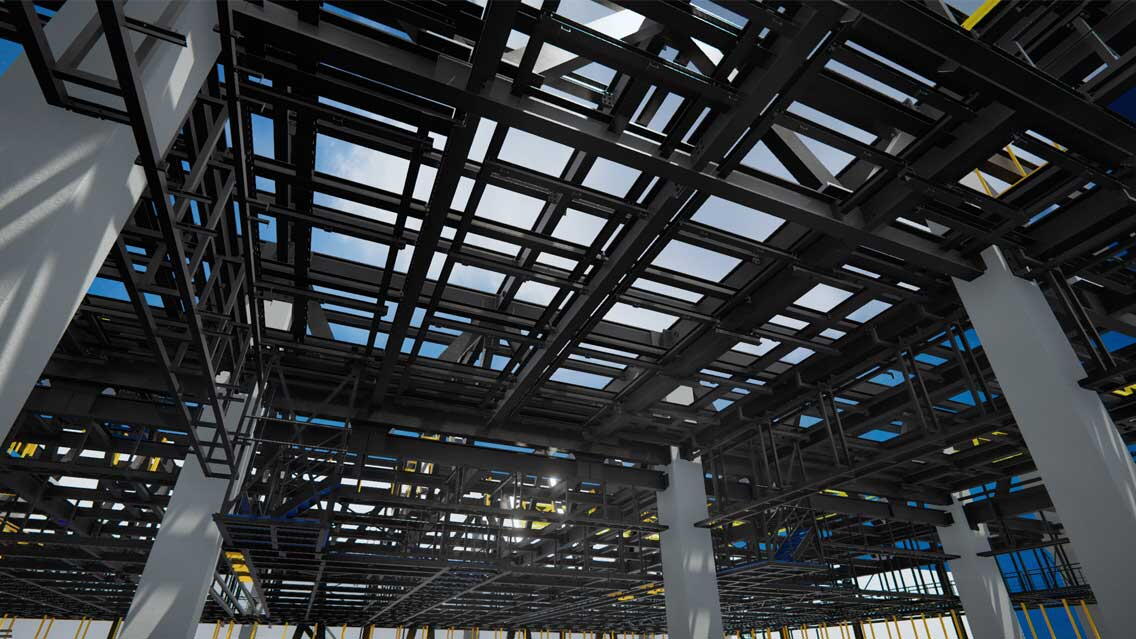

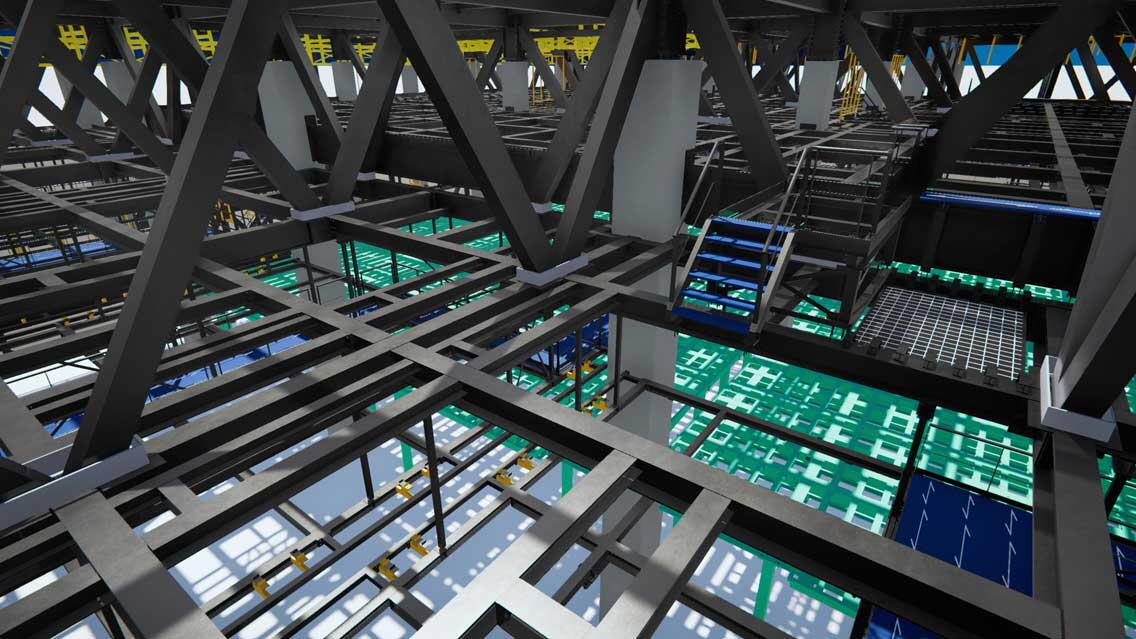

The structure is unique, as it’s built on 30x concrete columns. Steel columns are mounted on these concrete columns, supporting 34x steel trusses. The trusses support the entire steel structure.

