At the beginning of 2016, an innovation-minded engineering team from the Virtual Design department at Wagemaker (The Netherlands) was contacted by FP McCann and asked to develop automated engineering tools for a new product range within the FP McCann Group. The goal? That FP McCann can produce its first designs of the Large Sized Chambers and Tanks automatically and use the models for client and production benefits.

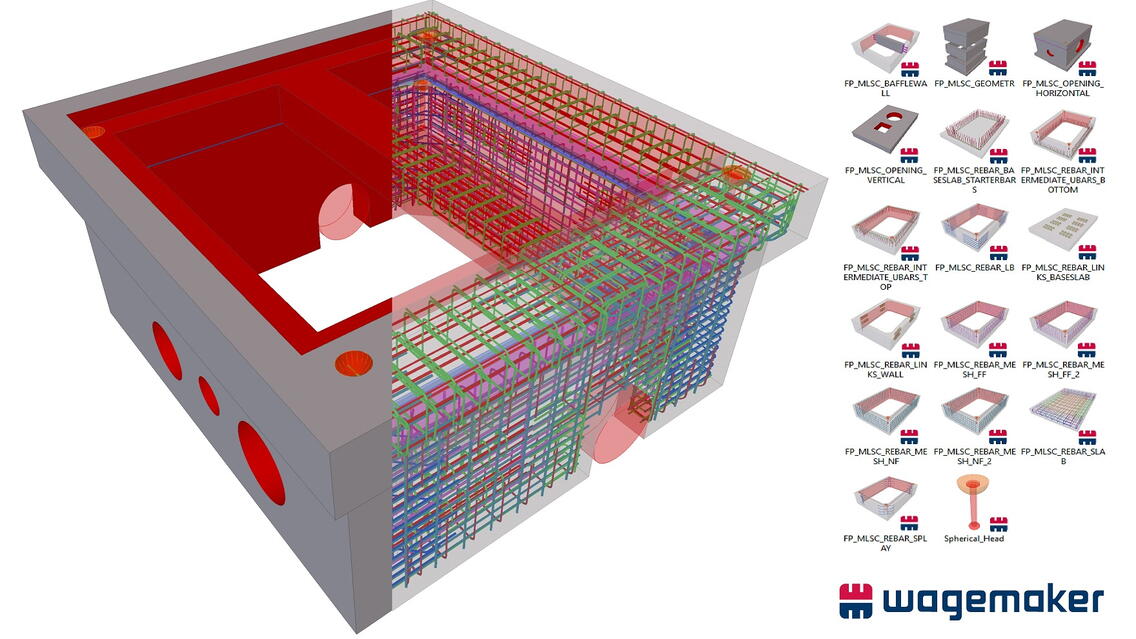

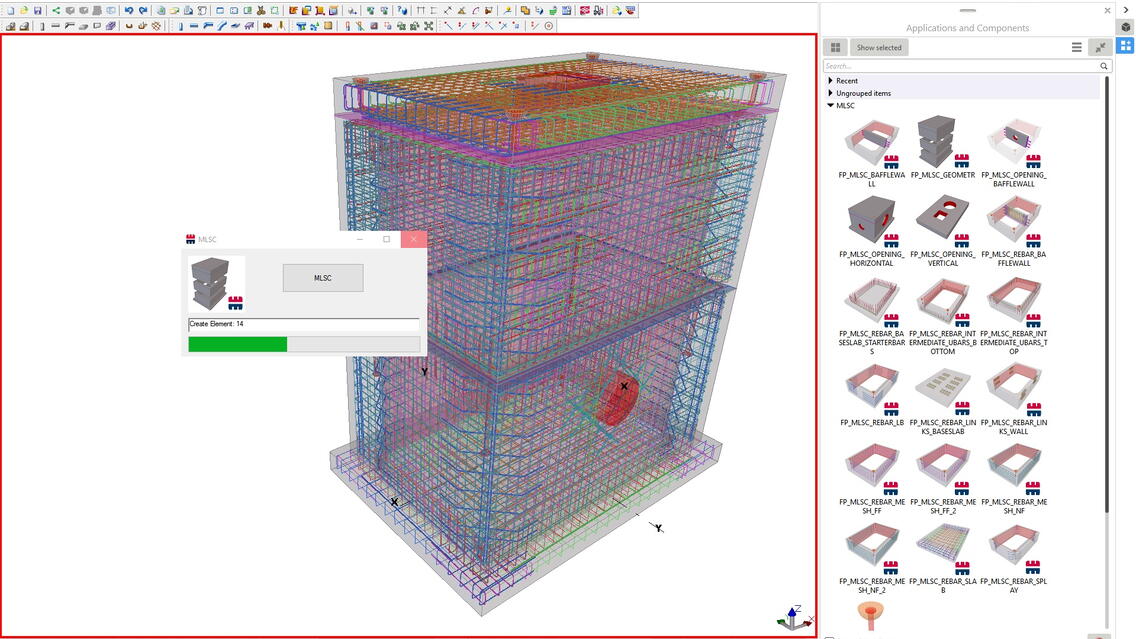

These tanks are engineered with an automated design tool that combines Excel, Tekla Structures and an ERP system. Tekla is used to automatically generate the complete production-ready BIM. Not only can FP McCann produce the models’ data like steering on machines with the digital information, also this model can be used in communication with the clients.

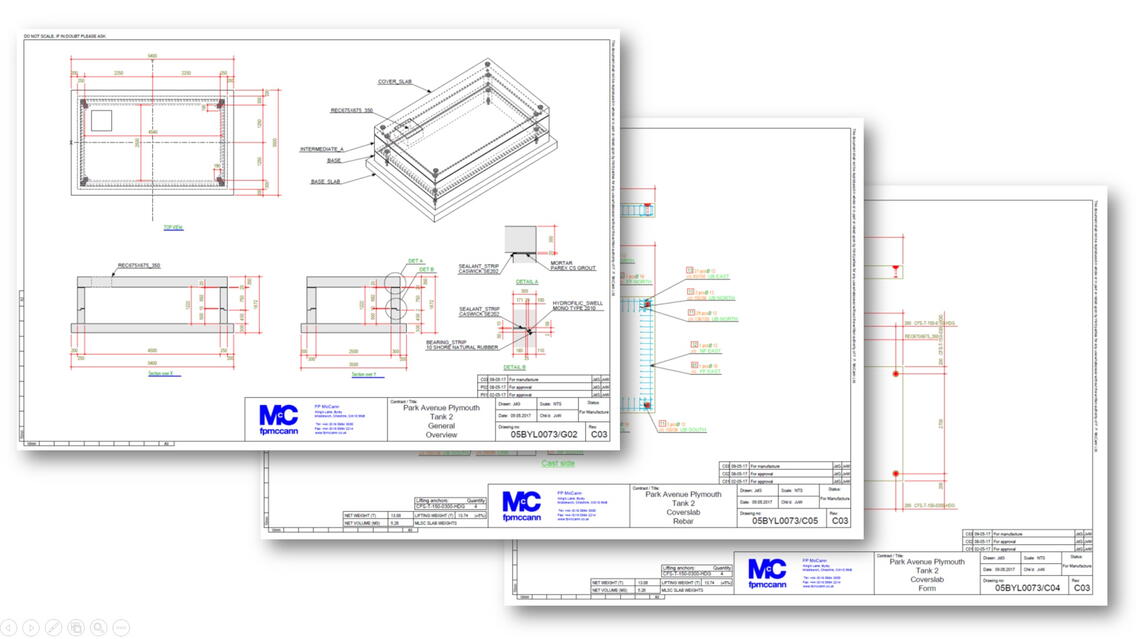

The automation has been set up so the sales team can fill in the parameters for their specific task, which matches the most efficient way of production, but respects the clients wishes for the design. This results in a variety of more than 3,600,000,000,000 different possibilities of chambers. A programmed script makes it possible for the sales team to automatically generate the complete structural calculation, quote, the production ready BIM in Tekla, the IFC, the bill of quantities, the general arrangement drawings and the production drawings.

Together with the team from Wagemaker and FP McCann, we created a complete parametric BIM Automation that sets the worldwide standard in future BIM engineering automation.

Special challenges

The complete automation of the structural calculation and the creation of the Tekla model had to work with no human interference. Wagemaker created a smart modular process to achieve this. The tools made are open and flexible for future use. Furthermore, Wagemaker created a system that can also can be used when a project does not entirely fit the standard concept. What’s more, the automated calculations had to match the UK standards. Together with the technical staff from FP McCann, the structural engineers from Wagemaker turned this challenge into a futureproof solution.

What made the project successful

The completion of this project was a result of one very important fact: the innovative team with dedicated engineers who have a clear view on the future of the building industry worldwide. Also the partnership with the FP McCann team was crucial. Taking back design to the basics and detailing from an automation point of view with some common sense created a simple but easily repeatable design, essential for precasters like McCann. The team had fun, worked hard, did what had to be done, and worked very precisely. We combined ICT and engineering to the fullest. We created proof that Tekla can be used for disruptive innovation in the engineering sector. All team members look at precast concepts differently now. We feel the urge to share this knowledge with the world.