Newest skyscraper addition to the Philadelphia skyline

Comcast Technology Center is the newest skyscraper addition to the Philadelphia skyline.

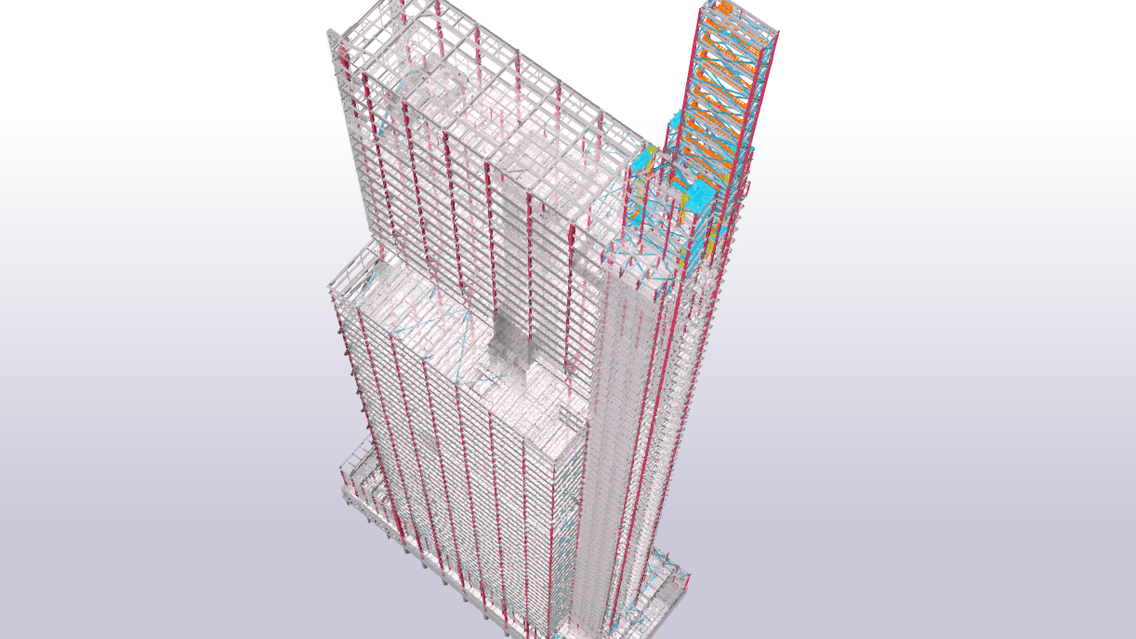

Towering over the city at a height of 1,121 feet, it has become a part of American History not only as the tallest building in Philadelphia, but as the tenth-tallest building in the United States and as the tallest building outside Manhattan and Chicago in the US. The 60-floor building includes approximately 1.8 million square feet with a total steel tonnage estimated at 20451 tons.

Instead of the traditional center-core high-rise for its new skyline-defining tech center, another design was proposed. It included open, Google-like spaces for creative employee collaboration with a center core that would cut through the open spaces. To do so, Foster & Partners shifted the core to the 19th Street side of the tower’s footprint – what structural engineers call an ‘eccentric’ or ‘off-center’ core. That opened the office floors on the eastern side of the tower.

Not only did Foster & Partners insist on an off-center core, it went one step further. It designed a split off-center core, or an off-center core divided into two parts. This is, conceptually, two concrete boxes running vertically up the building for stability. To stiffen the top floors, which were the most susceptible to powerful wind factors, Thornton Thomasseti’s engineer team, led by Andrew Blasetti, incorporated ’chevron braces’ on the hotel complex's east and west sides. The engineering team buried the A-shaped steel braces between hotel rooms so they cannot be seen or noticed. They are stacked on the east and west sides of the hotel, one brace on top of another.

