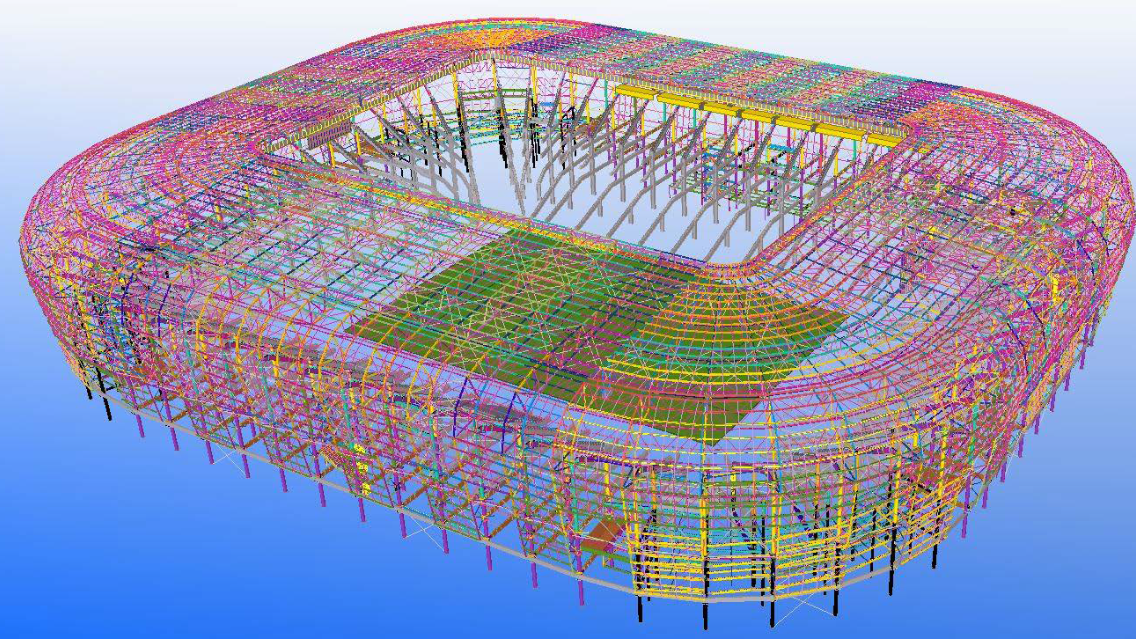

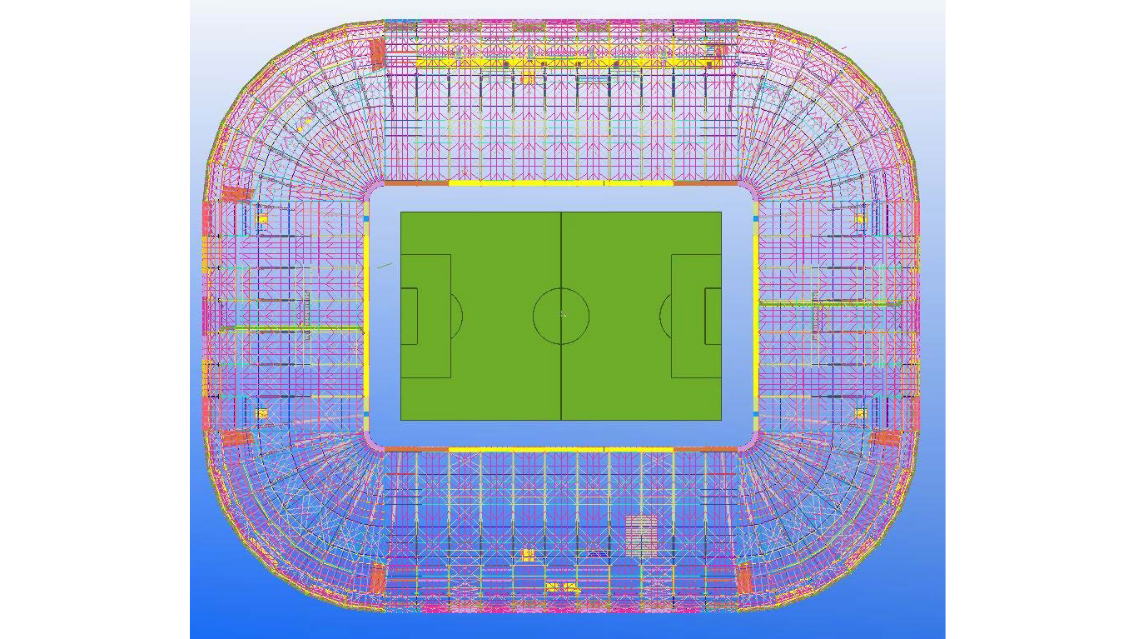

The MRV Arena is a multipurpose sports arena with a capacity for 44,000 people, properly accommodated in the stands, chairs, and boxes. Home of Atlético-MG, Arena MRV won the international "Stadium of the Year" competition for 2023, promoted by the online platform Stadium DB.

About the project

