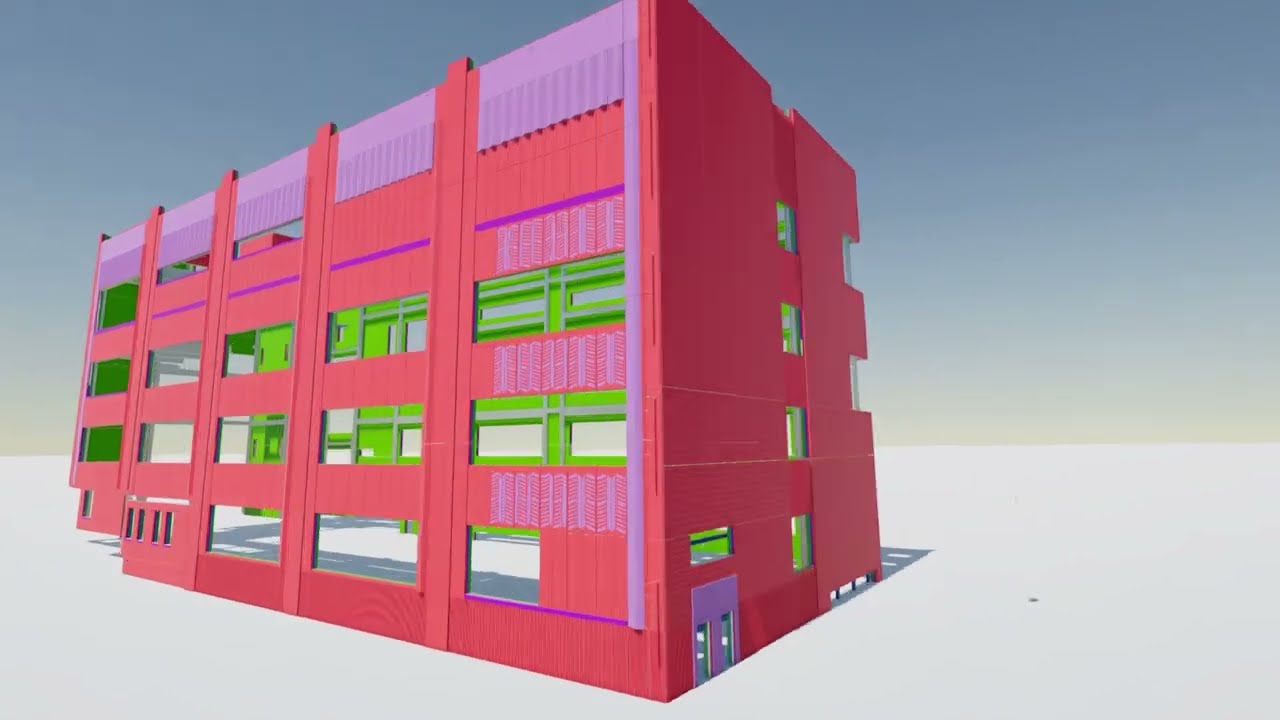

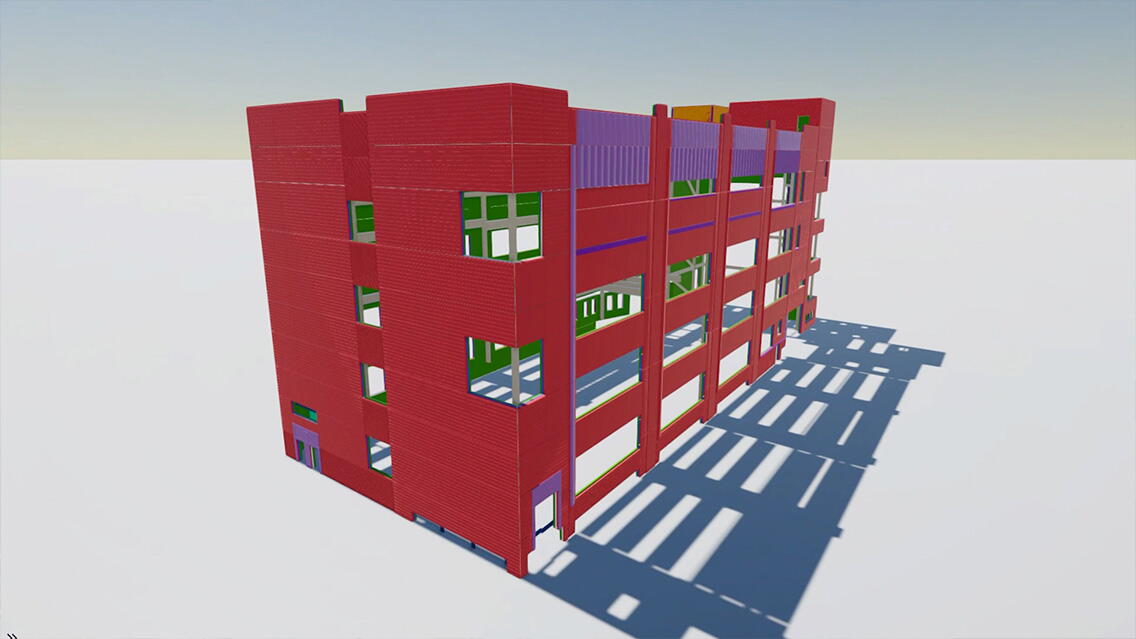

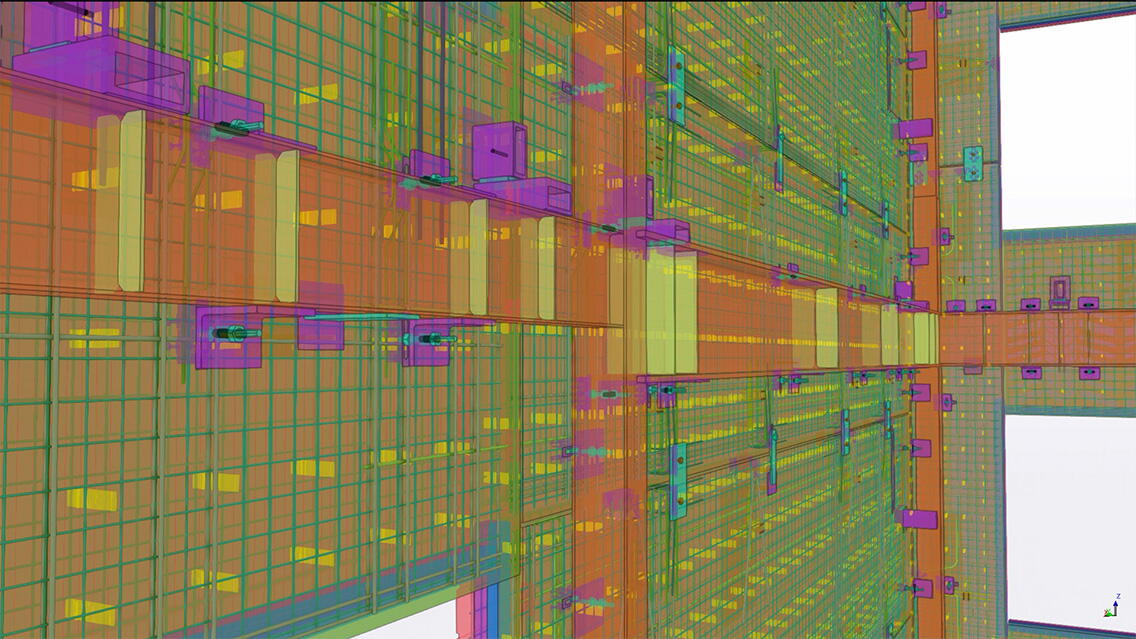

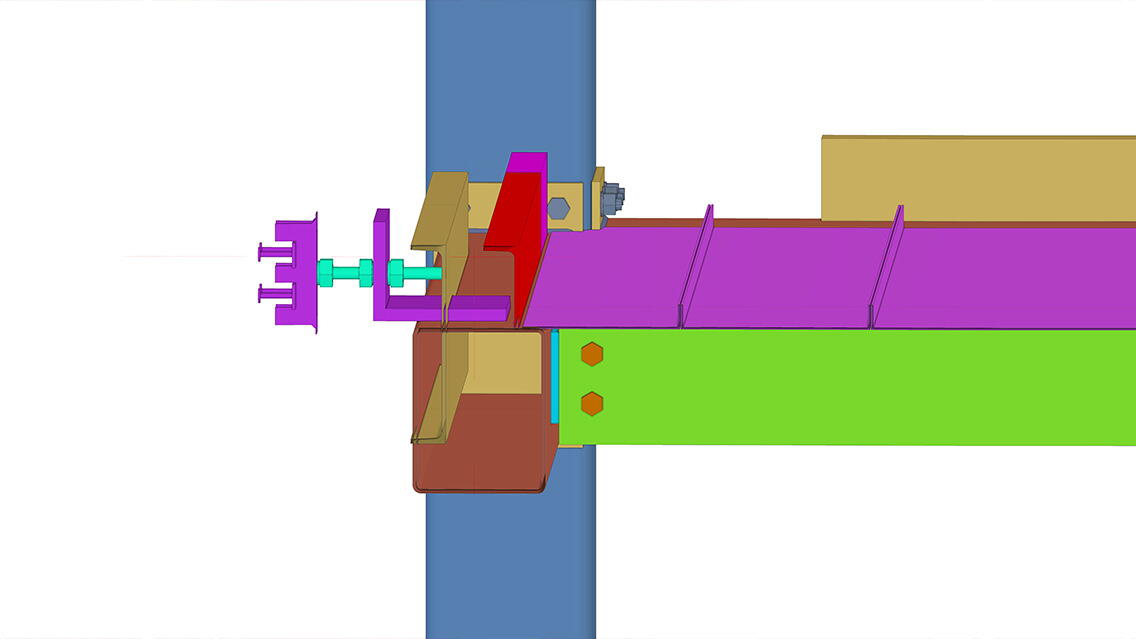

Habib & Associates, Inc.'s role in this project was to design and detail the insulated architectural precast cladding panels and their connections to the total structural system. Tekla 3D modeling and detailing software has been used to develop the 3D model, coordinate the connection to the steel members and is used to generate the 2D