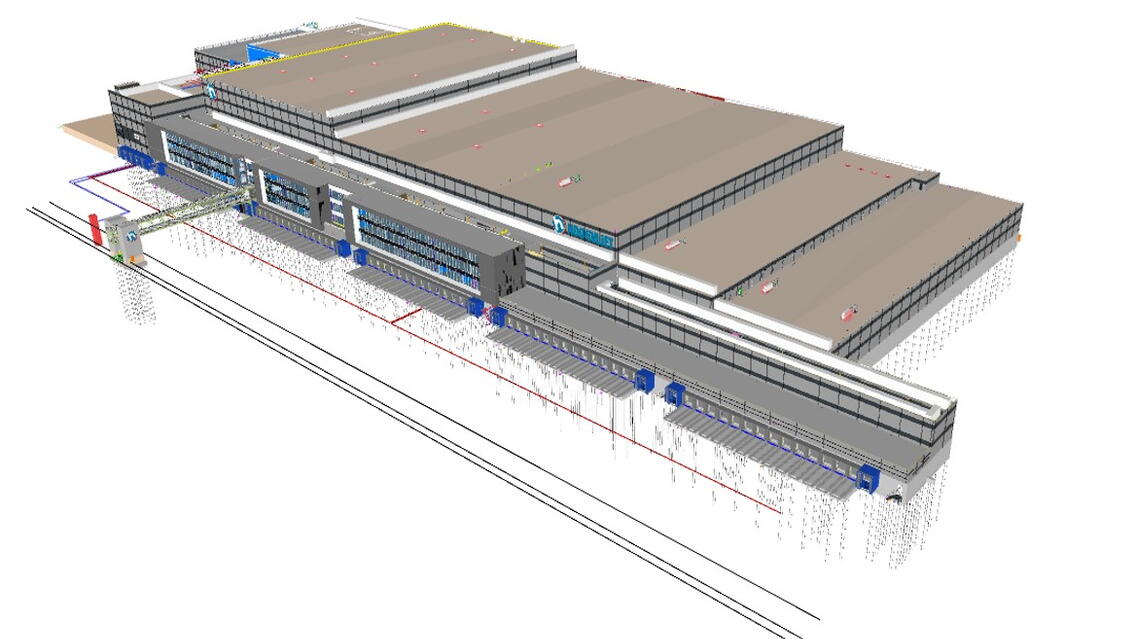

Construction of the new distribution center at the Prisma business park in Bleiswijk

At the beginning of 2018, ASK Romein Bouw was selected by Hoogvliet B.V. as the main contractor for the construction of their distribution center at the Prisma business park in Bleiswijk.

Those who regularly drive on the A12 between Gouda and The Hague can’t miss it. The new distribution center has become really eye-catching.

Ultra-modern and built with the most ambitious sustainability objective, it is unique in the Netherlands. It is a distribution center that really has everything: from cold stores to butchers, offices and a bakery. The logistical process is due to extensive mechanization and automation moreover, incredibly efficient and ultra-modern.

