The Austerlitz basin is a major focus of the campaign to clean up the Seine that has been launched by the capital. As well as the obvious environmental benefits, the open water swimming events - which will bring together the world’s best swimmers in the summer of 2024.

The main aim of this project is to prevent sewage system discharges into the Seine during violent storms, directly improving the quality of the water in the Seine.

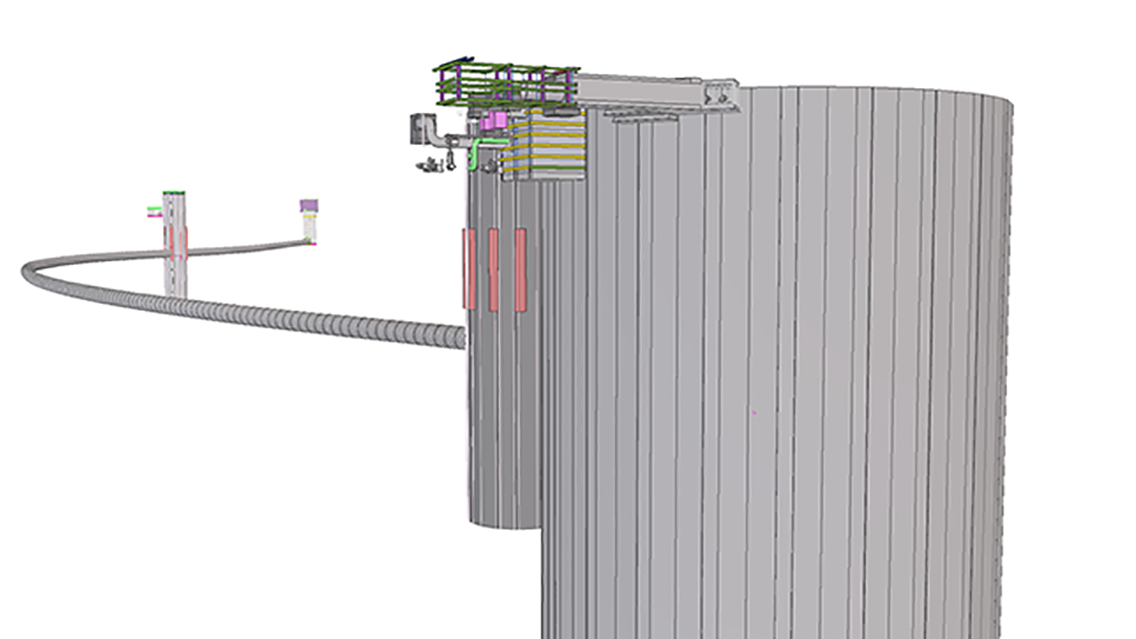

This major project involves the construction of several key elements. Firstly, two water intake structures, located respectively on the left bank (Valhubert well) and the right bank (Tournaire well), will capture rainwater before it reaches the Seine. Next, a storage basin, 50 meters in diameter and 30 meters deep, with a capacity of 46,000 cubic meters, will be built to store excess rainwater. Lastly, a DN 2500 collector, extending over a distance of 625 meters and dug using the microtunneling technique, will link the three aforementioned structures.