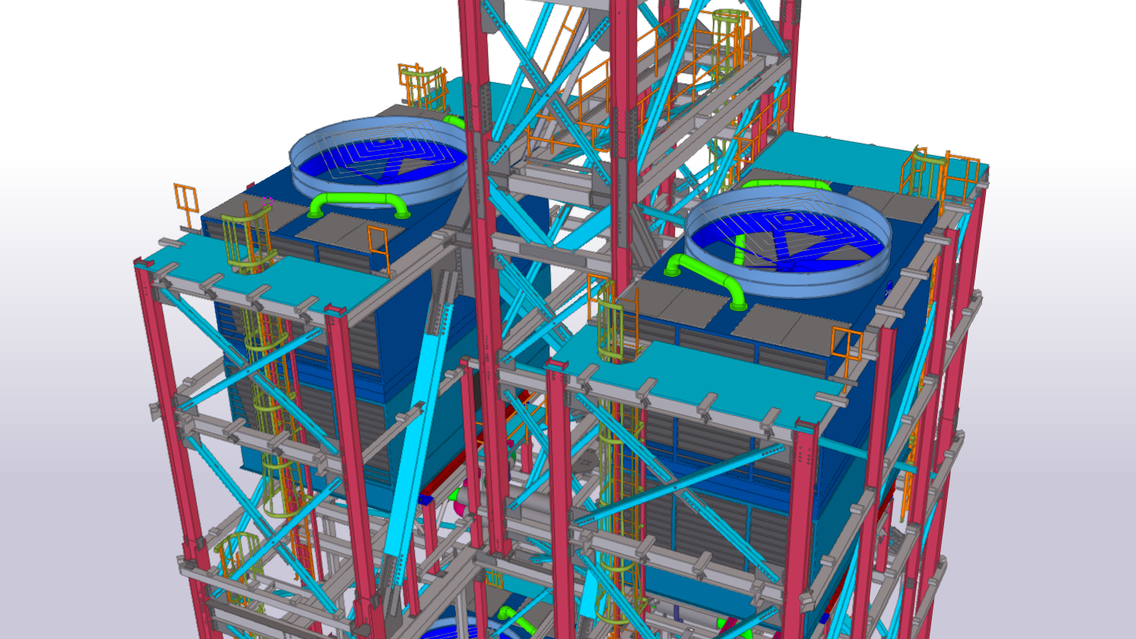

Blasetti's team also allocated space for five ’tuned sloshing dampers’ in the ceiling of the 57th floor, below the hotel sky lobby at the top of the building. The five dampers - holding 125,000 gallons of water - will act as a countervailing force when the tower sways in the wind. They will be hidden in compartments in the ceiling.