- Approximate weight of 4,200 tons of metallic structure.

- Quantity of Materials: various steels (ASTM A572 Gr50, VM350, ASTM A36, ZAR280, ASTM A108 Gr.B, ASTM A325 Screws)

Challenges and success factors

The main challenges encountered were:

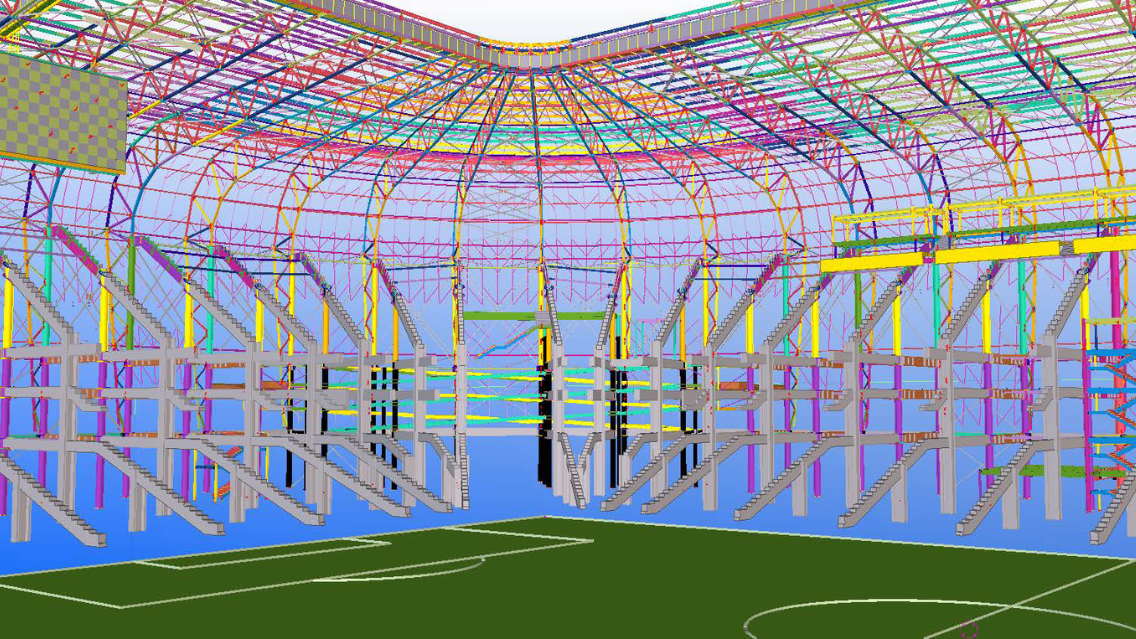

- Metallic structure with large spans, roof overhang of approximately 50m span.

