THE PROJECT

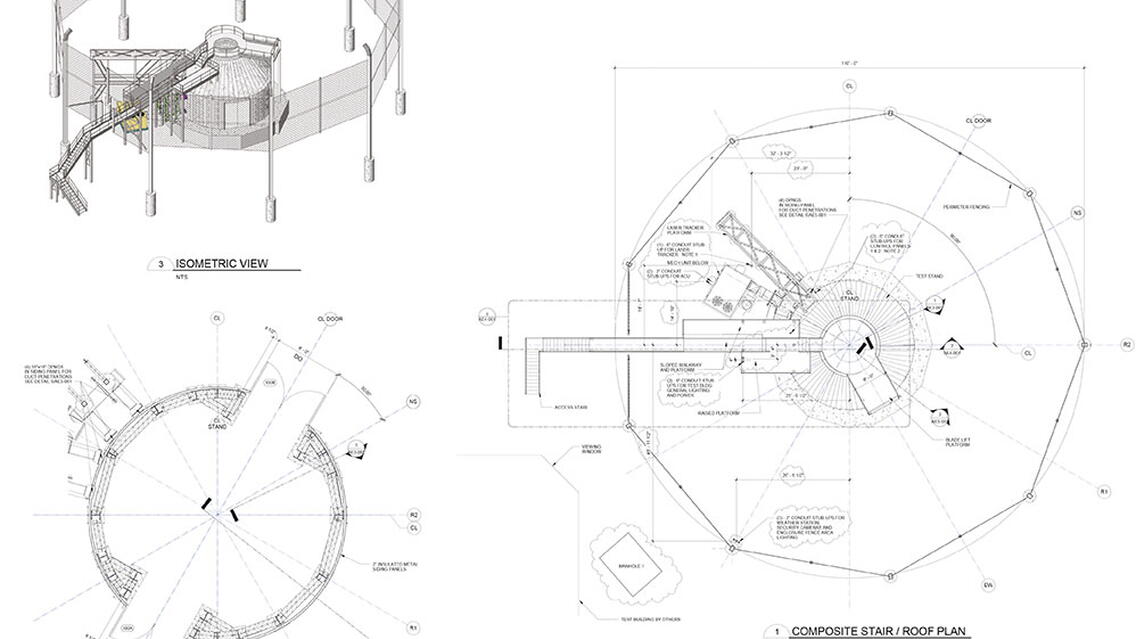

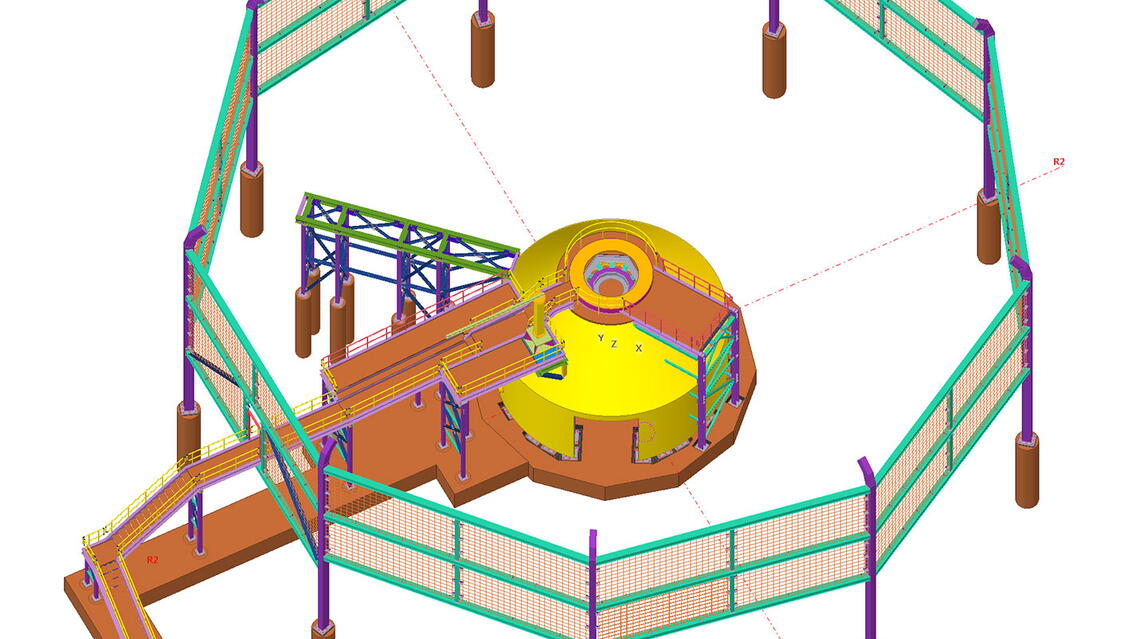

RedViking designed and built a unique whirl tower/blade balance stand to handle helicopter rotor blades from multiple OEMs. An enclosure was designed to improve and maintain testing capability in a desert environment.

Whirl Tower Increases Productivity and Efficiency

One of the world’s largest helicopter companies came to us with a challenge – design and build a new kind of blade balance stand. It needed to handle blades from multiple manufacturers, have greater availability in the challenging environment of its desert location, and improve overall productivity.

