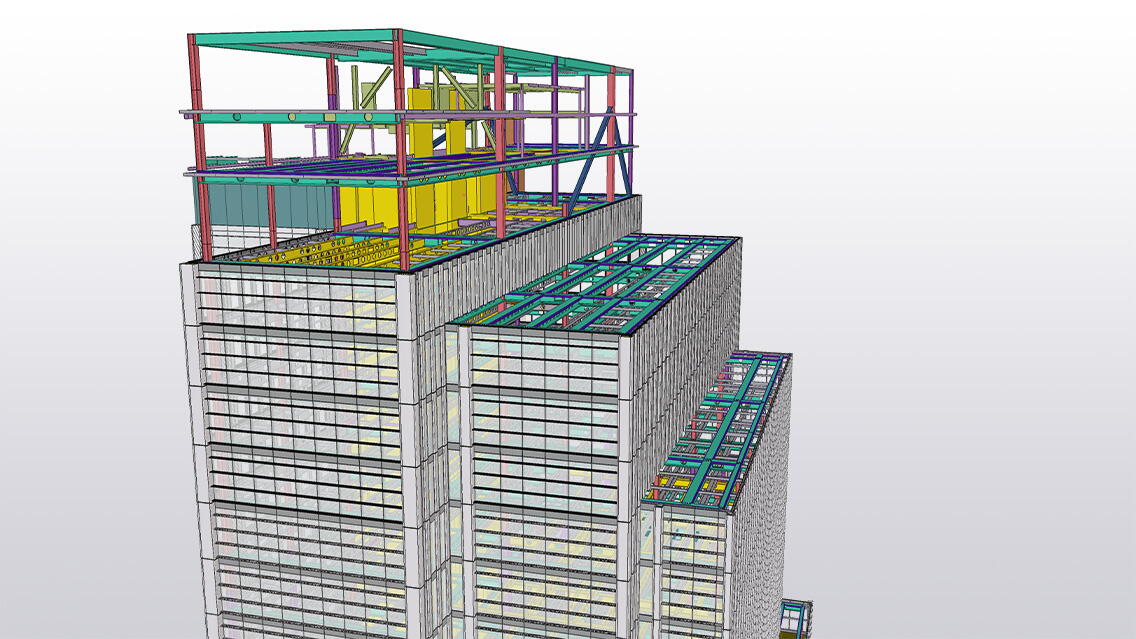

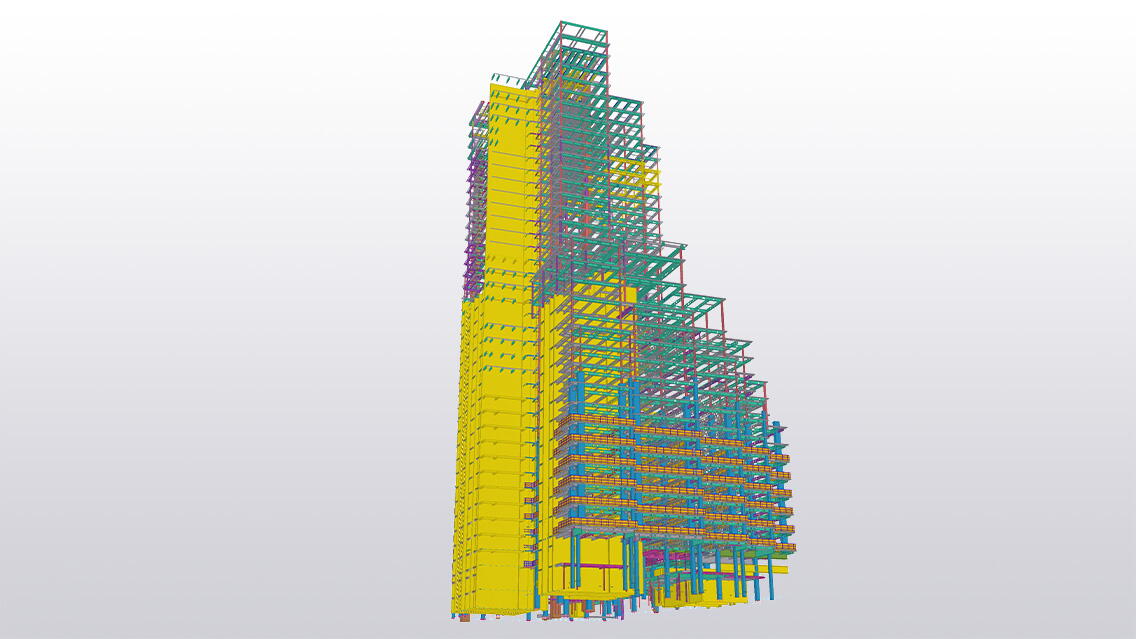

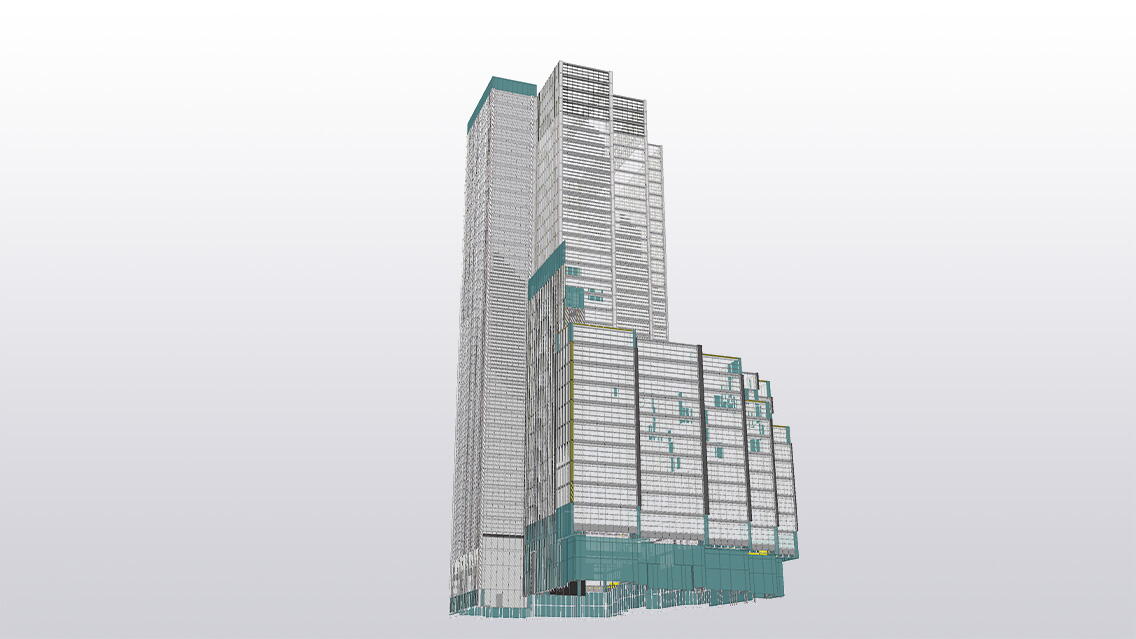

40 Leadenhall Street is one of the largest buildings to have ever received planning permission in the City of London. The scheme’s stepped design cascades down towards the River Thames and has been described as resembling a Gotham City skyscraper, where Batman calls home. The colossal structure has already been earmarked for new offices, with retail