production shop drawings/ piece tickets. The Tekla 3D was a vital element in helping the general contractor, all trades and the design team to coordinate the precast system with the MEP requirements throughout the structure.

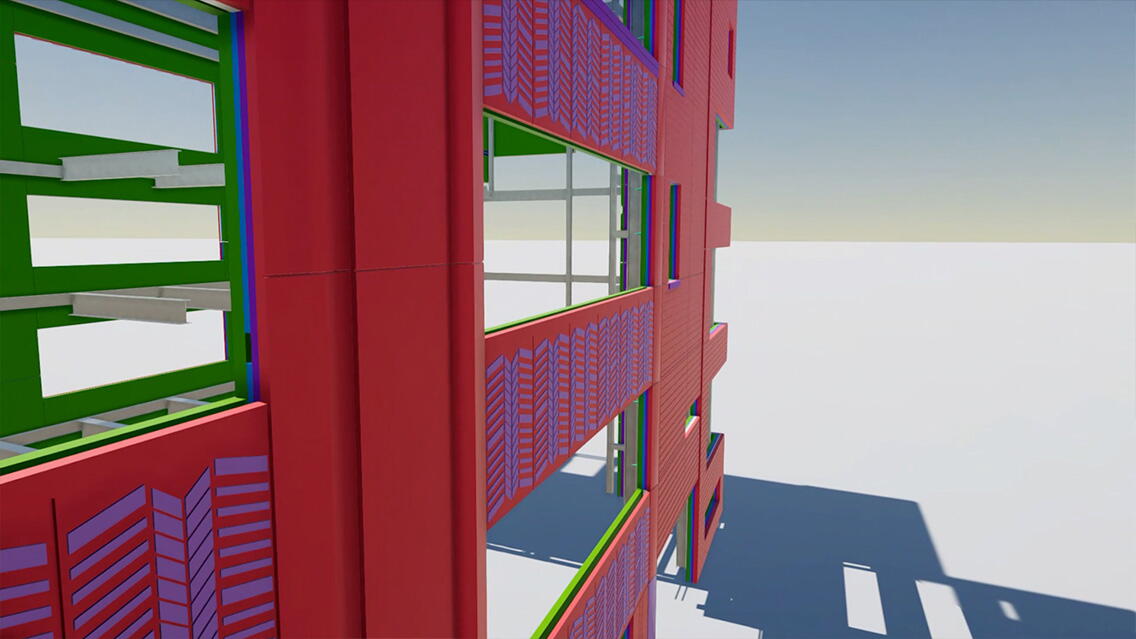

Precast cladding architecture demanded very specific details for this project, which consists of five elevated steel structures covered with precast panels of insulated architectural cladding. The precast panels are made using a colored architectural mix with an acid etch finish and laid in thin brick in parts of the elevations.

With the help of Tekla software, the precast panels and their connections were made without any errors from our end, allowing us to meet the contractor’s requirements to coordinate the precast cladding panels with the requirements of the different trades, particularly MEP ensuring that the precast components are connected to the steel structure without conflict, and coordinating with the MEP requirements.