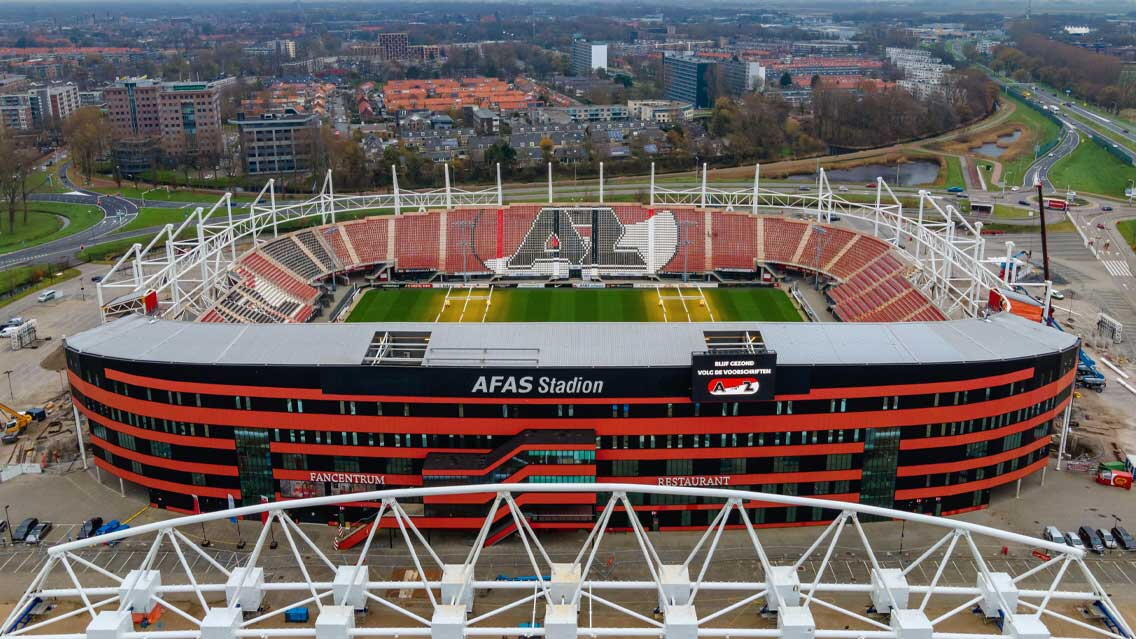

In August 2019, football fans were startled by fierce images from Alkmaar when part of the roof above the Molenaar stand collapsed during a storm. Fortunately, no games were going on at the time, and no one was injured, but the damage was enormous. A combination of design faults in the structural connections welded joints that were too thin, and previously incurred storm damage, were found to be the underlying cause of the collapse.

At the end of 2019, ASK Romein was selected to work out the architectural and structural design into an implementation design, together with BAM Bouw en Techniek, after which the turnkey agreement for the construction of the new roof was concluded in May 2020. ASK Romein is responsible for engineering, production, conservation, and steel construction within this collaboration. Safety and quality are, of course, paramount.

