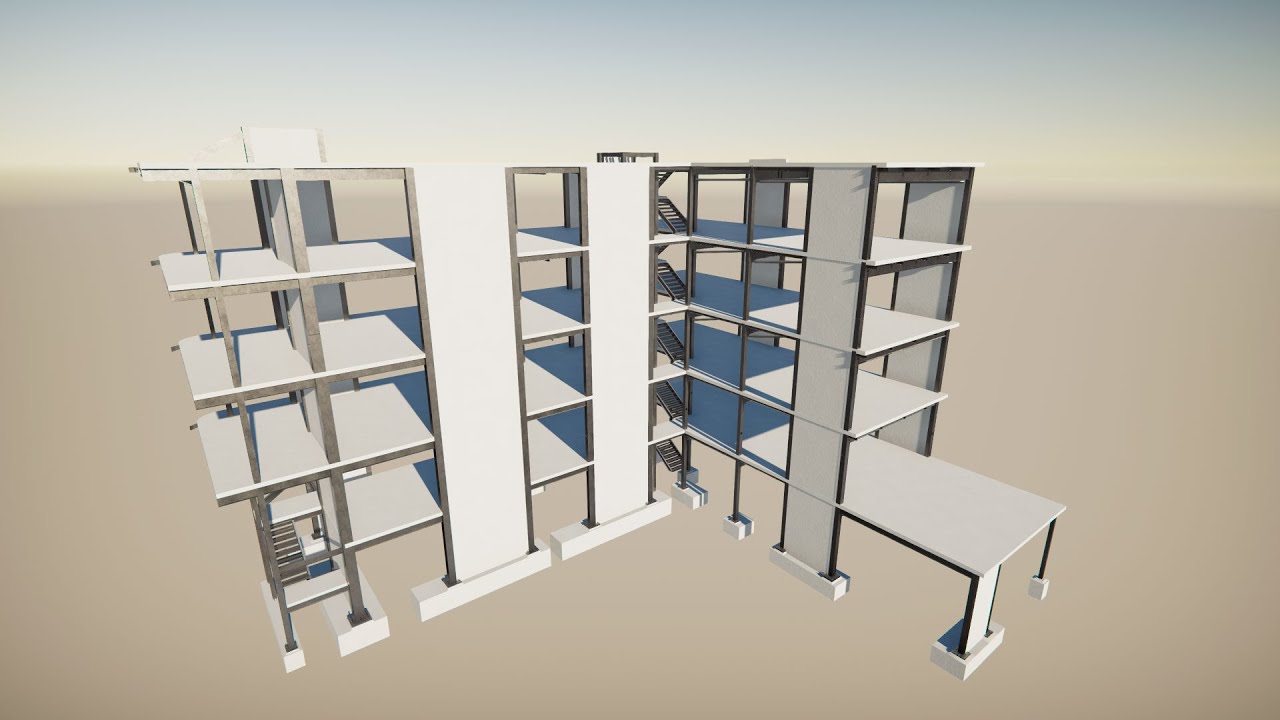

Location: Apartadó, Antioquia (Colombia)

