Eversendai Engineering L.L.C, UAE was awarded 1,000 M Tons of Steel works for SAMBA HQ Roof Feature Project in Riyadh. The scope of Eversendai was to provide Connection Design, Shop Drawings, BIM Implimentation & Coordination, Erection Engineering Study & Stage Analysis, Workshop Fabrication Drawings, Supply, Fabrication, Painting, Fire Proofing, Composite Floor Decking, and Erection of Structural Steel Works. All the above scope of works was completely taken care in-house and successfully completed in line with project schedule.

The Project Client is Samaba Financial Group, The Architect is Fosters + Partners and Structural Engineer is Buro Happold and The Main Contractor is Elseif Engineering Contacting CO.

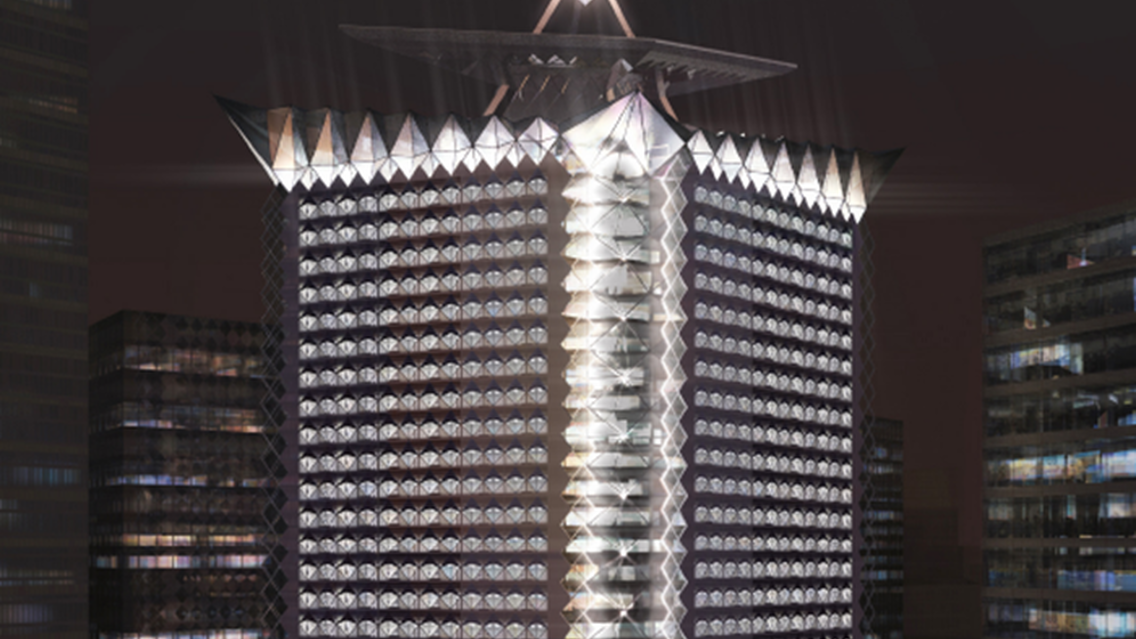

SAMBA HQ tower is located at Riyadh, Saudi Arabia (KSA). The height of the Samba HQ tower is about 230 m having 3 basements + 42 floors + Roof features.

The Roof Steelwork on SAMBA HQ Tower starts from Level 42 which consists of Tower Roof Feature, Collector Platform and Spire tower.