units at street level, and is described as a ‘destination office’ that can provide a number of amenities to entice workers back into the office post-COVID.

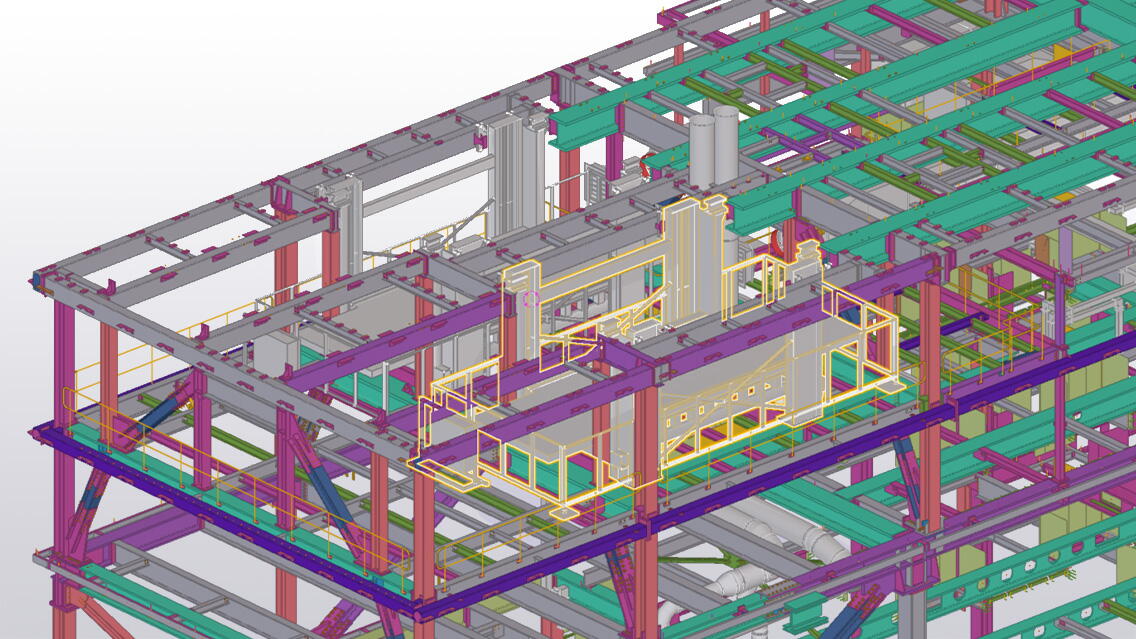

The sheer scale of this iconic project presented unique challenges, not least that the steel frame superstructure rises to 34 storey height. As such, William Hare had the mammoth task of undertaking the structural connection design, steel fabrication, and steel installation.