Width: 27,5m

Length: 24m

Hight: 19,5m

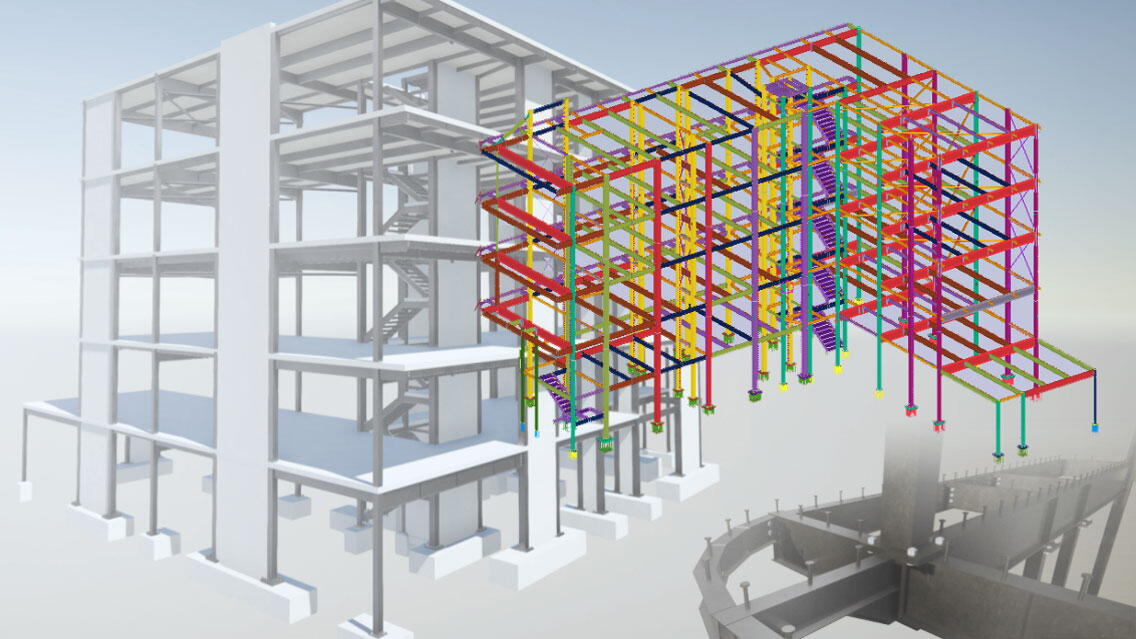

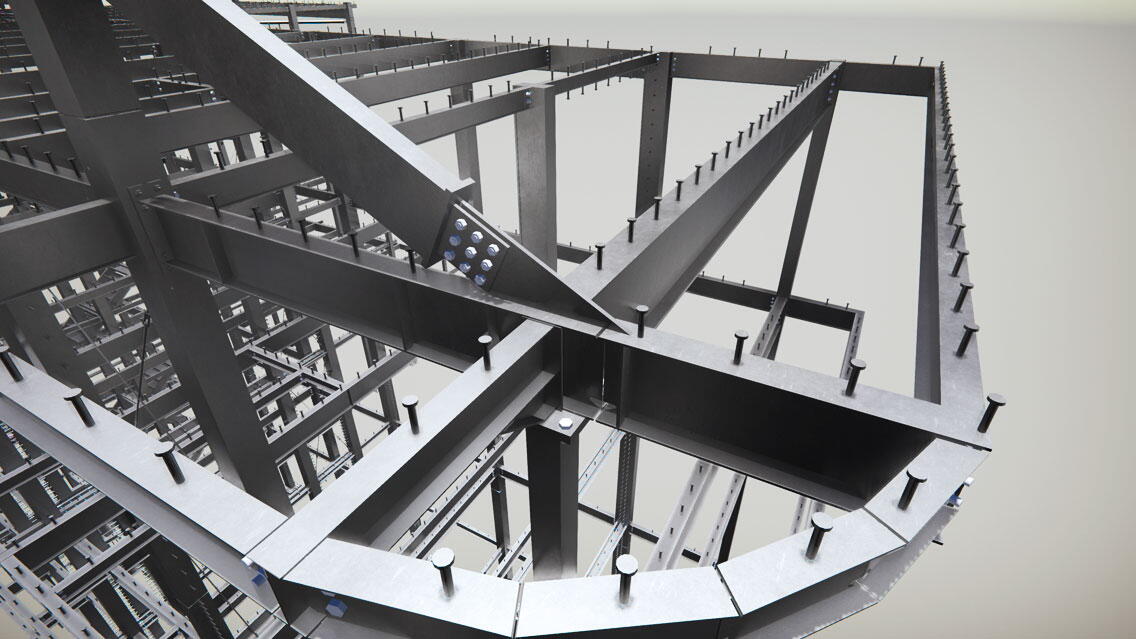

This project has an approximate total weight of 102 tons and was connected by 2676 bolts. With a structural design duration of three weeks, it began with the creation of a structural model from the importation of a model with the profiles that would be required to carry out the work (created in Etabs Software) and ended with the generation of at least 233 manufacturing drawings.