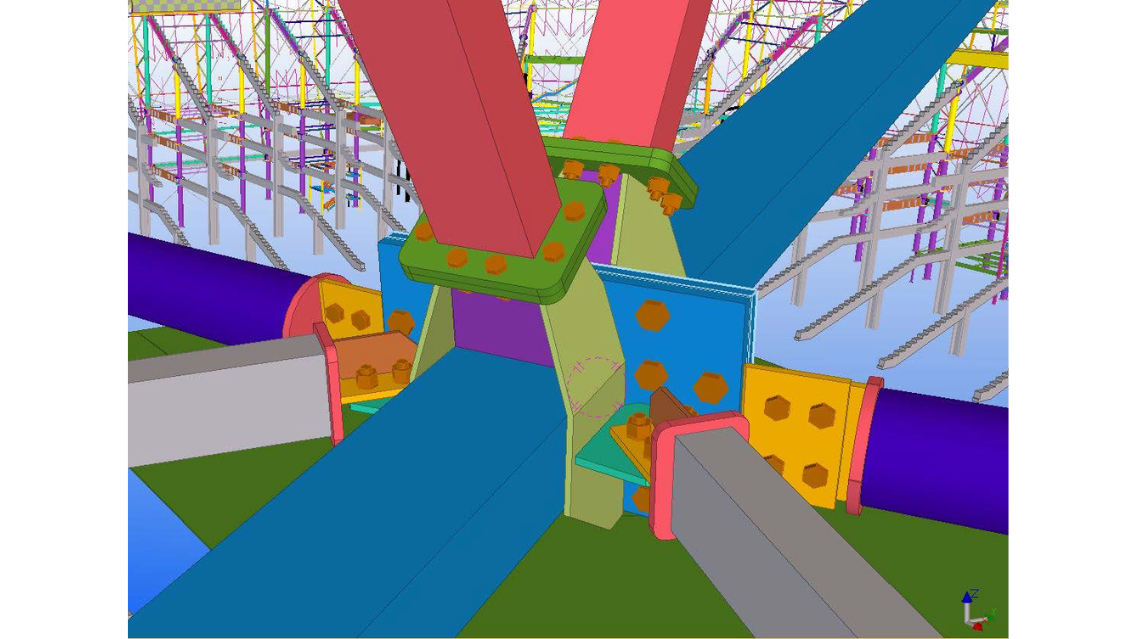

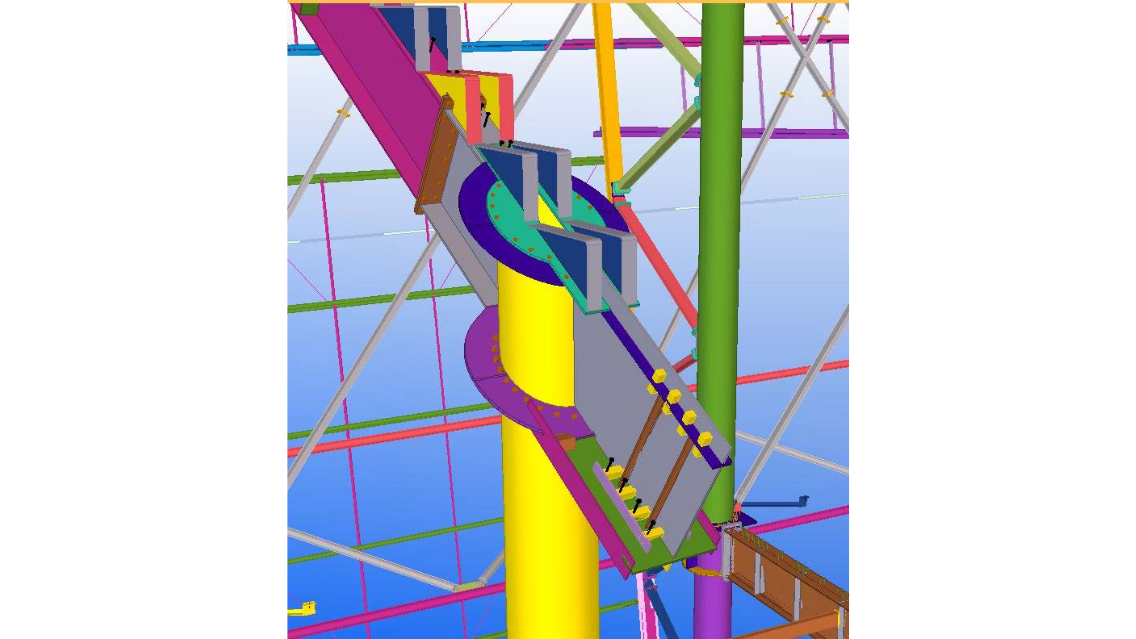

- A hybrid structure, stabilized by metallic frames composed of mixed steel and concrete beams, mixed steel tubular pillars filled with concrete, and the pre-molded reinforced concrete structure, demands the development of innovative engineering solutions through the study of unprecedented mixed connections that were designed and experimentally validated with renowned universities.

