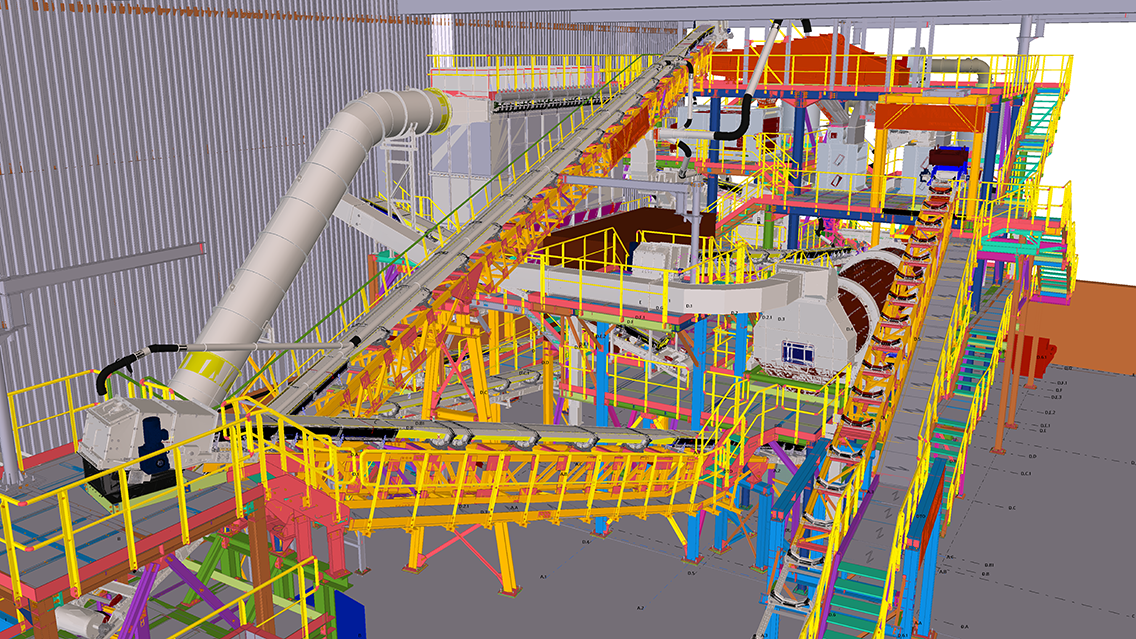

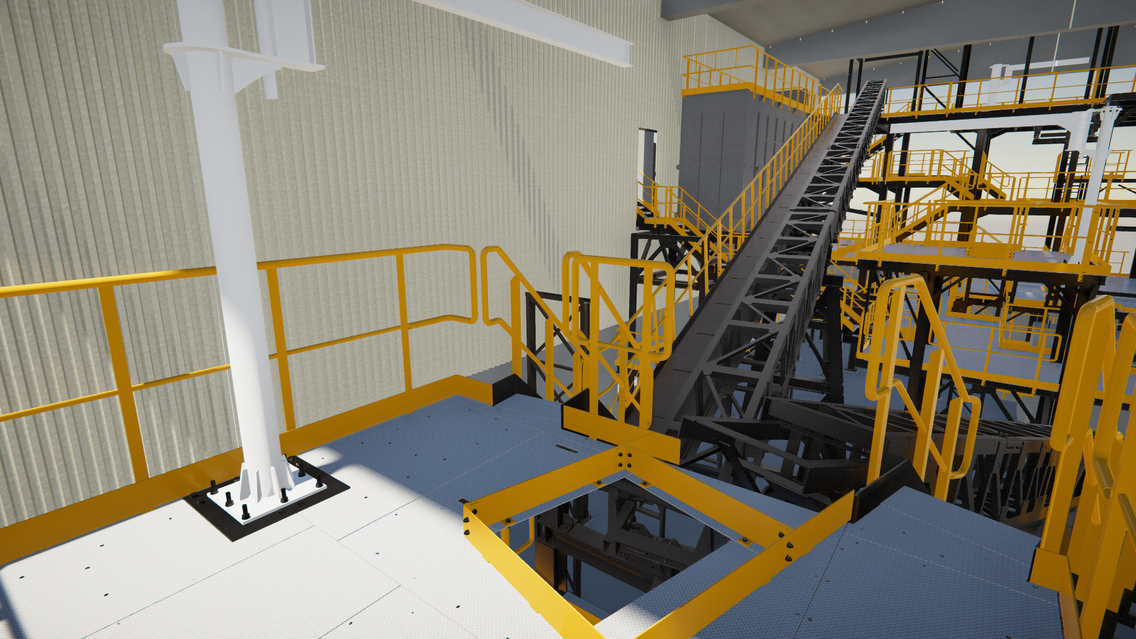

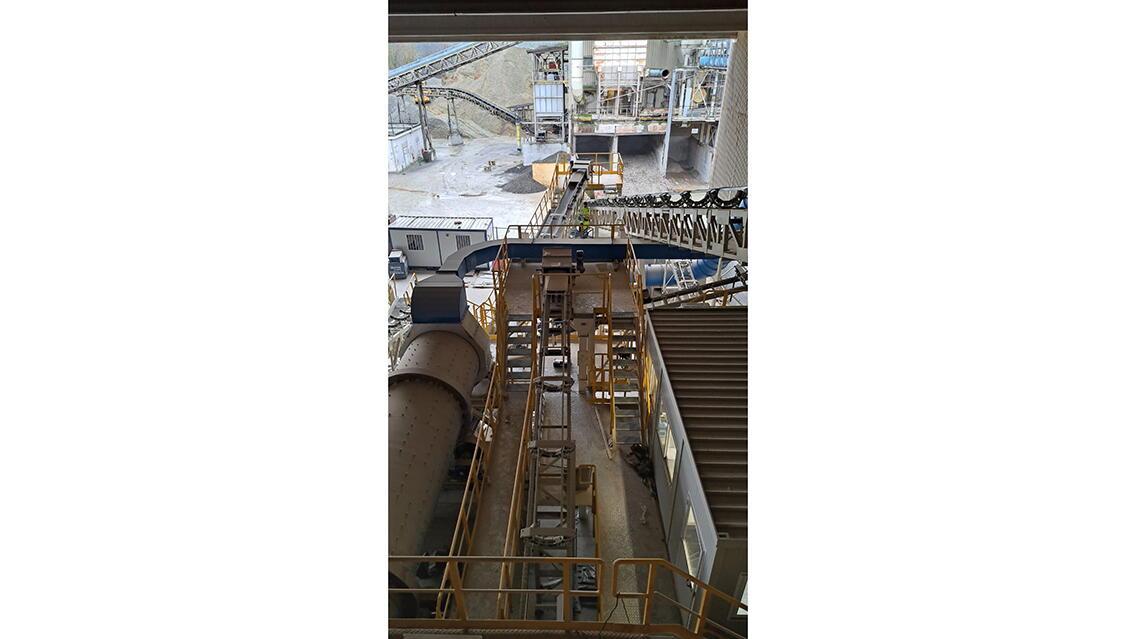

Omnikon supplies an installation for industrial drying and sorting of recycled cullets as part of the "Dry Cleaning" task. The recipient of the installation and its final user is ECOGLASS S.r.l, located in the municipality of Dego in the province of Savona (SV), Italy. The plant is built on the site of an existing plant inside a reinforced concrete structure. The existing plant was implemented in Tekla software based on 3D scans. The scope of the project includes static calculations, models and workshop documentation. The issue includes the steel structure supporting the dryer, filter, conveyor belts, feeders, fan, and pipes, as well as platforms for the operation and maintenance of the machinery. Structures for conveyor belts were designed as space trusses with a maximum span of 17.7m, divided for transport and assembly reasons into bolted modules of 5m, 5.7m, and 7m. The trusses were additionally extended with working platforms whose angles of inclination were ideally adapted to those of the conveyor belts. Thanks to BIM technology, we were able to design all steel structures to avoid collisions with the existing buildings. Single-element drawings, assembly drawings, and general arrangement drawings were created using Tekla software. The software was used to prepare material and accessory lists, which significantly shortened the design and mountage phases.