The 3D model is made up of 16,646 parts of shear connectors, all the laminated steel profiles, and sheets in grade ASTM Gr.36 and ASTM A572 Gr.50, forming a total of 2.053 assemblies. Detailing the model for this project required three detailers, which were distributed as follows:

- Detailer (A): Modeling of steel for foundations and structural walls as well as foundation design drawings

- Detailer (B): Main Structure

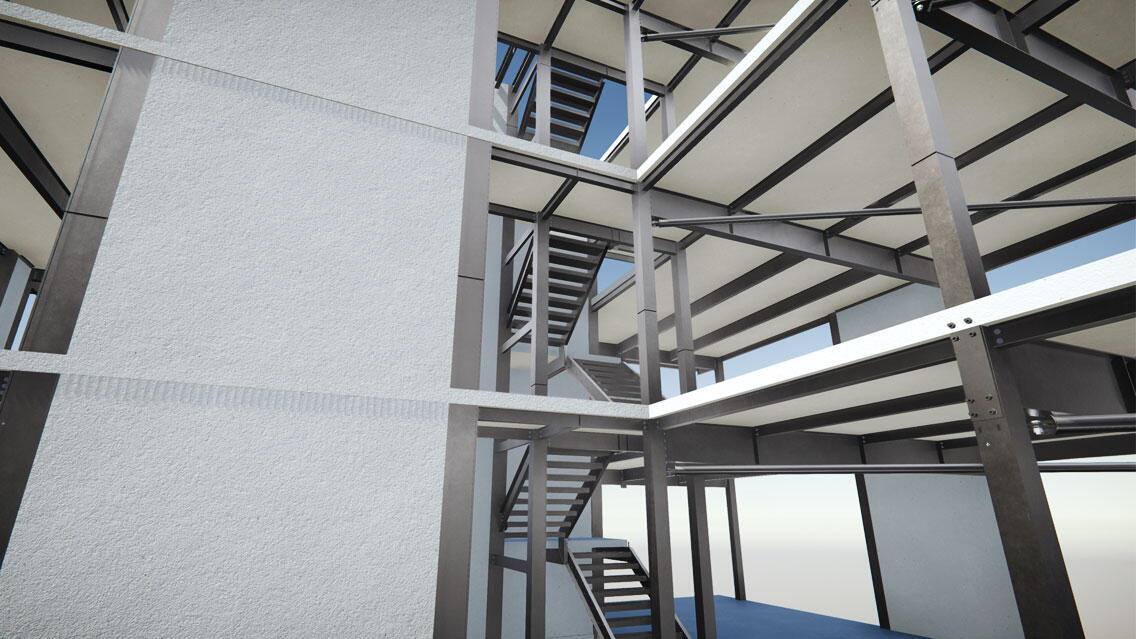

- Detailer (C): Stairs

Three draftsmen were required for designing, manufacturing, and creating assembly plans, which lasted three weeks and began to be carried out after the detailer manager of the project carried out crash control, the numbering of parts and assemblies, and generated the lots according to the requirements by assembly area. Finally, the CN and DXF files for the CNC machines we use in our manufacturing plant were generated.

Four weeks were needed for the elaboration of the structure in the manufacturing area. All the elements were later transported to the site of its construction according to the previously assigned lots.

The erector area needed nine weeks for the assembly of the structure, which started during week two of manufacturing. During those nine weeks of assembly, the following functions were also carried out at the assembly site; the construction of structural shear walls, slabs, filled composite columns, and other details.

Programs Used

- Tekla Structures for making the model, manufacturing, design, parts, and assembly plans

- STRUMIS as information manager to minimize overhead and costs and maximize productivity and profitability

Data of Interest

- 2676 bolts

- 16646 parts distributed in 45,000 Assemblies.

- Simultaneous work between the participants during the development of the project

Model Participants

The model was completed in three weeks by eight people:

- One project manager

- Three detailers for modeling

- Three draftsmen