New shop in the center of the city of Kortrijk

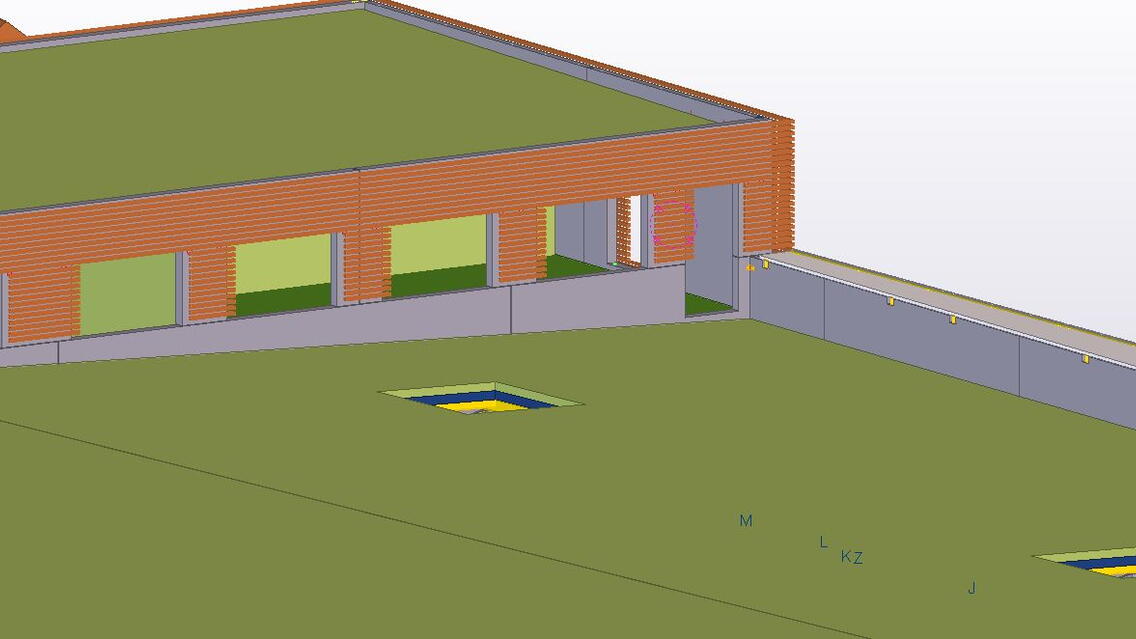

On behalf of Delhaize Group NV, Stadsbader NV built a new shop of 2500m² in the center of the city of Kortrijk.

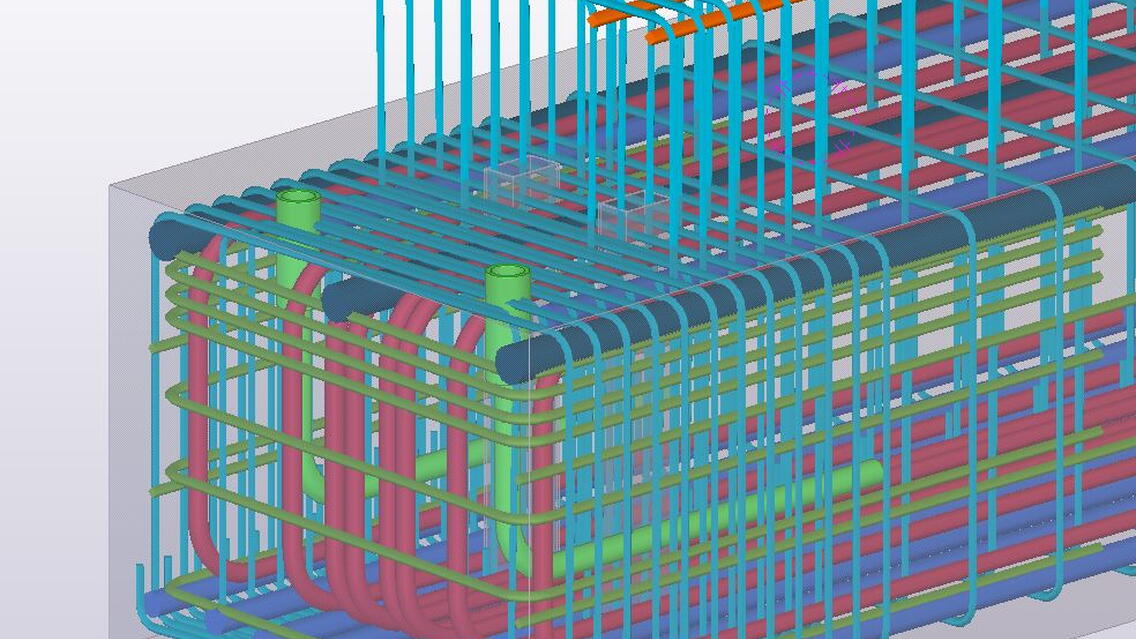

Under the shop there is a 5000m² parking lot, on 2 levels. The building excavation was made using soilmix walls. The floors of the excavation, the walls around it and the access slopes of the parking lot were made in cast-in-situ concrete. The structure of the parking lot and the shop was built with precast concrete elements (combination of column, beams and precast concrete walls). The office spaces are as if a block is floating above the shop. Here, also, we used precast concrete walls for the build-up.