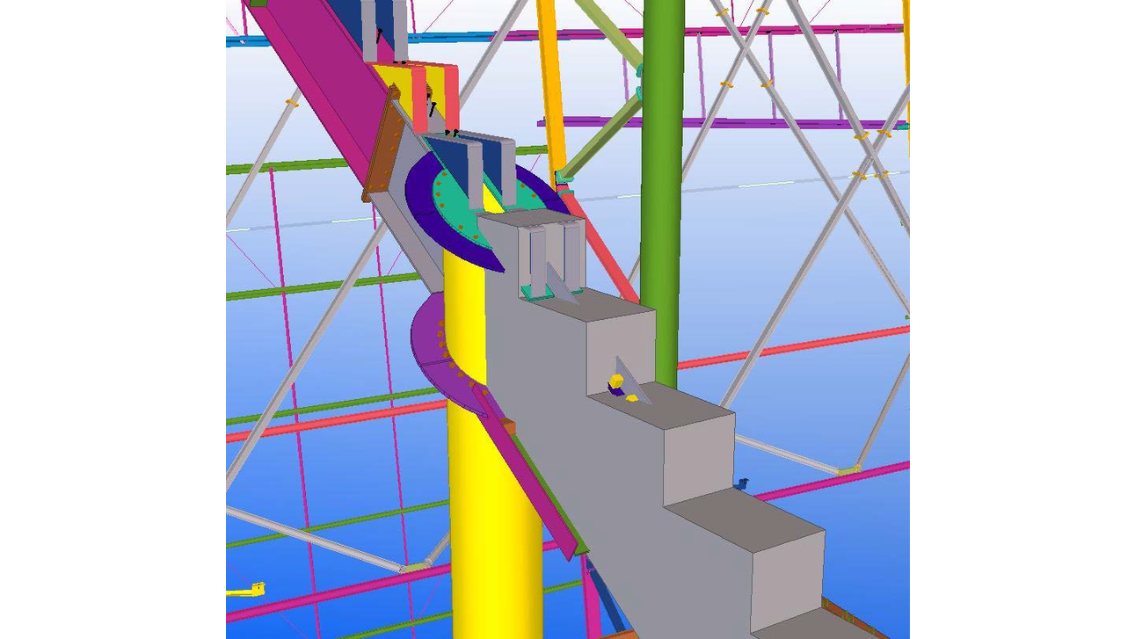

Codeme Engenharia used a highly qualified engineering team, a team of designers and modelers who developed the 3D modeling from the first conceptual works, helping the calculation engineers in the creation of the details, allowing the conception of a highly complex structure and still guaranteeing optimal manufacturing conditions, transport, and assembly.

Success in detailing and phasing allowed logistical flexibility within construction. The detailing and manufacturing based on phase planning and shipment batches allowed excellent service to the final customer's planning demands.

The use of high-capacity cranes and large cranes also allowed versatility on the assembly fronts, and the adoption of fully bolted tubular connections allowed flexibility for assembly teams during the lifting and sequencing of scissor assemblies, bracing, and locking of the metal roofing.

Benefits of using BIM and Tekla

The use of BIM together with the other participating companies, the construction company Racional, end client Arena MRV, architecture FKGV, and precast concrete partner PRECON) allowed for quick and efficient compatibility.

Using Tekla as a modeling and detailing tool was crucial for accurately visualizing all interferences, quickly generating shop drawings and assembly diagrams, and faithfully predicting the weights and positions of the centers of gravity of parts and assemblies. This information is extremely important for preparing rigging plans for lifting heavy parts and complex geometries. Truss sets weighing up to 26 tons were lifted at once using cranes with a capacity of 400 tons.