The German office SEELE designed the structure, and Andrade Rezende Engenharia prepared the details for manufacturing and assembly.

About the project

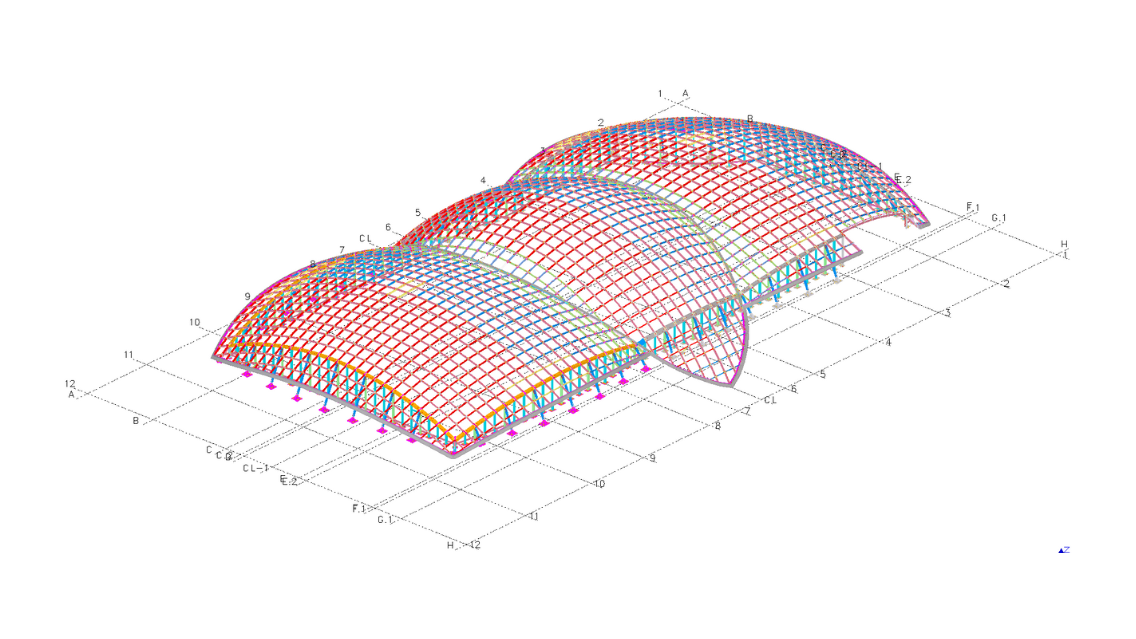

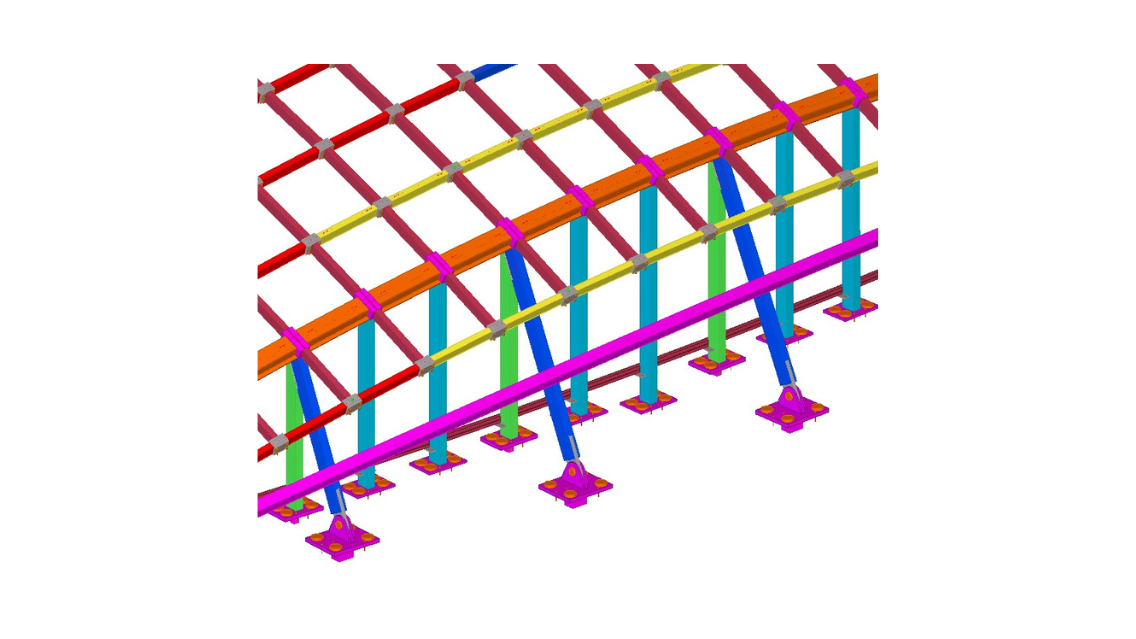

The structure has a metallic roof composed of three domes featuring distinct and non-symmetrical curvatures designed in rectangular tubular profiles. It also features special glass produced in Italy which gives the building an aesthetic appeal.

Andrade Rezende participated as a contractor in preparing detailing projects for manufacturing and assembly, and Brafer participated as a contractor in manufacturing and assembly.