Design

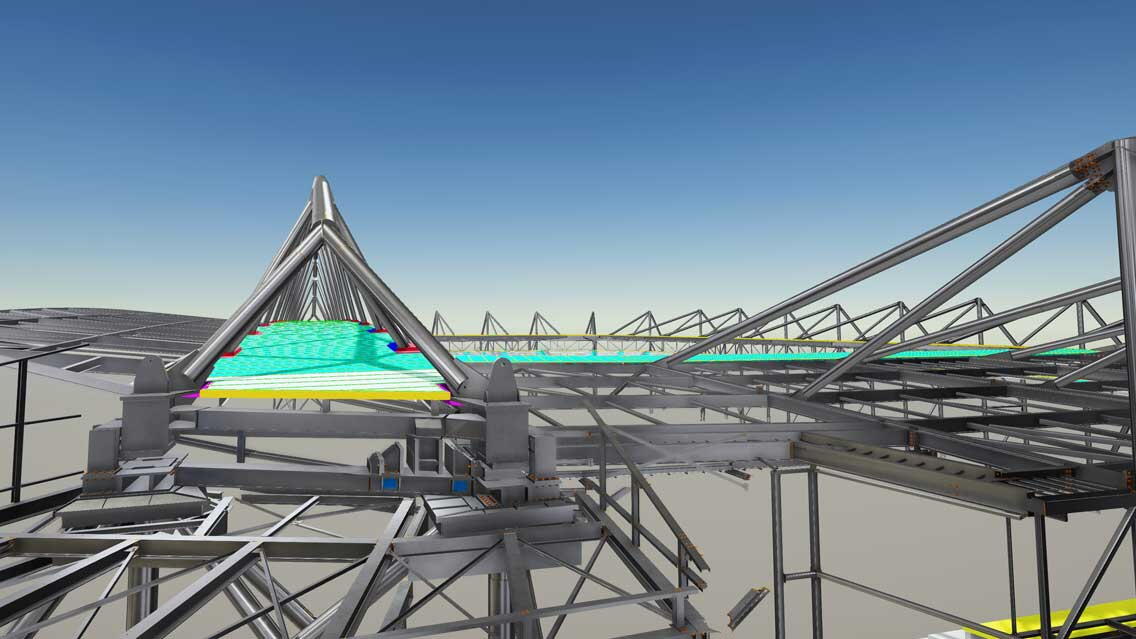

The new design of the new roof was made by the architectural firm ZJA. A completely new roof is being built around the stadium, which is separate from the existing building. The roof above the main stand is supported by an enormous truss (mega-truss), with a weight of 600 tons and a span of 170 meters at a height of 17 meters. This truss protrudes through the corners of the main stand on two sides. The construction of the truss takes place next to the stadium. The truss will be lifted over the stadium with two enormous cranes and placed on four advanced support points, which must follow all thermal expansions and movements of the truss.

ZJA’s design for the renovation of the roof makes optimal use of the space around the stadium, resulting in a roof supported by a series of crane-like structures outside the stadium. The new roof is straight and protrudes 30m into the stadium, providing more protection against rain and wind than the old roof.