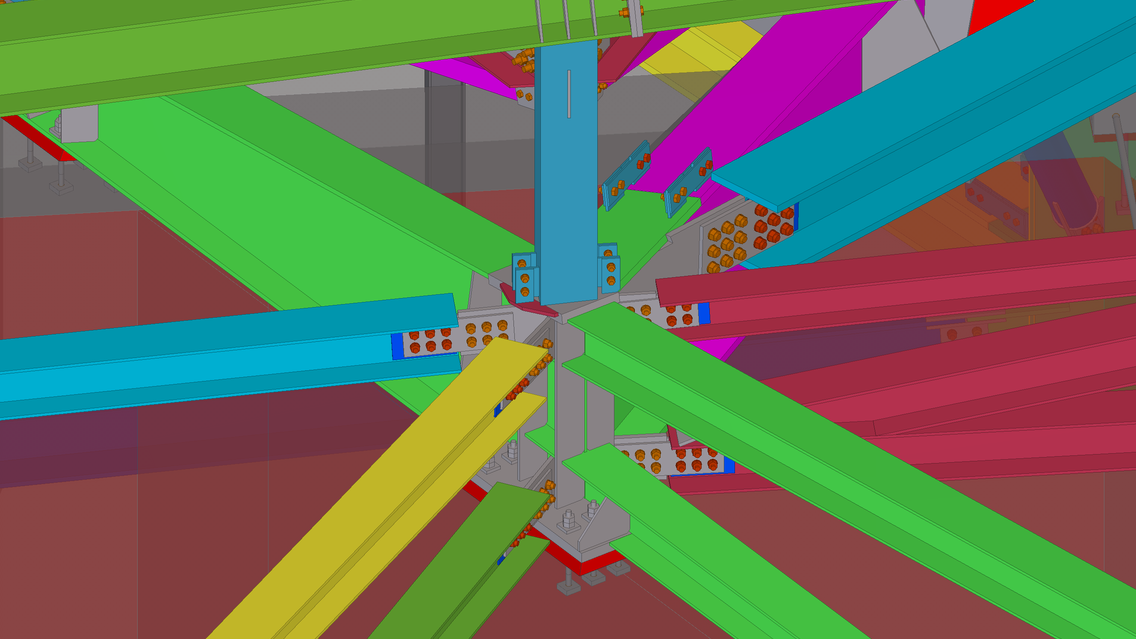

Tower Roof consists of Trusses of height 3.0m at 6.0m spacing spanning in 3 directions on plan. The trusses which were supported over RC column, Y shaped column & core wall are considered as primary trusses. The trusses which were spanning between primary trusses are considered as secondary trusses. Tower roof involves complex connections where multiple members join at a single node.

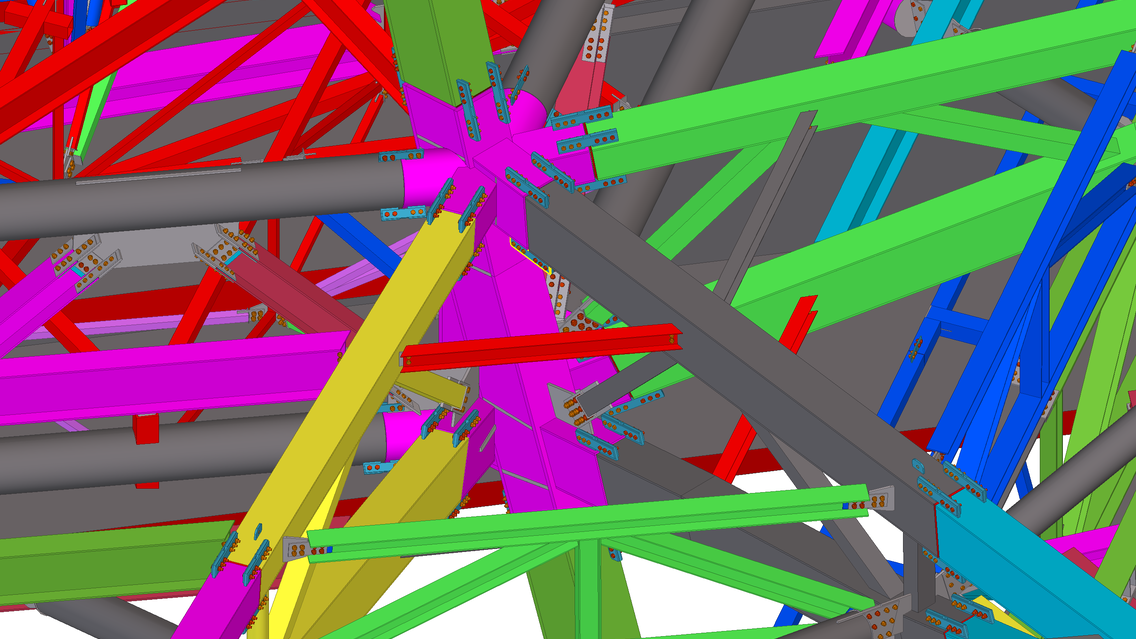

Collector platform consists of 14.0m cantilever trusses cantilevering from spire legs with beams spanning between the cantilever trusses. Compression trusses were provided between the spire legs to resist the loads from the cantilever trusses. Stability is provided by cantilever action of trusses & plan bracings. Collector platform also involves complex connections where multi-members join at a single node.

Spire is about 74m high formed by 4 legs tapered to a Top point. Spire is supported by tower roof trusses. Plate fabricated ring beam tied at regular intervals with rigid connections to provide stability for portal action & also provides torsional rigidity. The spire legs are of plate fabricated tapered rectangular box to reduce slenderness and less tendency to dynamic response. The connections in spire were done by considering fatigue requirements.