Key numbers:

• 2500 Tonnes of steel

• 34 trusses

• 56.000 bolts

• 1279 gratings and steps

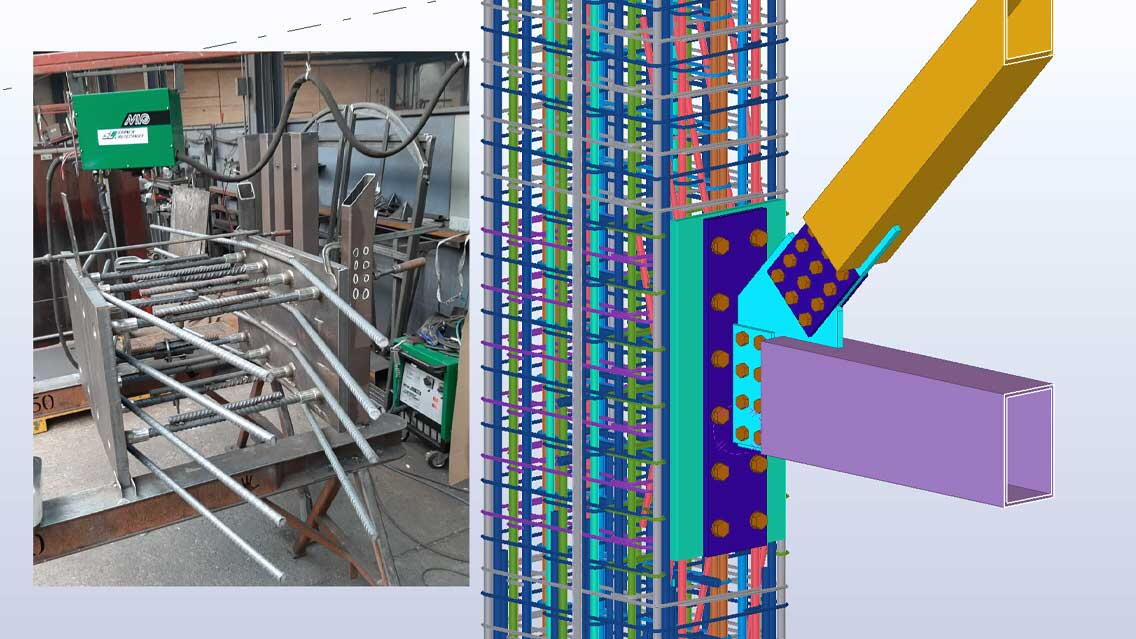

• 663x IFC models / 2D DWG files (118x up to date)

The project was set up by the main structural engineer and the architect. The final implementation was undertaken during the construction process. The client, construction contractor, architect, constructor, installer, concrete suppliers, and of course, the steel constructor, communicated with each other with IFC models.

Weekly meetings and alignments of multiple disciplines on a project of this size would have been impossible without 3D IFC models. While coordinating an effective 3D approach, it remains a challenge to work with parties that do not work with a 3D package. 2D must be checked with 3D, so you are constantly running behind updates and new information, making the approach far more prone to error.

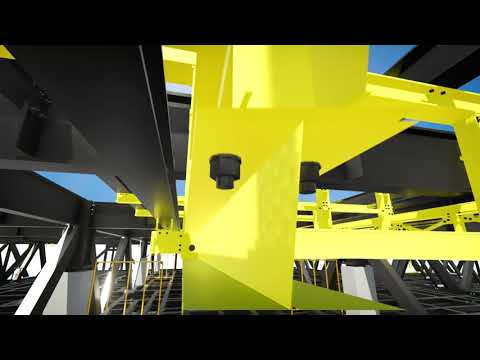

BIM is also becoming more popular on the building site. Mechanics will still receive a 2D drawing, but a tablet with Trimble Connect is the starting point. Trimble Connect always contains the latest IFC models and associated overview drawings. Updates come automatically, along with daily email notifications.

Because the entire steel company works on one project with the same data in Trimble Connect, modelers, assembly teams, project leaders, and calculators are always provided with the latest information.

With the 3D possibilities now available, I am amazed that many parties still work out and deliver everything in 2D. Workers on construction sites still tend to use traditional drawings and lists written on paper. The importance of BIM and IFC models is gradually becoming recognized on construction sites.