Benefits from utilizing BIM and Tekla Software

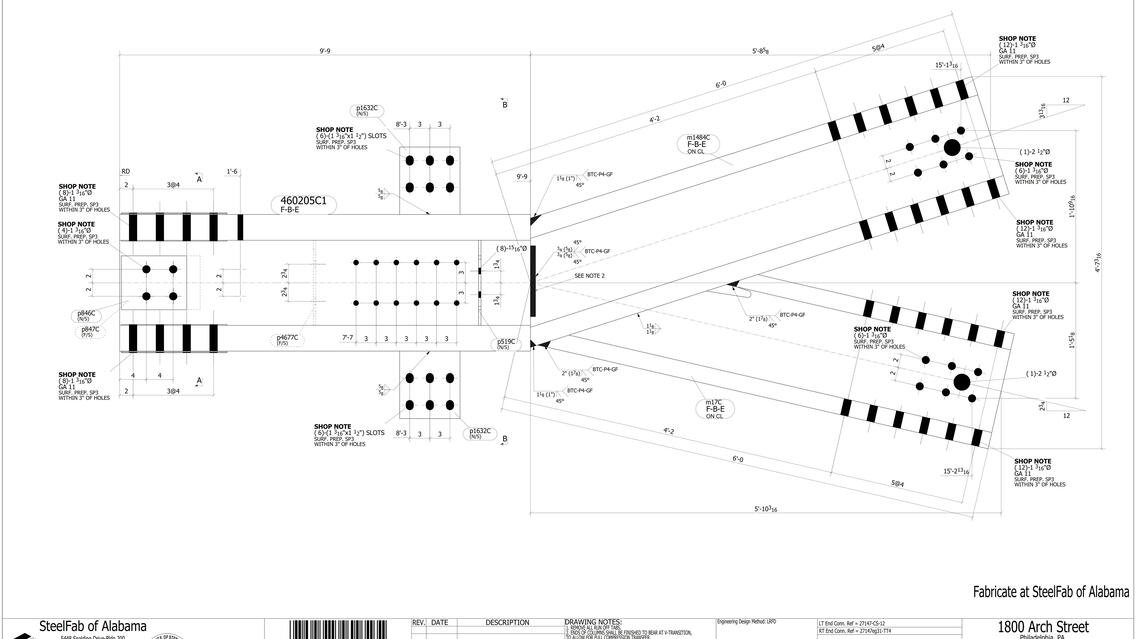

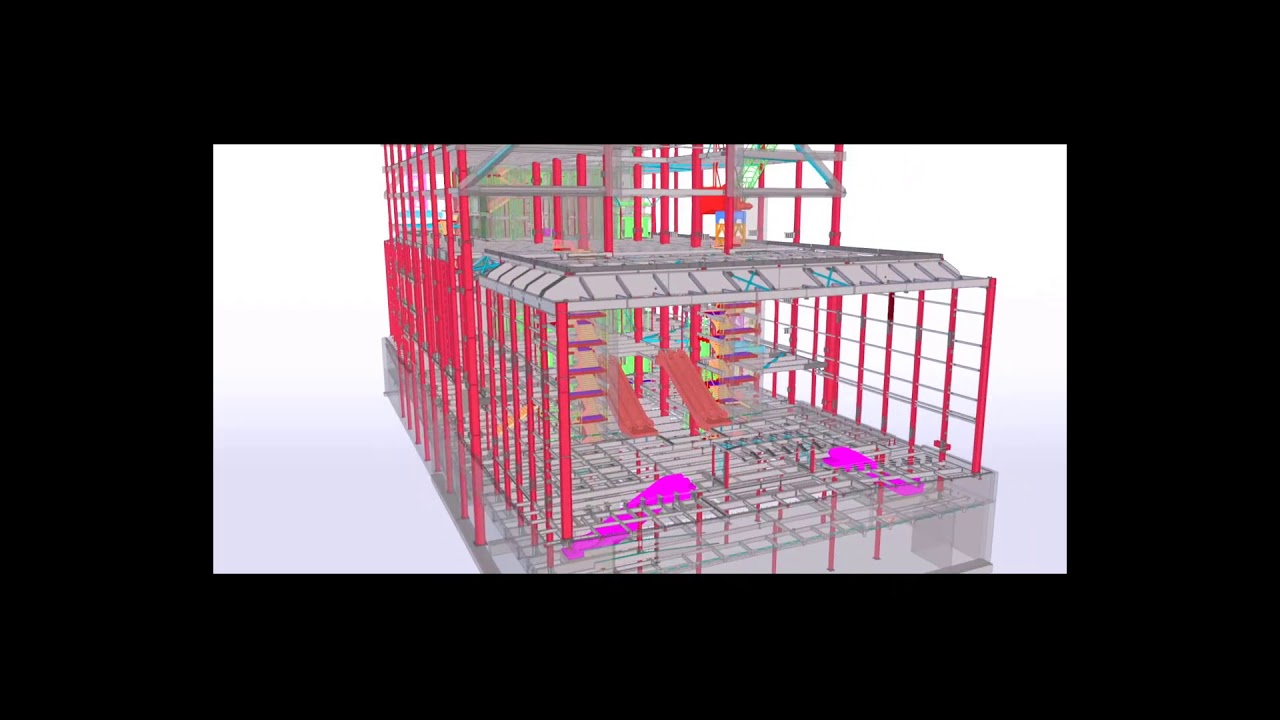

Thanks to the intelligent approach of BIM coordination, steel detailers from Prodraft Were able to anticipate any problems ahead of time by using lightning-speed import/export of reference models exchange with other trades using the Tekla Structures software environment. Prodraft, who also detailed the winner of the 2017 IDEAS2 award in the ‘Over $75 Million’ category for the Smithsonian NMAAHC, used a fragmenting approach to speed up the fabrication process, dividing the structure into separate models that could be detailed simultaneously ahead of time.