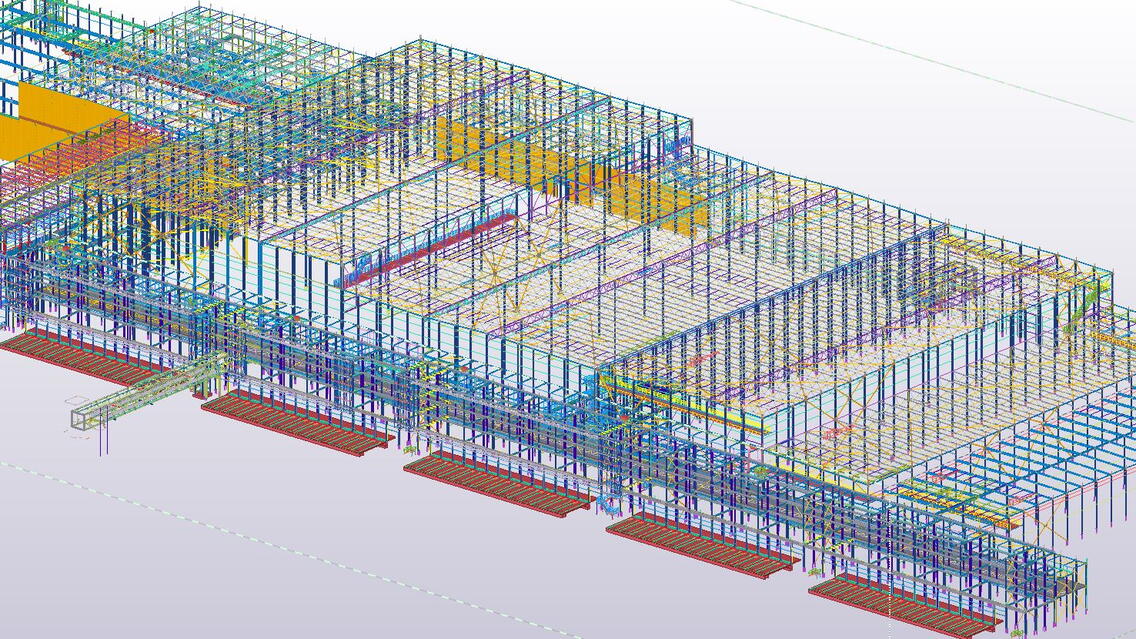

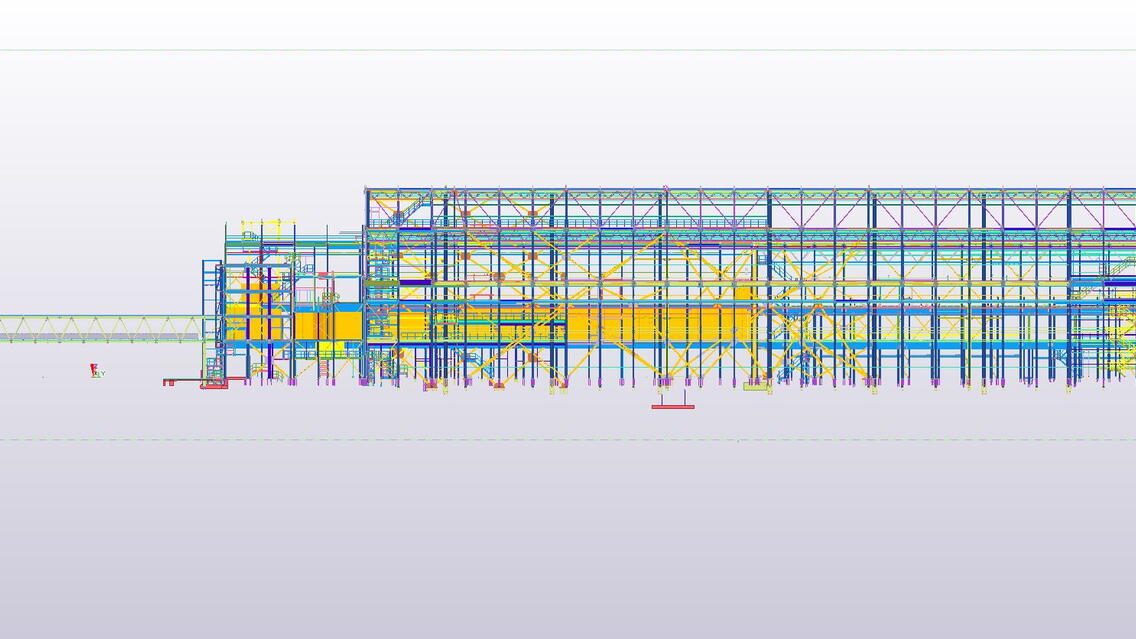

The distribution center is built using the latest techniques and has a total area of 72,000 square meters, with the possibility of expansion of another 10,000 square meters. The steel construction contains about 6,000 tons of steel in total. Environmentally conscious and energy-saving materials were used as much as possible during construction.

The building therefore complies with the BREEAM certificate Outstanding *****.

