The concept is an original company process: prefabricated concrete houses are delivered turnkey in five months. We control the entire pavilion chain.

The architectural design office and the sales team create a model and plans for a custom-built pavilion according to the customer's wishes. Once the CCMI has been signed and the building permit accepted, the design office takes charge of sizing the structure and drawing up the manufacturing plans. The production department then collects the manufacturing drawings and produces the prefabricated elements in the factory. Finally, the construction department coordinates the assembly of the pavilion.

Challenges to meet

We chose Tekla for our housing business five years ago.

Initially, we wanted software that would enable us to produce more plans while increasing their quality and detail. Thanks to our customized components, we've succeeded in doing just that.

For example, our teams can design an 80m² single-story bungalow in 2/3 days. For larger bungalows >200m² with elaborate architecture (i.e., +150 plans), the design process can take up to a fortnight.

Next, we wanted to introduce the use of digital technology directly on-site. Site managers have now achieved this with the use of Trimble Connect. They have access to the IFC model, general plans and fabrication drawings.

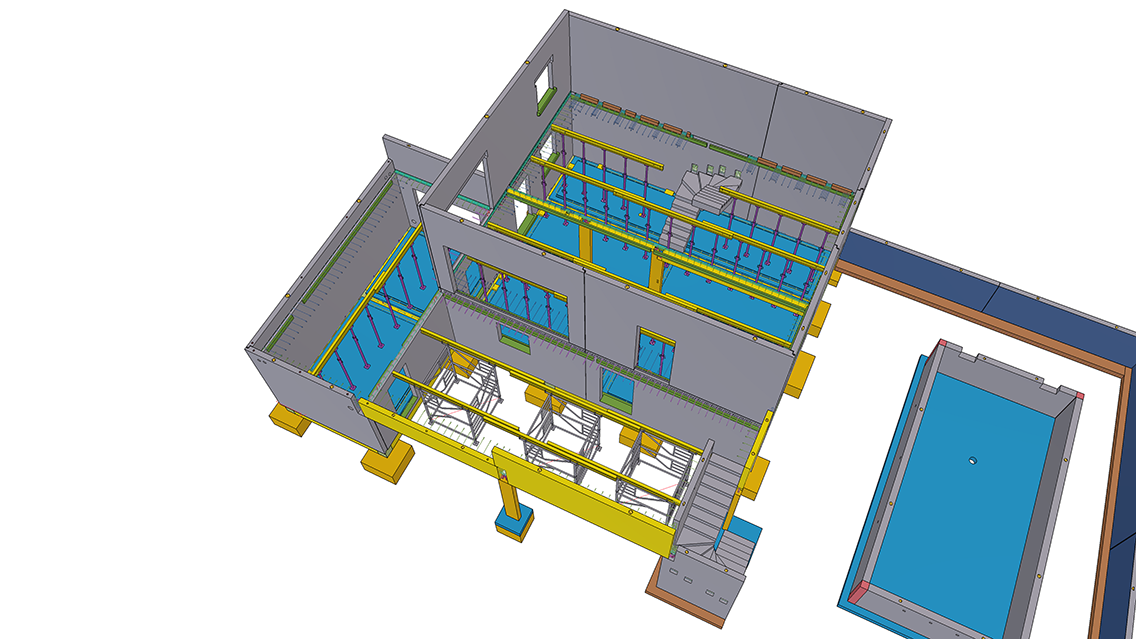

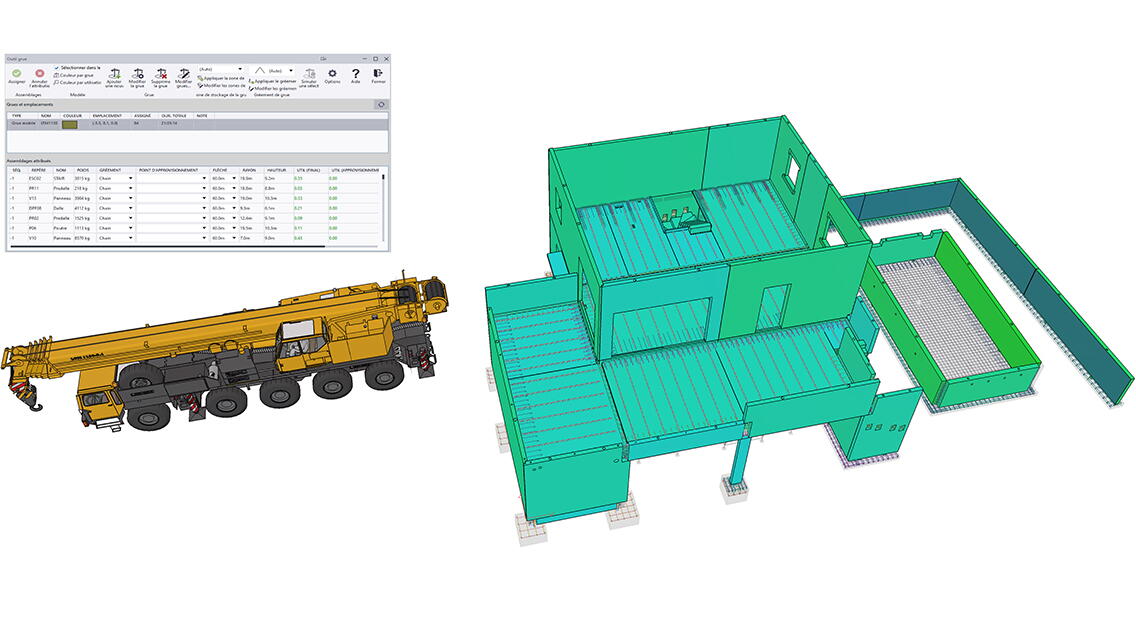

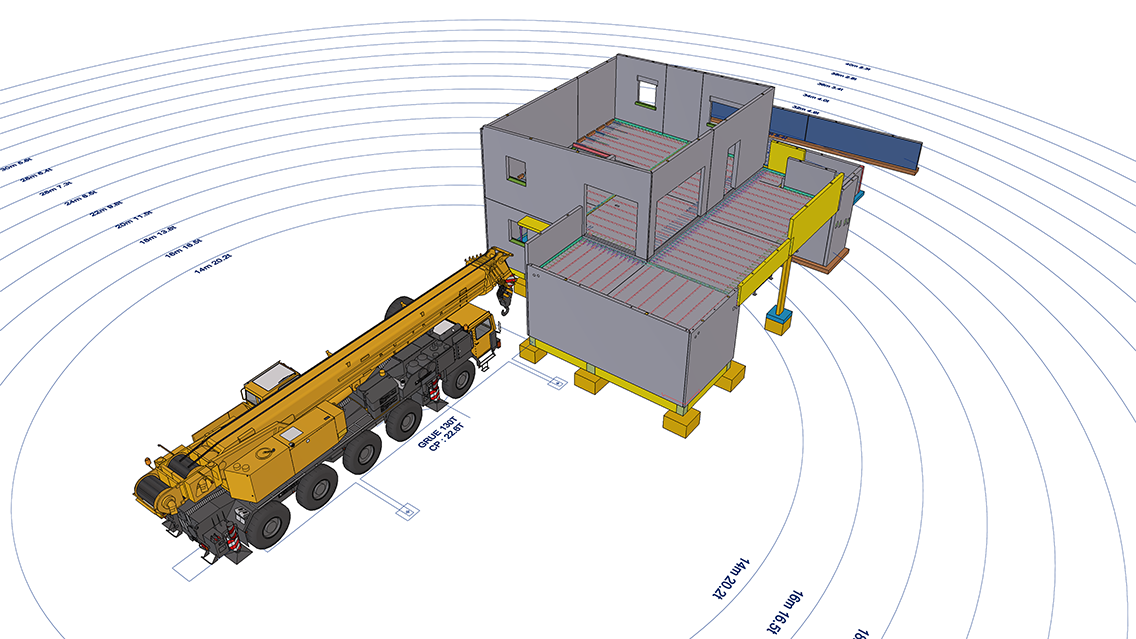

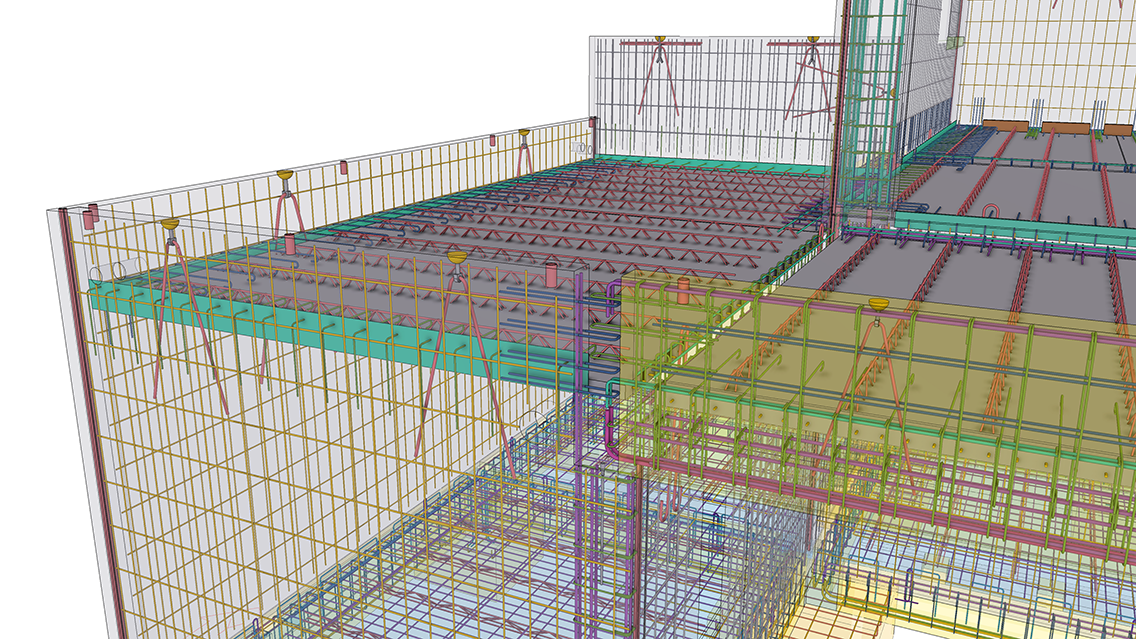

Today, we've taken Trimble's solutions a step further. We install our own pavilions using the Trimble RPT600 station and Trimble Field Link software. We are making progress in the methods aspect of our pavilions by integrating weight verification of prefabricated elements using the Tekla Crane tool, and we are creating 3D shoring for our multi-story pavilions when necessary.