Inside the shop and parking lot, it was decided to leave the concrete elements visible. The outside finishing of the building is a combination of roughcast, glass and wood.

Challenges

There were some challenges during this project. Planning was challenging because of the location in the center of the city. The space to build was limited. The shape of the building, the floating office block and the canopy above the entrance to the shop, didn’t make things easy.

What benefits utilizing BIM and Tekla software brought to the project?

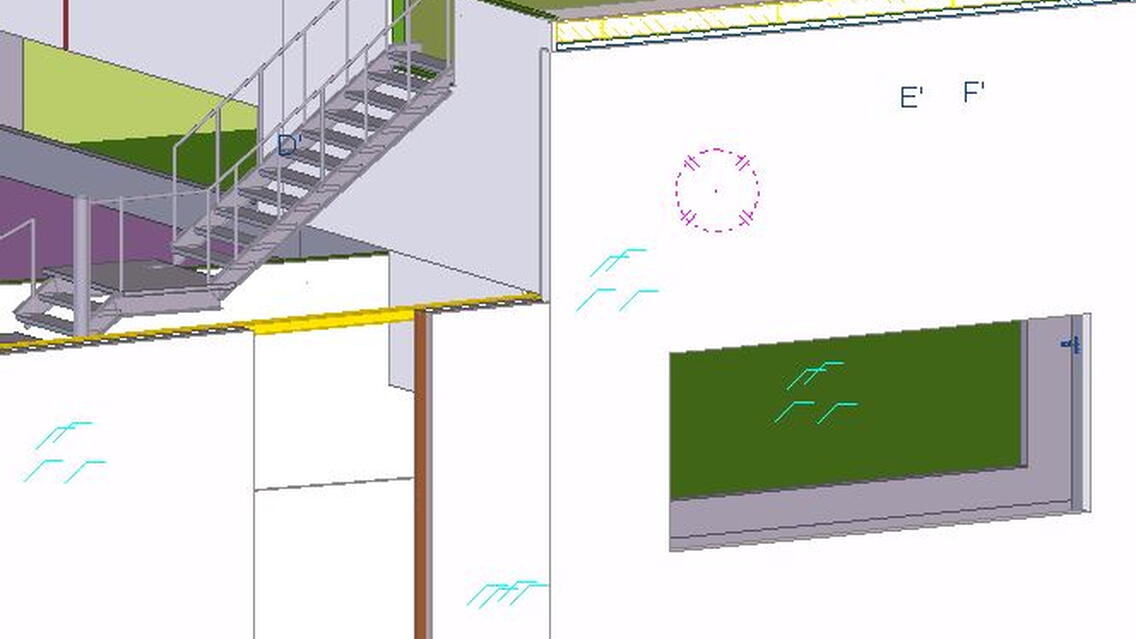

Engineering and design of the execution plans were done by Stadsbader NV. We chose a BIM-approach, due to the complexity of the project. The surrounding buildings, the soilmix walls and all cast-in-situ concrete were drawn in Tekla. The entire upper structure, including all the individual precast elements were modeled in 3D, to create the erection plans and the shop drawings. The models could be consulted on-site using Trimble Connect.

But we didn’t stop using Tekla and Trimble Connect at this point. We built 3 custom made tools for further exploitation of the 3D-model.

First, we built a tool that allowed project managers to indicate the erection sequence of the elements in Trimble Connect. They do this in the program by attaching an erection date to every precast element. This date is automatically reported in our ERP system, to have a correct production sequence as a result in our production plant Van Maercke NV. A second result: a list of delivery dates is automatically generated by doing this, to make transportation planning possible.

A second tool shows this erection sequence in a film-like way. The building is virtually built up, and this gives the people on site a guidance, to keep problems on site to a minimum.

A third tool makes the status of each precast element visual in Trimble Connect: using a certain color per status. By doing this, everyone involved in the project can see, at any date, any element of what the particular status is, and can make any necessary adjustments in the planning of the project.

The BIM approach was the right choice: the shop was officially opened on 14 May 2020.