Engineering

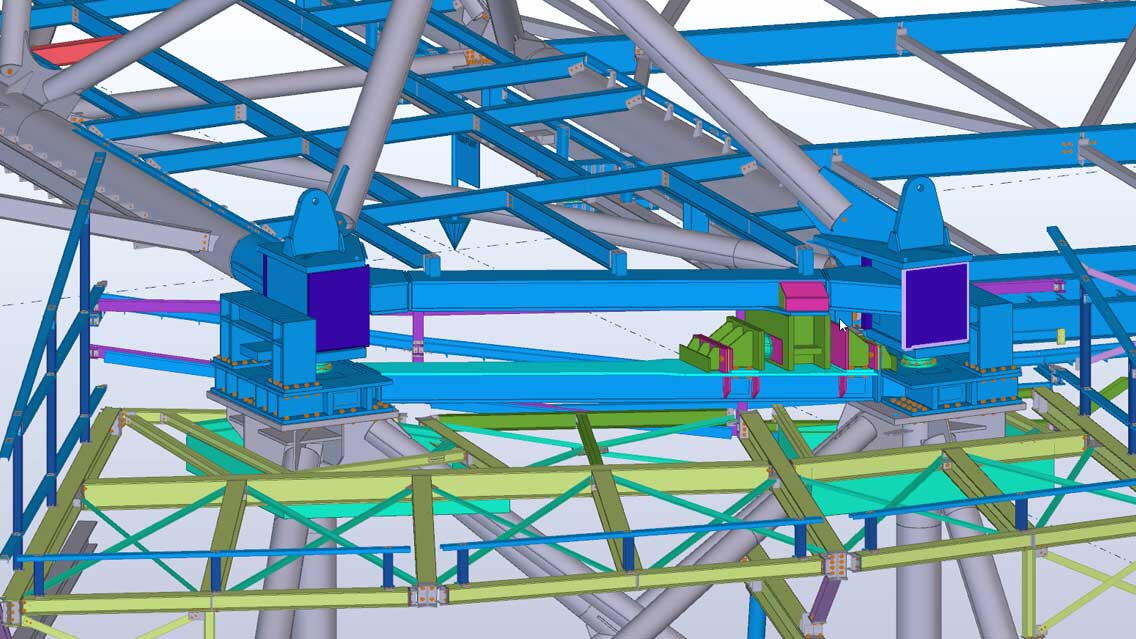

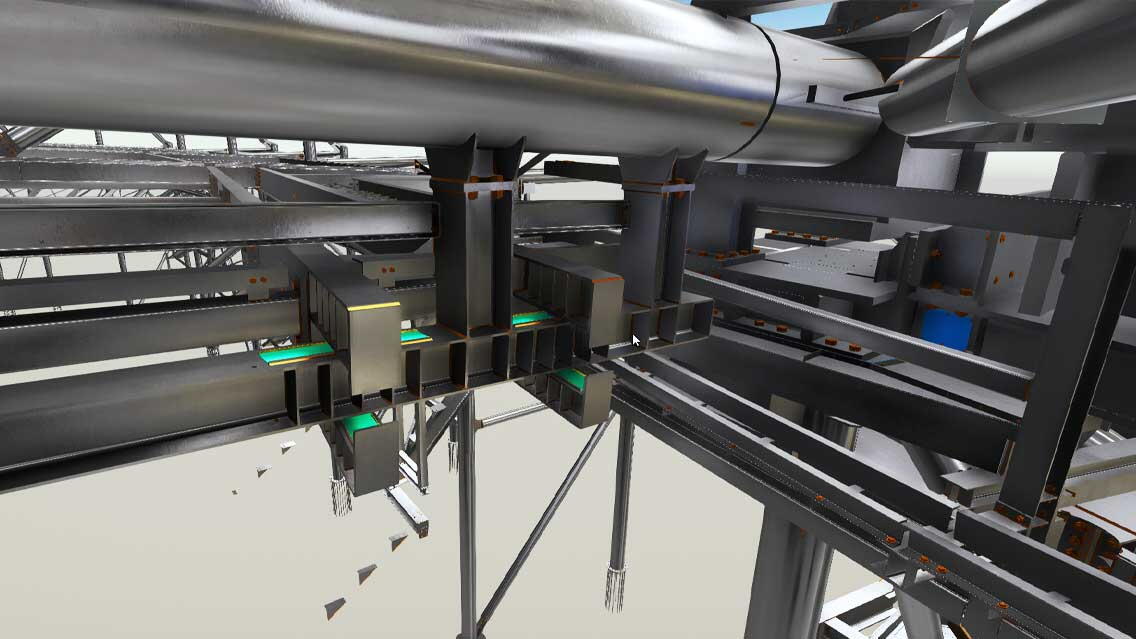

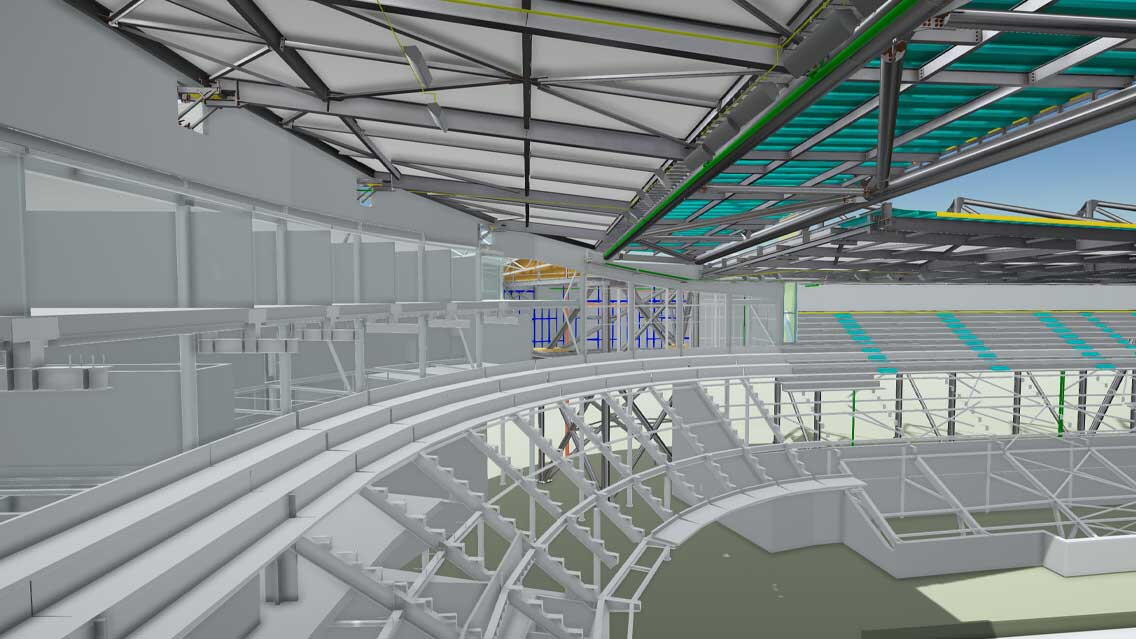

During the entire engineering process, optimal use has been made of BIM. Good preparation at the office, in combination with clear communication between all project stakeholders and seamless exchange between the different software packages, resulted in a visually and technically impressive project.

Because there are many interfaces between the existing and new buildings, point clouds (3D scans) were used during the engineering and assembly process. These point clouds were converted to IFC plans. These IFC models were used as reference models in Tekla Structures which provided a lot of insight into every phase of the project.

To the construction site

To ensure that the construction ran smoothly, the assembly manager and the foremen were equipped with a tablet/laptop on which they could consult the 3D model and the accompanying drawings at any time in Trimble Connect, which offered more advantages than traditional drawings. For example, it immediately gives the mechanics more insight into the connections, bolt diameters, etc. Opening linked installation drawings are also easy, and the feedback to engineering can be shared in a few clicks in case of problems on the construction site. What’s more, everyone works with the latest information and from the same documents to minimize the chance of miscommunication or working with incorrect information.