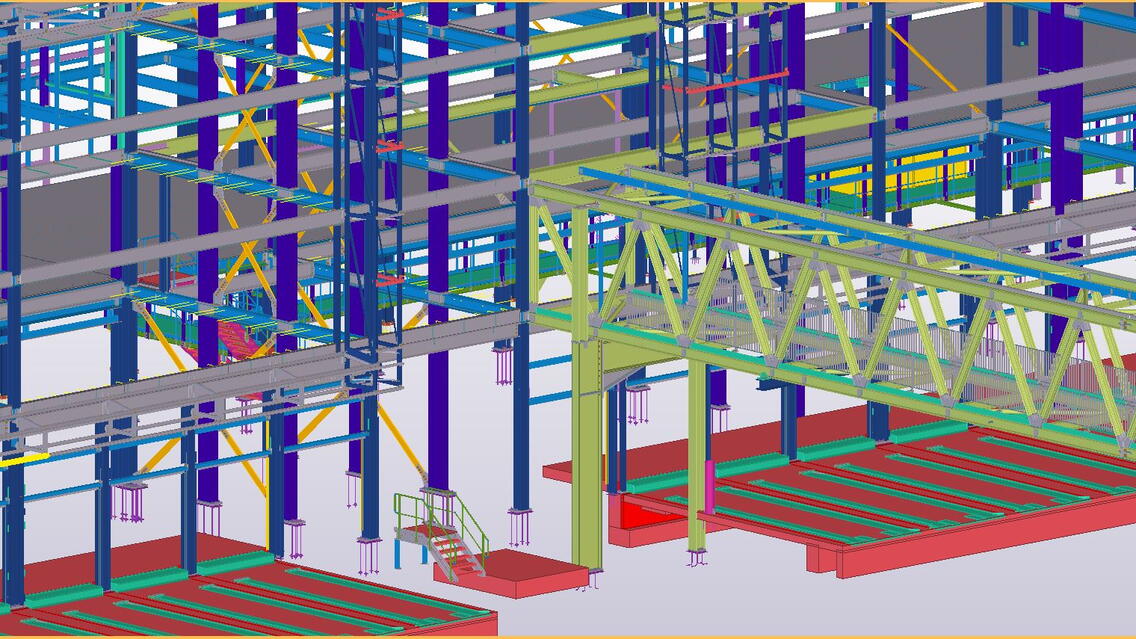

The steel construction of the distribution center is light and efficient. Furthermore, the building is equipped with energy-efficient installations and cooling techniques, heat and cold storage in the ground floors, solar panels on the roof and a greywater circuit.

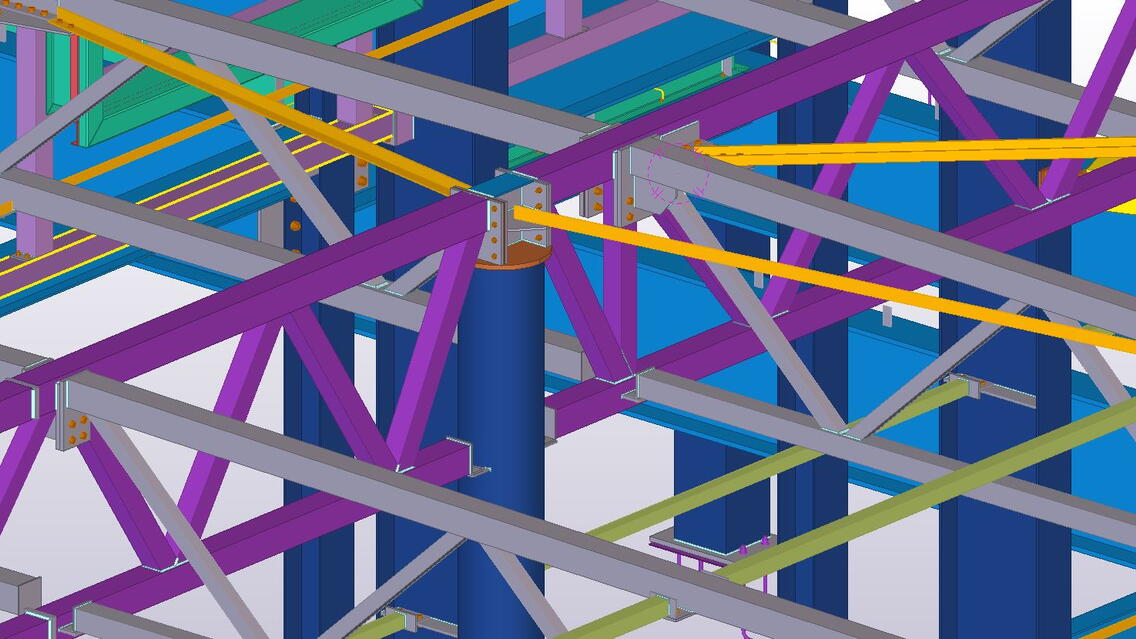

ASK Romein has produced the entire steel construction in Roosendaal. Our Beam Assembly Line has been used throughout production. This machine, developed in collaboration with Kranendonk, builds the different parts fully automatically and then welds them together directly. The ConstruSteel ERP / MRP system was also used in the production process, by which progress monitoring was also kept up to date. Using scanners, all parts were scanned when they finished a specific operation. This data was automatically entered onto the MRP system. This information was imported back into the Tekla model. This allowed us in Tekla, but also in other packages such as Trimble Connect, to make clear how far we were in the production process.

Communication and control with other construction partners was mainly via IFC exchange. The different IFC files were put in the Tekla model so that newer versions were automatically overwritten. Since more than 100 reference files were used, good organization of these files was vital. This was very easy to realize in Tekla.