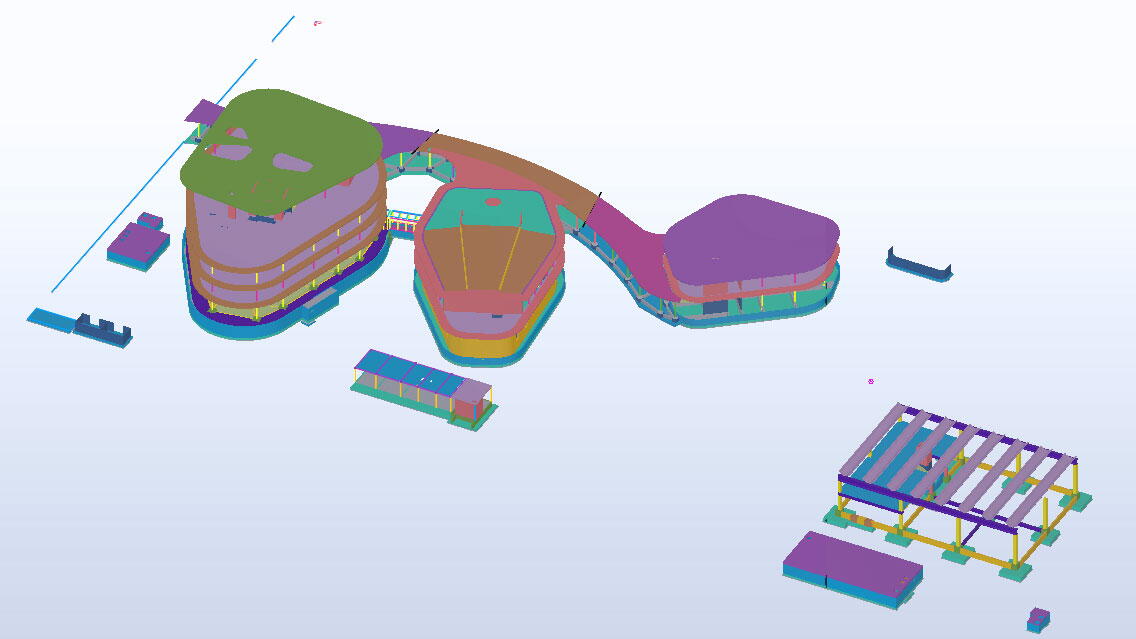

The new Coop Reno headquarter is part of a plot of about 19,000 square meters and includes the construction of six interconnected works.

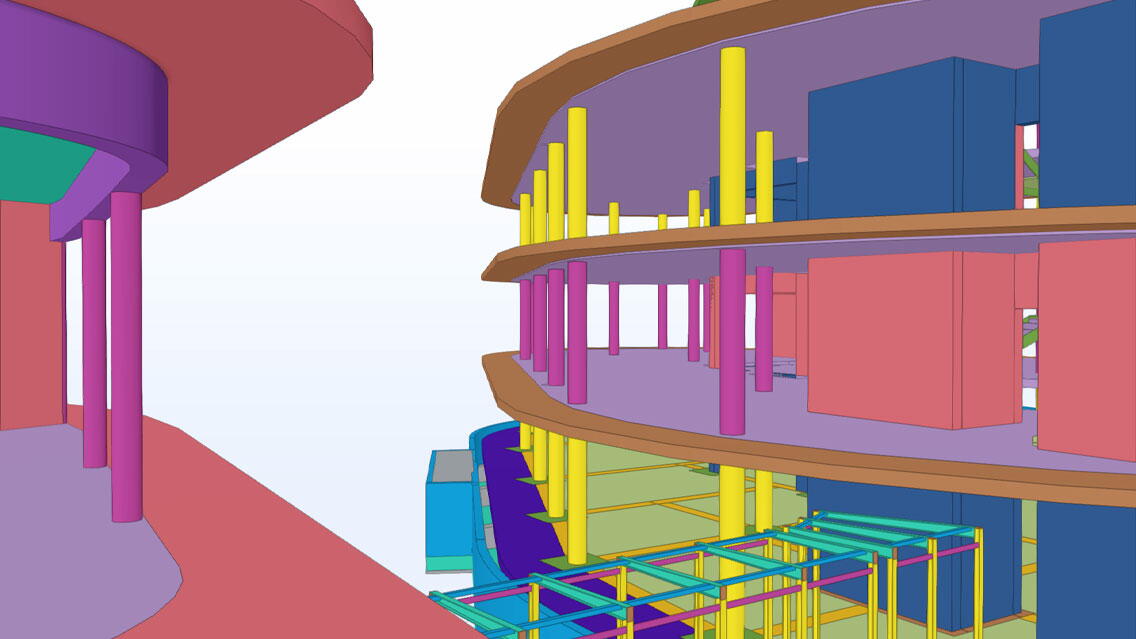

The three main buildings, Directional, Auditorium, and Multifunctional are characterized by geometries and organic shapes, made of reinforced concrete, based on ribbed stalls, and supported by circular pillars and Setti with lightened plate slabs.

In the Directional, the design choice was oriented toward the introduction of seismic insulation devices. The devices are capable of reducing the energy transmitted from the ground to the entire structure by compensating for displacements through the creation of a structural joint of 35 cm.

In the Auditorium, the large light coverage on the double volume of the hall consists of a wooden structure consisting of 20m LL beams with 26x188 section and XLAM panels.

The buildings are connected by a gallery, curvilinear and irregular in shape, which develops for about 100m, characterized by steel columns on ribbed stalls and a green roof made of a lightened plate slab.

The Warehouse, which will be made with foundation plinths cast in place for the laying of the prefabricated structure of elevation, and the Technological Building, consists of a frame in c.a. monopiano on ribbed stalls inside the fire tank made with septa in c.a.

Overall, the entire project involves the construction of over 8,000 square meters of floor space, 7,500 cubic meters of concrete and 860,000 kg of steel for reinforcements, and 42,000 kg of metal carpentry.

Advantages of using BIM

The entire project was managed using BIM AUTORING software. The software kept the client updated on the evolution of the project with access to BIM models, which constantly and gradually transformed the model into "as we can-built."

A structured participatory process created a lean and positive construction path which became the basis for achieving an integrated project for each discipline. All the structural works were developed using Tekla Structures, which enabled us to perfectly communicate with other disciplines through the IFC interchange files.

The direct and bidirectional links to the MIDAS - MODEST software ensured the correct import of the organic geometries of the floors from the early stages and helped efficiently incorporate the exact positioning of the structural elements. In addition, through the parameterization of the models, dynamic computation was performed by importing the IFC model to verify and account for the design quantities.

For design coordination and interference control, all models have been equipped with a basic design point where the respective reference IFC for each discipline has been connected. At the end of the design process, the "Digital Twin" of the intervention was realized.