Challenges and success factors

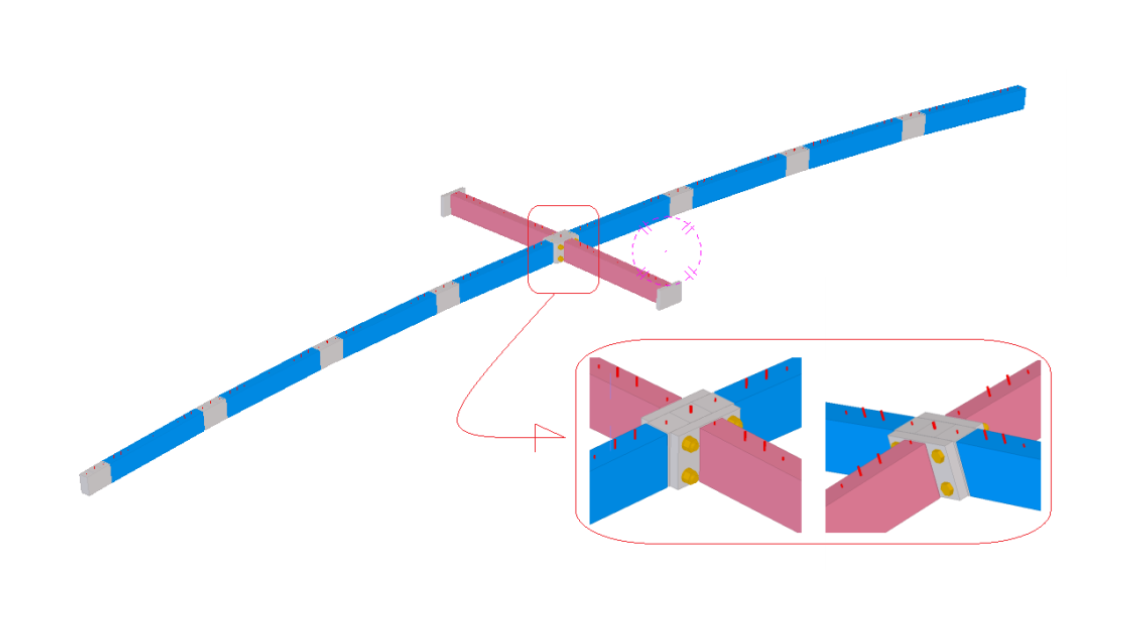

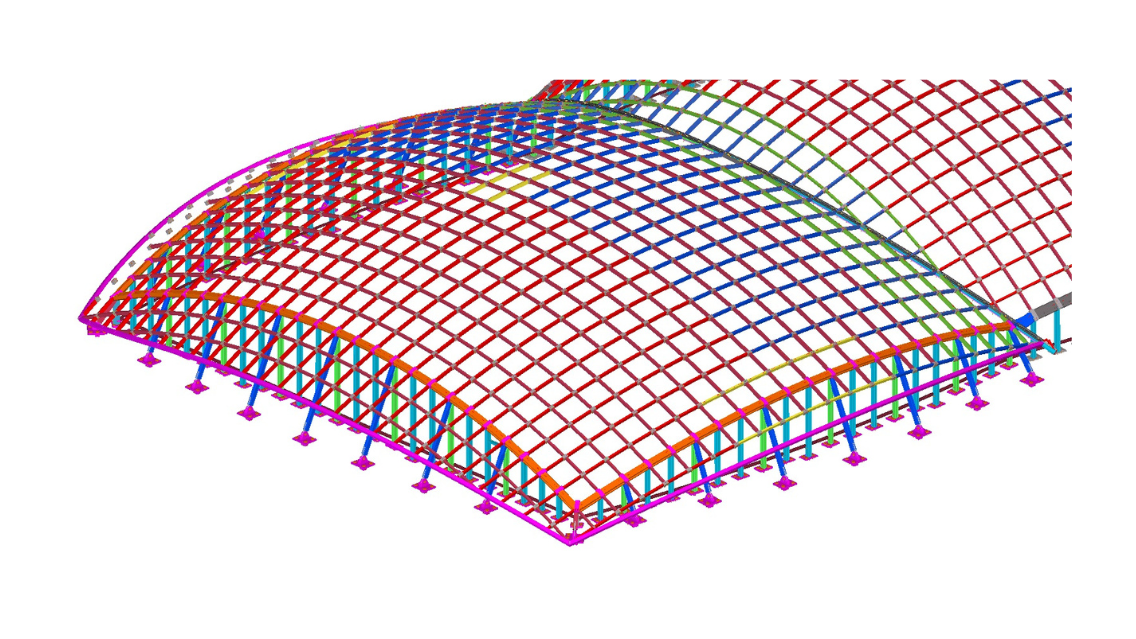

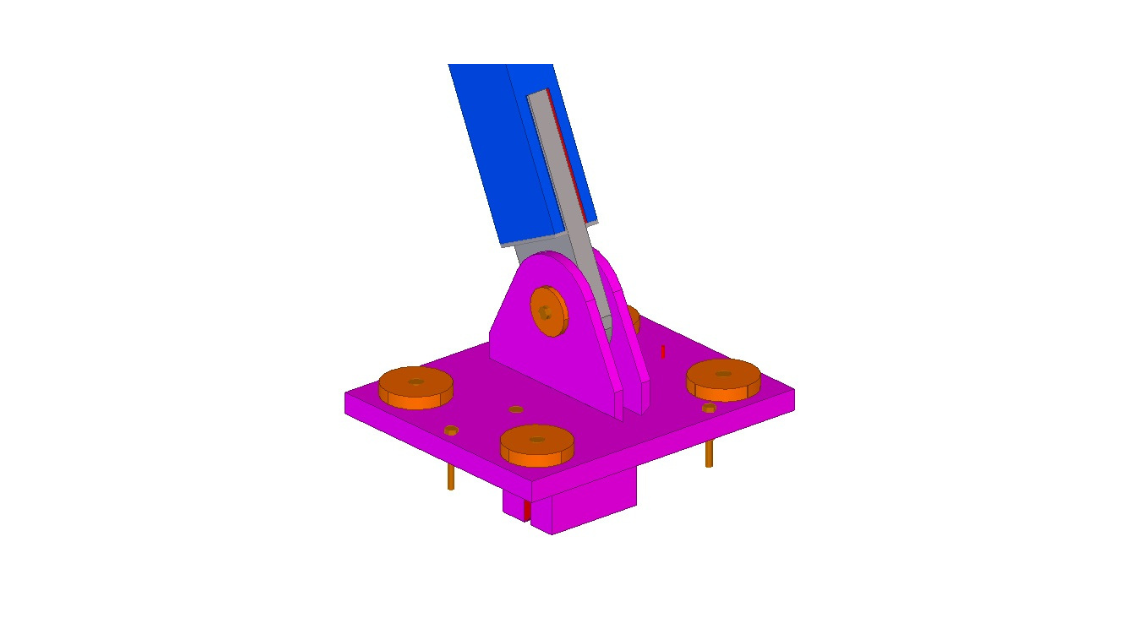

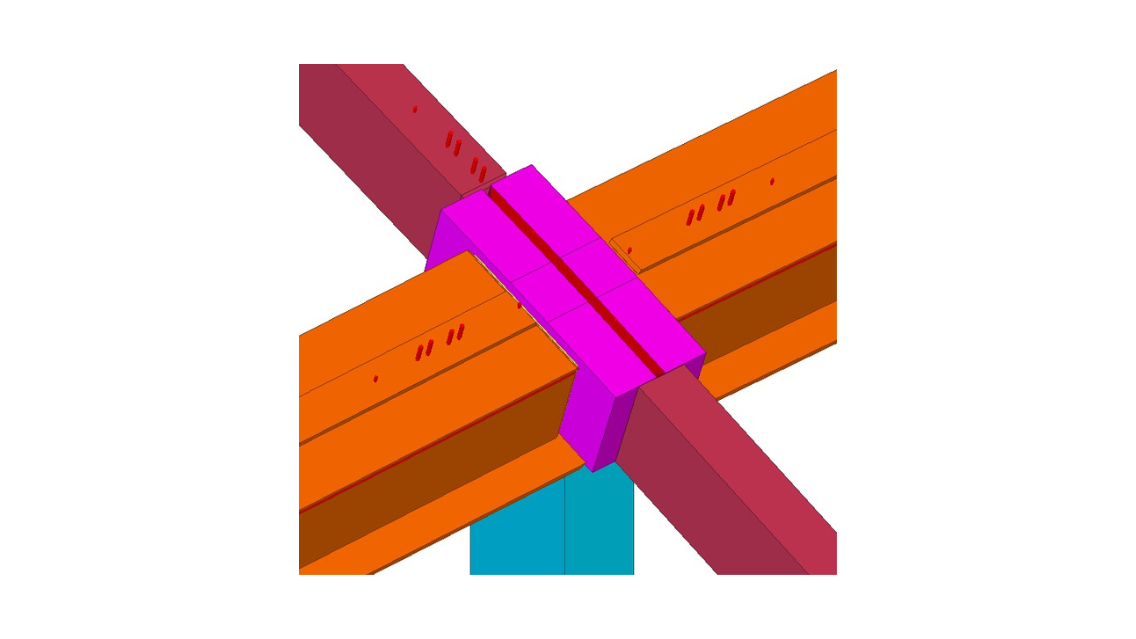

The biggest challenge of this project was modeling the anti-arrow coverage in non-symmetrical arcs, with different curvatures in all directions and angular precision in the order of seconds so that, after assembly and loading, they reached the correct design position. Typical connections for secondary beams in the sector called grid beams were designed as flanges connected to a solid block 100 mm thick, which was already welded at the factory to the main beam.

The main connections of the grid beam, header beam, edge beam, and gutter sheet sectors at the interfaces with columns were designed as field penetration welds, which required the team to pay a lot of attention when creating all the necessary chamfers.

Due to the different geometry of the roof structure, with asymmetrical curves in all directions, the tools provided by Tekla Structures were fundamental in designing the roof against sagging with the precision required by the client. Furthermore, the BIM technology resource that the software has enabled meant we could successfully work on achieving full compatibility with the IFC reference files sent by the contractor.