Challenges and achievements

Due to the complex nature of the ‘Gotham City’ project at 40 Leadenhall Street, there were a number of complex lower floor connections that had to be factored into the fabrication and installation processes. In addition to this, a number of both architecturally and structurally complex elements were designed within the structure, including (among many other elements) a spiral staircase.

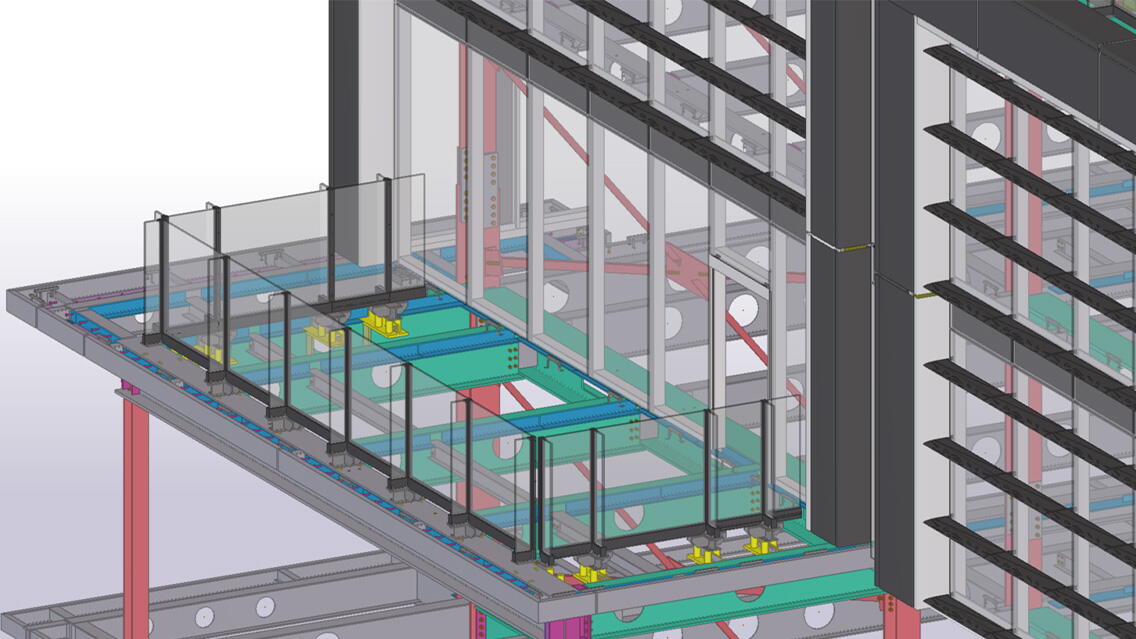

Issues have been rare on the 'Gotham City' skyscraper and as of April 2024 the construction has so far kept to schedule. This can be attributed to the interaction of various 3D platforms throughout the construction process, making clash detection and problem solving simple and tracked with ease. An example includes Hare's collaboration with Focchi, principal contractors for the glazing of the colossal structure, where close interaction overcame connection problems with ease.

Using Tekla software

- Almost all of William Hare’s production plant relies on model data (primarily NC data) for cutting and drilling of both profiles and plates. Robotic fabrication undertakes automated assembly and welding that uses XML files extracted from the 3D model.

- Site progress was highlighted via colour coding and metadata within Tekla Structures.

- IFC was the standard format used to import to and from the 3D Tekla model.

- Custom components were used for both standard parts like edge protection, and more complex components, including cellholes and multiple call off pieces.

- Bespoke UDA data was used to allow advance of order steel, intumescent paint data, phasing information, and lotting information.

- Tekla Structures was integral for visualisation and communication between stakeholders, including for: client workshops, internal meetings for fabrication, creation of build sequences of complex nodes, ability to obtain dimensions and weights with simplicity. William Hare also documented ‘almost real-time progress on site’ with interaction of internal applications.

What does William Hare Limited say about the project?

“‘Project Gotham City’ is a catchy nickname for the 40 Leadenhall Street project. Trimble software facilitated William Hare’s collaboration with Focchi, MACE, WSP, and MAKE. The steelwork model was given priority for use by other contractors due to the ability of the detailing team to advance the model to be geometrically the same as per the engineer’s model, and sometimes even more advanced due to variations and changes to the geometry via workshops.”

- Sian Gilbertson, Bid Manager at William Hare Limited