All pavilions are designed by an architectural department. They use MIAO software to produce a 3D model. This is then exported and transformed into a Tekla-readable SketchUp version.

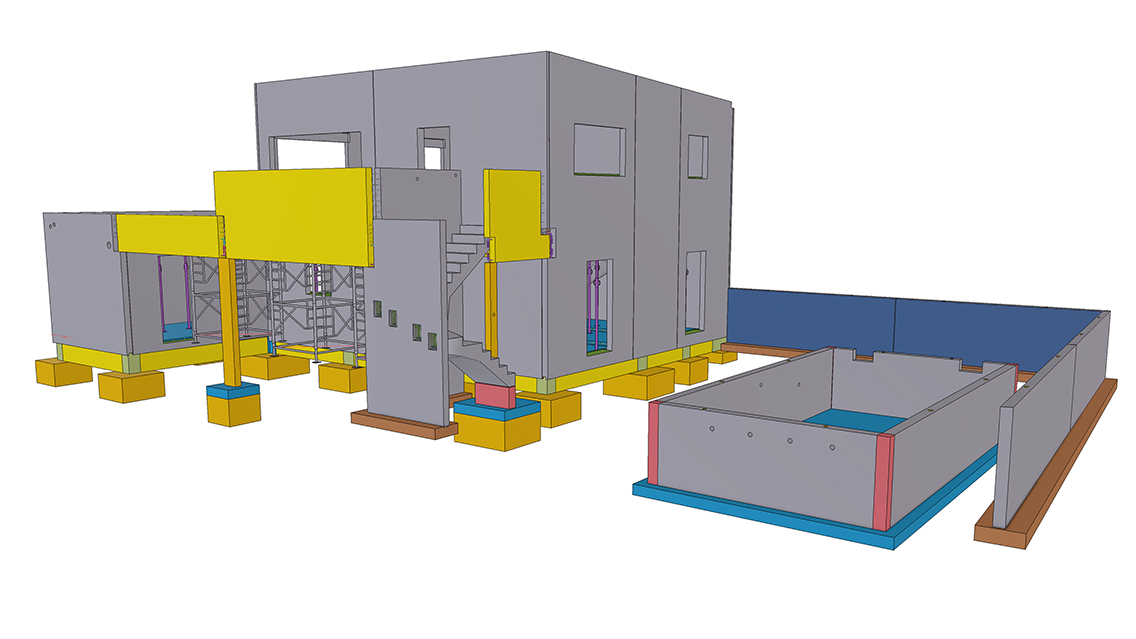

We developed a long list of customized components to optimize the overall modeling time of a pavilion. Components have been created for each type of part (insulated footings, stringers, solid slabs, columns), and Tekla component settings have been made (composite wall, crane tools, composite floor).

All our pavilion assembly teams have a tablet with the Trimble Connect application installed. This gives them access to the complete assembly file (IFC model, fabrication plans, general plans, etc.) for the pavilion in progress. This enables them to assemble the house simply by viewing the model, to improve their understanding of certain reinforcement nodes or to point out certain non-conformities.

GUILLERM's main role

Design office in the execution phase