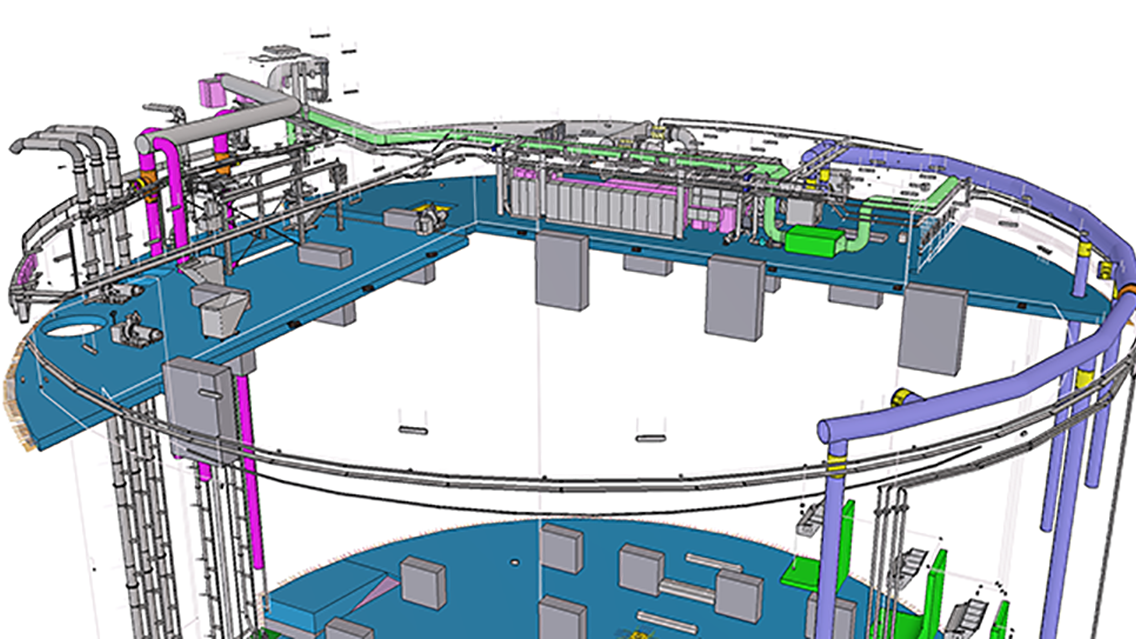

Enser, a specialist company, is in charge of the execution studies for the basin's internal structures, such as the cover slab, internal technical floors, invert and spiral staircase. In addition, Enser is also responsible for the design of the project's ancillary structures, such as the access gallery and the discharge structure, including the shoring of these structures.

