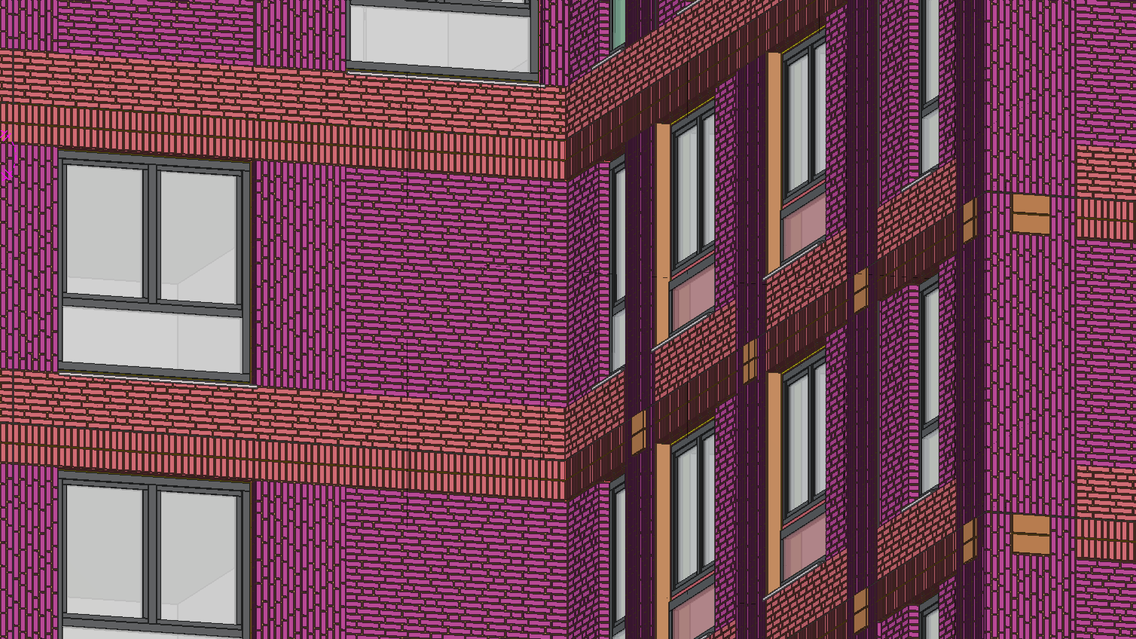

In Helmond, an apartment complex with 73 care units is currently being built for the care of (single) adults without children. The existing building has been demolished, and a completely new complex is being built on the same site. VKP has taken care of the wall-filling elements which come directly from our own factory. These elements are completely finished with mineral strips and window frames, including glass, so that scaffolding-free construction is possible. We worked with different masonry dressings and strip colors and also applied strips with a degree angle of 95 degrees for drainage.

The HSB was modeled using Tekla Structures according to all BIM aspects, such as the BIM base ILS, NL-SFB coding, building layer naming, IFC classification, IsExtenal, and Loadbaring. In addition, we also added the stone strip and joint colors in the model so that we no longer need to generate material states in Tekla. Certain settings even allow our job planners to generate material states in PDF or Excel format from Trimble Connect. We also incorporate element numbers, detail numbers, material data and, if necessary, the assembly schedule, among other things, into our model so that other colleagues can read various data from our model using preset filters in Trimble Connect. Also, all fasteners for the shell construction are drawn out such as corner and strip anchors. We are currently making various settings so that the article numbers can also be extracted from the IFC model and, if necessary, order lists can be generated. We are also experimenting with linking a hyperlink to the corresponding order page.

A nice development that we have implemented is self-made filters that indicate when a plate or wooden line is drawn too long. In our own sawmill, we work with certain standard dimensions of materials, and in the past, it regularly happened that beam and plate material were drawn with the wrong dimensions. Thanks to our new built-in filter, this is now impossible, allowing us to work even more efficiently, avoiding unnecessary work and extra waste.

In short, D’n Herd in Helmond is a complete model in which all the necessary information is contained to bring the project to a successful conclusion and to realize the project as efficiently and with as few mistakes as possible. Partly because of this, we keep the failure costs as low as possible and ensure that a beautiful and innovative building can be realized on-site within a short time.