Custom Whirl Tower Enclosure for Desert Environment

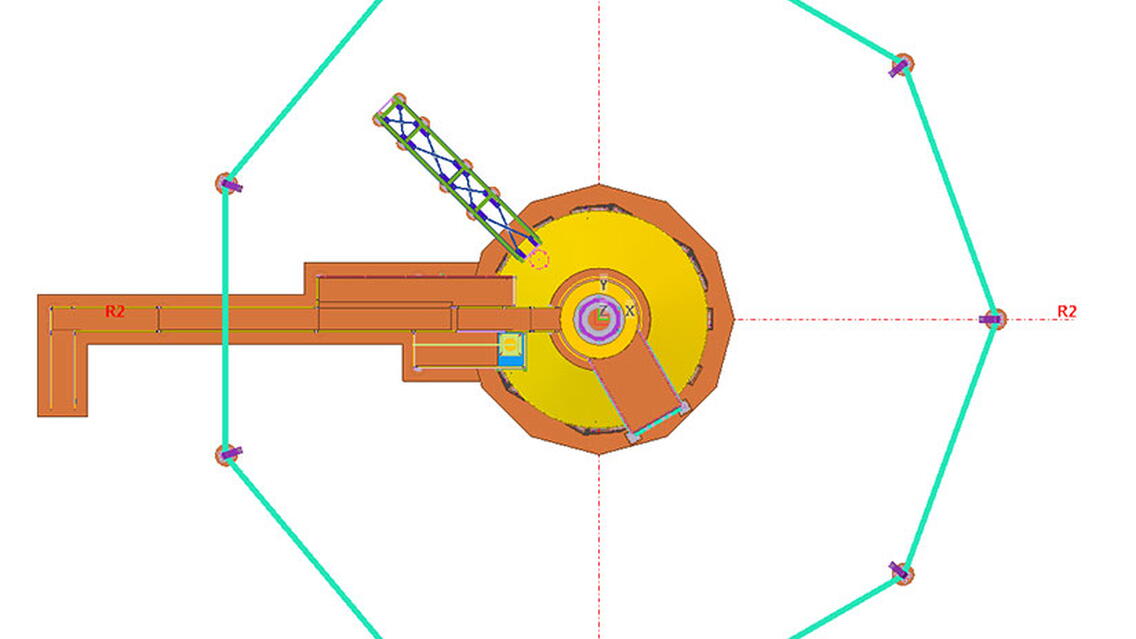

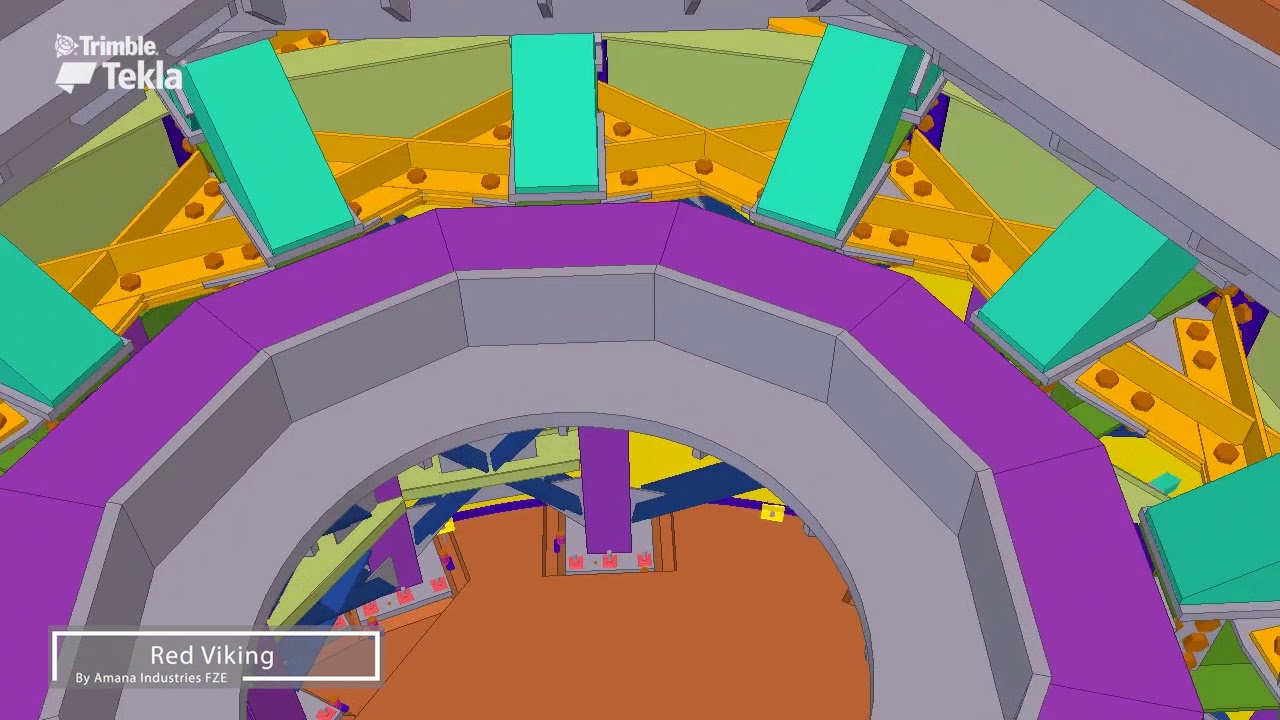

As specialists in flexible systems design, we developed an extensive range of rotary balancing capabilities to handle current and future requirements. The RedViking Blade Balance Stand is also designed to monitor operating conditions of the gearbox tower structure, which isolates the gearbox from potentially harmful loads to significantly improve test stand gearbox life. A weatherproof, air-conditioned enclosure allows the whirl tower to operate in difficult testing environments under which most systems would not function.

Dual Helicopter Blade Lift Design Improves Productivity

The stand includes a dual blade lift device, allowing a blade to be unloaded and a new blade loaded in a single operation, reducing changeover time and improving productivity. The stand includes a Rotor Head specifically designed for dynamic blade balancing.

RedViking software is utilized to incorporate blade control, speed and blade measurements into one comprehensive package, greatly reducing operator training requirements and improving accuracy.

Torque Measurement and Blade History Tracking

An optional RedViking Whirl Tower component, Error Proofing, can be provided through an instrumented torque gun in order to provide reliable, historical data for bolt torques. Together with our fully integrated control system, this provides the ability for advanced data analysis and tracking.

The RedViking Blade Balance Stand saves time and money, improves productivity and provides better data analysis than has previously been possible.

SUCCESS FACTOR

The team achieved delivery schedule at right time.

WHY TEKLA

BIM management with Tekla prooved to be extremely useful to get clarifications from the client's end, allowing Amana and the team to visualize easily. Tekla software boosted the projects efficiency, accuracy & time management.

ABOUT AMANA INDUSTRIES

Amana Industries has the capabilities to provide complex steel solutions to its clients.

Amana Industries has a full-fledged structural engineering team capable of providing efficient and cost-effective solutions and designs for such projects as:

- Steel buildings

- Pressure vessels

- Pipe racks

- Petrol and water tanks

- Bollards

- Concrete Mixtures

- Platforms

- Mezzanines

- Pipe fabrication

- Erection of rotary/static equipment

- Steelworks for petrochemical plants

- Steelworks for refineries

- Architectural steel structures for high rises