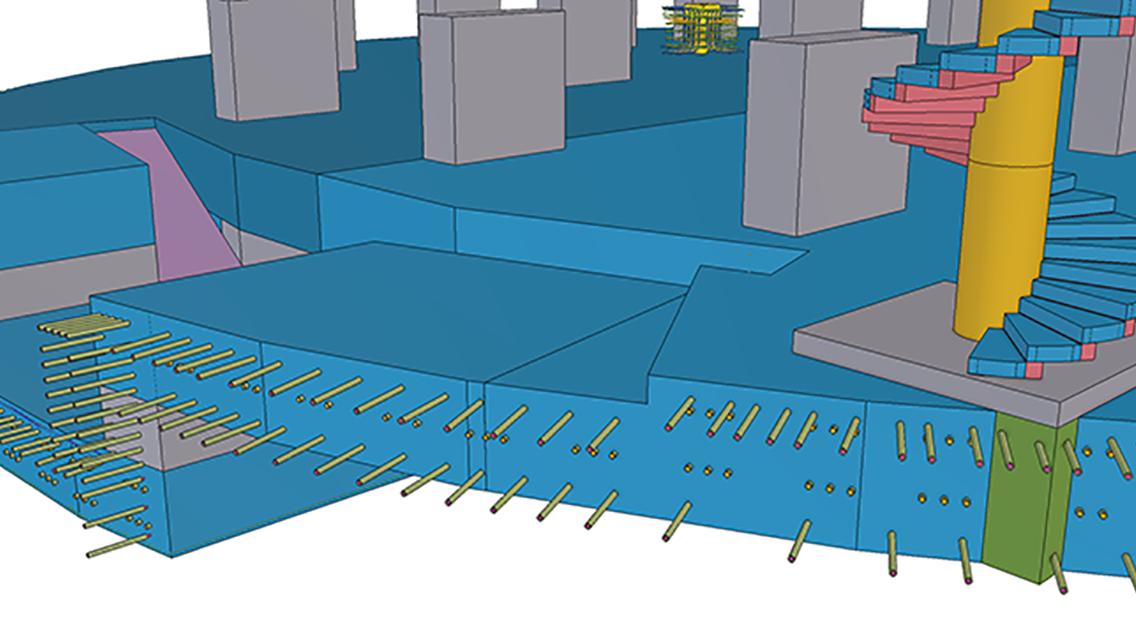

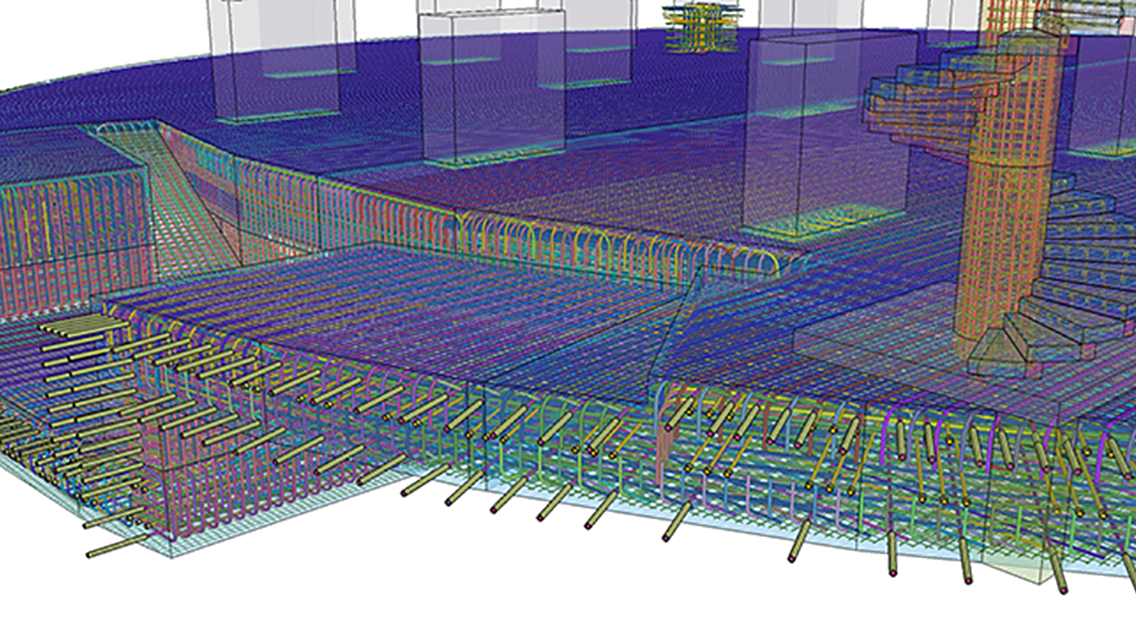

The use of Tekla Structures software was essential to the success of this complex project. Given the large amount of reinforcement required, the complex shape of the structures, and the presence of numerous reservations, this software enabled precise modeling of the reinforcement of the technical floors and the lower raft.

This major project bears witness to the City of Paris' commitment to improving the quality of the Seine's waters, and is an important step towards ensuring a healthy, preserved environment for present and future generations.

The Austerlitz project presented several technical challenges and benefited from a number of key success factors. One of the main challenges was to produce reinforcement plans that could be used on-site, with a high level of detail. The circular shape of the basin, the presence of numerous reservations and the high density of reinforcement, combined with the need to meet construction deadlines, necessitated the use of Tekla Structures for this project.

Thanks to Tekla Structures, we were able to create a detailed model of the reinforcement for the raised access floors and invert. This model was used to generate detailed working drawings, which proved beneficial on-site, helping to minimize errors during rebar installation. The requirement to produce reliable and accurate plans was met thanks to the use of this software solution.

For the internal floors and rafters, due to the scale of the project, we used the Tekla Model Sharing function. This feature enabled us to work in parallel with two to three BIM designers on the project, facilitating collaboration and ensuring model consistency. To model the spiral staircase, we used a Grasshopper model, which was integrated into the structural modeling using SOFISTIK and Tekla software. This approach enabled us to design the complex structure of the staircase accurately and efficiently, exploiting the advanced functionality of Trimble solutions.

Overall, we are proud to have successfully met the technical challenges of the Austerlitz project using Trimble software solutions. The use of Tekla Structures enabled us to generate detailed and reliable working drawings, contributing to the success of the project. In addition, the use of Tekla Model Sharing improved collaboration and productivity, while the integration of Grasshopper with SOFISTIK and Tekla enabled advanced structural modeling for the spiral staircase. These benefits contributed to the overall efficiency of the project and the satisfaction of our team.