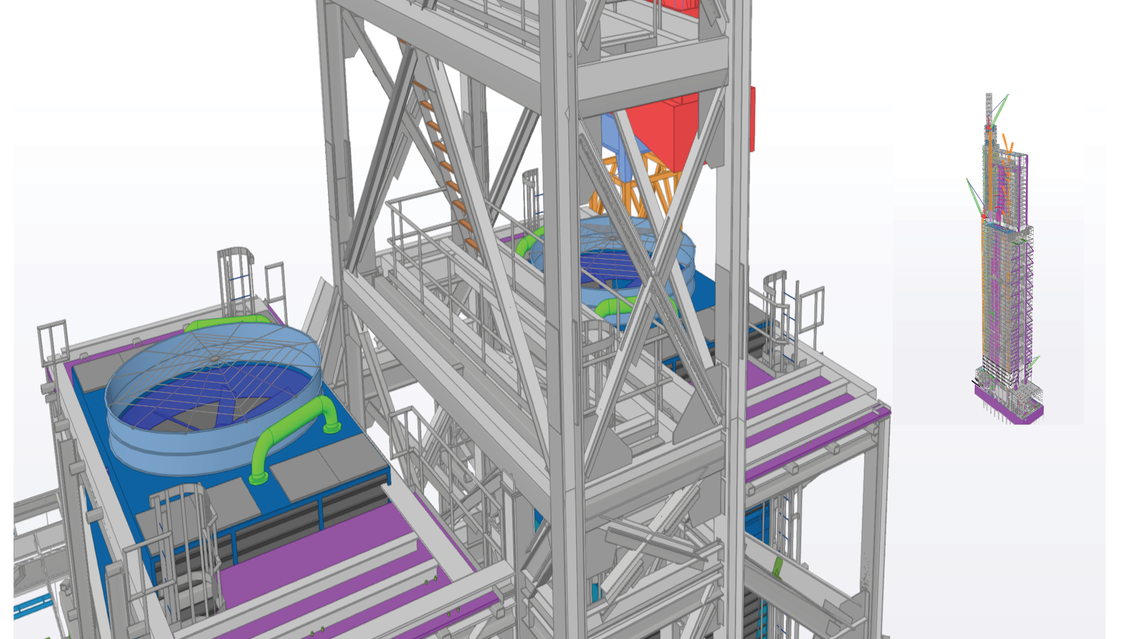

All other trades based their coordinative models on the main Tekla model used by the detailers. This project’s BIM coordination included: A completely separate design incorporating the crane support structures for 3 exterior and interior cranes which rose along with the building throughout all of the construction process. This required an enormous number of steel struts in order to maintain the crane.

- a special safeway freight elevator structure which also rose along with the building, used for transporting people and materials for upper levels of the building. It was later disassembled after finalizing the project. - over 20 elevators using the destination dispatch technology

-rail and cart installations located on the roof used for cleaning the exterior of the building

-the enclosure structure used for the external peripheral design for steel covering, which required tens of thousands of connectors

-steel-to-concrete connections which required nearly 8000 embed elements

This project was presented during SteelDay 2017, an annual celebration of the structural steel industry sponsored by AISC. It is the largest educational and networking function, with events occurring all over the country.

“A world-class building, designed by a world-class architect, built by a world-class developer for a world-class company, all happening in the world-class city of Philadelphia. This building will serve as yet another physical monument to the transformation of this city (..) Congratulations to all involved in this project” – Michael A. Nutter, Mayor of Philadelphia

Challenges

-Load Path: One of the greatest challenges for structural engineers is to determine the direction of the load path in skyscrapers. How does weight on the tower’s floors find its path downward from floor to beam to column to core wall to foundation and, finally, to bedrock? One would think finding this path would be trickiest on the uppermost floors. But that's not so. Even though distance for the weight to travel to bedrock is longer at the top floors, the weight has a more direct path through the lattice of beams and columns. "The lower podium levels, as with most large projects, have more complicated load paths due to the number of steps in the floor plate. It's very common for retail/lobby spaces to have numerous elevation changes across the floor," Blasetti said in an e-mail conversation, noting later that escalators also complicate load-path calculations. "The challenge is tracking this load to each of the surrounding columns to figure out what percentage goes where. This is a very important step, as it affects the column and foundation designs.

-Wind: A wind-tunnel test on a scale model of Philadelphia by the Alan G. Davenport Wind Engineering Group at the University of Western Ontario confirmed suspicions of the structural engineers that a strong northeast or southeast wind could whip around the Comcast Center and slam the new tower's top floors. To stiffen those floors, Thornton Thomasseti’s engineer team, led by Andrew Blasetti, ’chevron braces’ on the hotel complex's east and west sides. The engineering team buried the A-shaped steel braces between hotel rooms so they are not seen or noticed. They are stacked on the east and west sides of the hotel, one brace on top of another. Blasetti's team also allocated space for five "’uned sloshing dampers’ in the ceiling of the 57th floor, below the hotel sky lobby at the top of the building. The five dampers – holding 125,000 gallons of water - will act as a countervailing force when the tower sways in the wind. They will be hidden in compartments in the ceiling. "The architectural design for this building is very tight – there is no dead space," Blasetti said.