Description

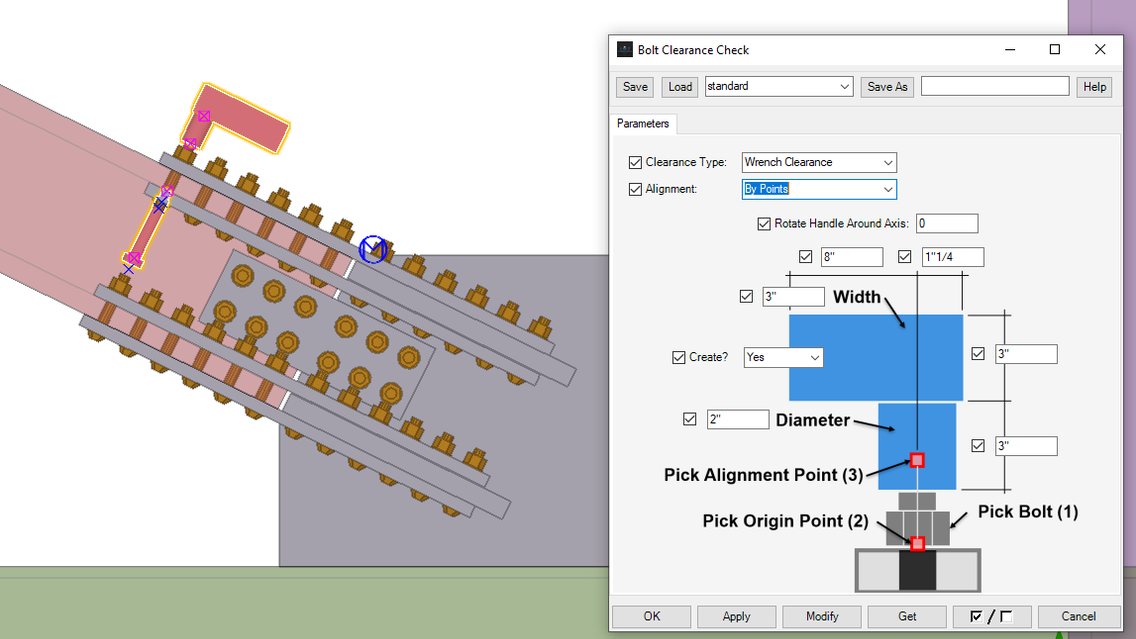

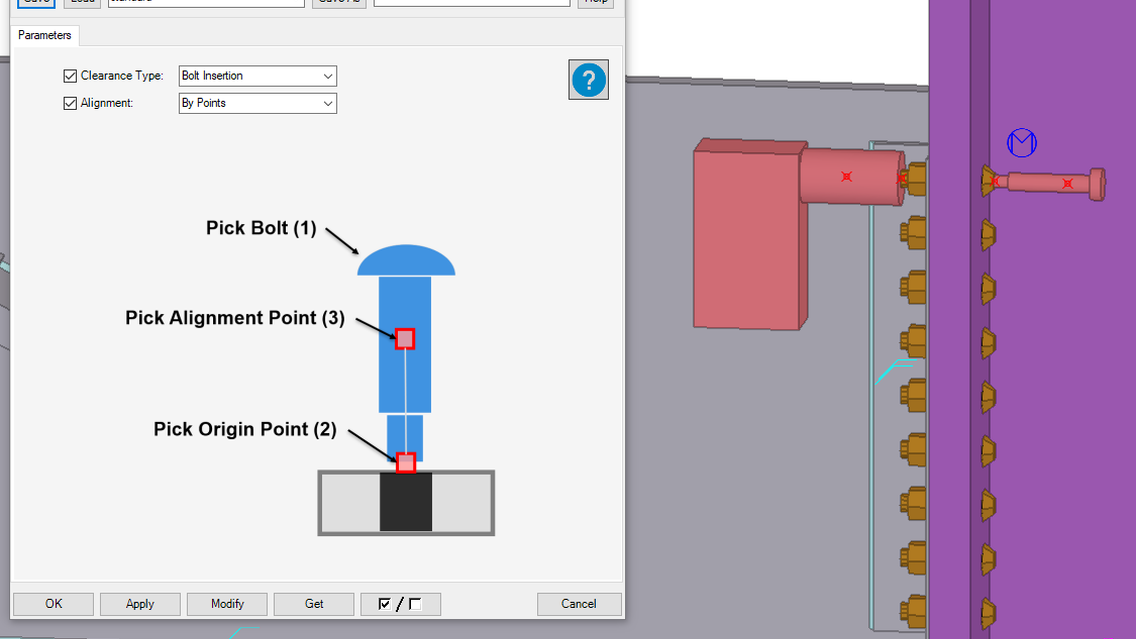

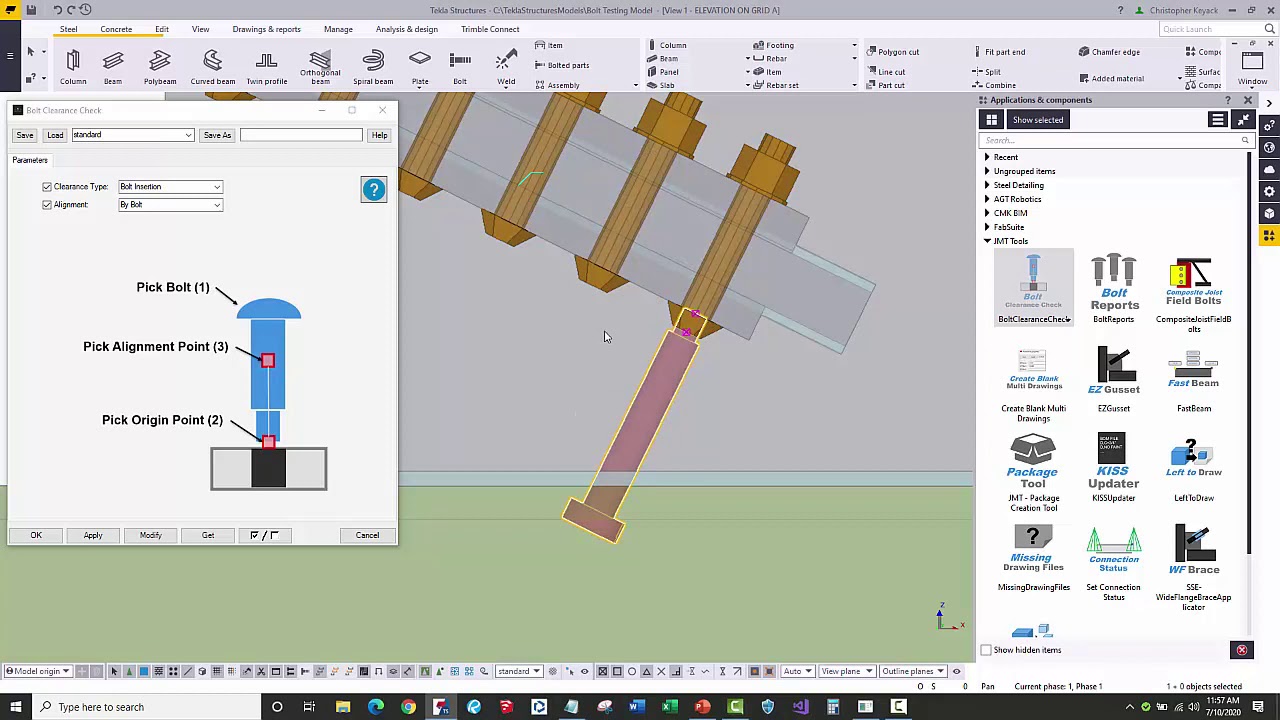

This plugin allows Detailers and Erectors to place a temporary bolt or wrench in the model to check for installation clearance.

For TC (Tension Control) bolts, it will include the spline. You can choose to pick two points or align with the direction of the rotation on the bolts. The wrench can be customized and rotated around the bolt alignment axis. This is a plugin so it is parametric and adjusts with the bolt properties and length. This is designed to work primarily with US bolts.

We also published this model with the bolt and wrench to Virtual Reality and visualized this with the Oculus Quest VR headset. This allows us to actually feel the ergonomic impact that tight clearances might have.

Problem that app solves

The Tekla Structures model doesn't completely show the true length of TC bolts because Tekla Structures doesn't show the spline on the end of the bolts. So detailers can often fall into the trap of not looking at the real length of a bolt to make sure it can be inserted.

Also, it is hard for detailers to check if electronic wrenches can be inserted into tight connection framing areas to see if the bolts can even be tightened. By not checking this early on during detailing, the erector may have a difficult or impossible time not only tightening the bolts, but also inserting the bolts into a connection. This can cause unexpected field welding or using slow hydraulic wrench to deal with tight clearances.

This application make is easier for detailers to catch this before things go to the field.

Feedback

We have been able to change connection design early on the project before getting to the field and connections not being able to be bolted with an electric wrench. This prevented unexpected delays in the final field bolting schedule that the Erector wouldn't have seen until they were in the field.

Development project

We quickly created a spec and coordinate with our in house detailing project managers. We then did a kick off meeting with our in-house developer to show them how things are done out in the field with bolting videos and field images. We then showed the developer how this would be manually modeled so they can easily understand how the code should automate it.

We have in-house automated code generators tools that create all of the code from the UI form design and then creates the backend plugin code structure. This automated UI linking to the backend code saves a ton of time and prevents errors between the UI and business logic.

Submitted by

Christopher Keyack, JMT Consultants, US

About the company - JMT Consultants

Steel Detailing and Connection Design. We have leveraged the API since it's conception in the mid 2000's.