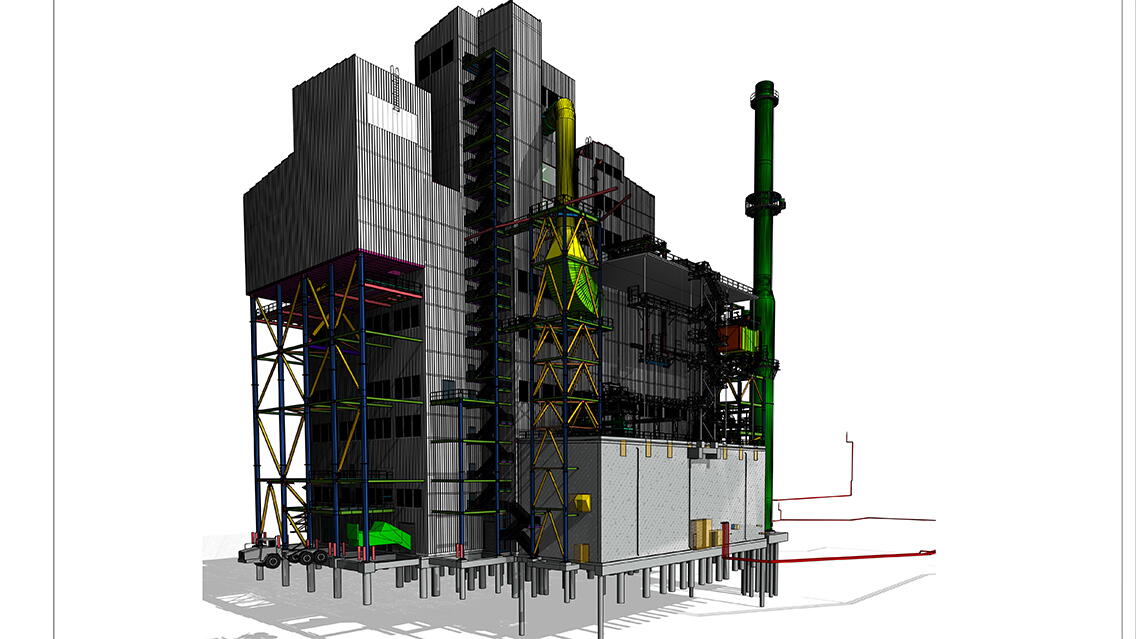

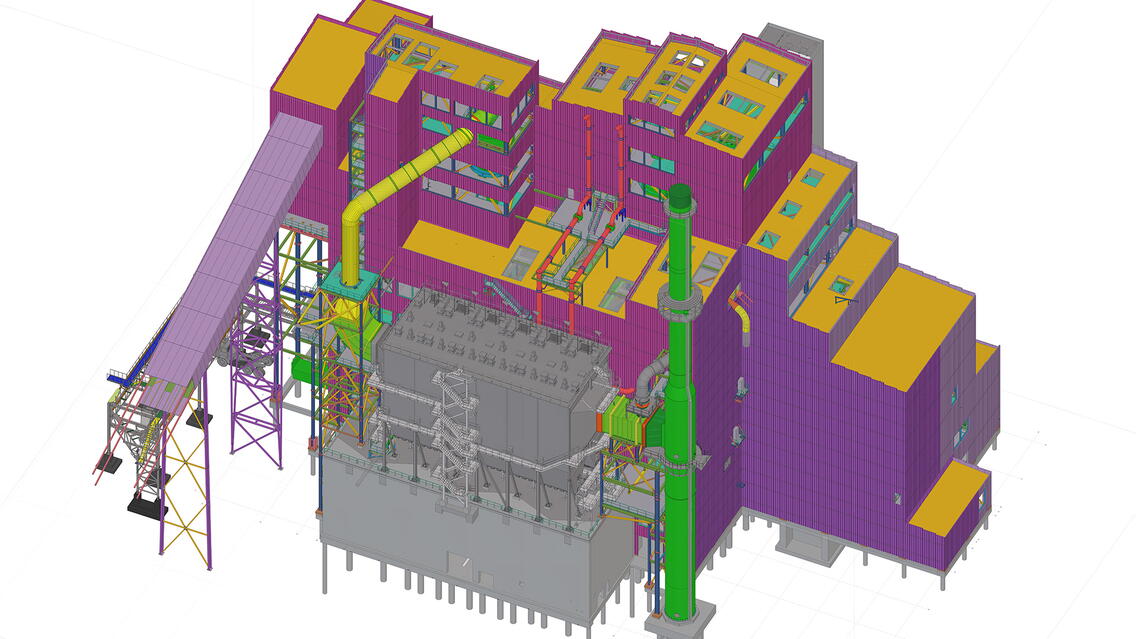

In addition to the retort building, the Enefit 280-2 oil plant complex includes a condensation area to separate the final products from the retort production and a turbine building to generate electricity from the residual heat to run the plant.

The retort building of the Enefit 280-2 oil plant is unique.

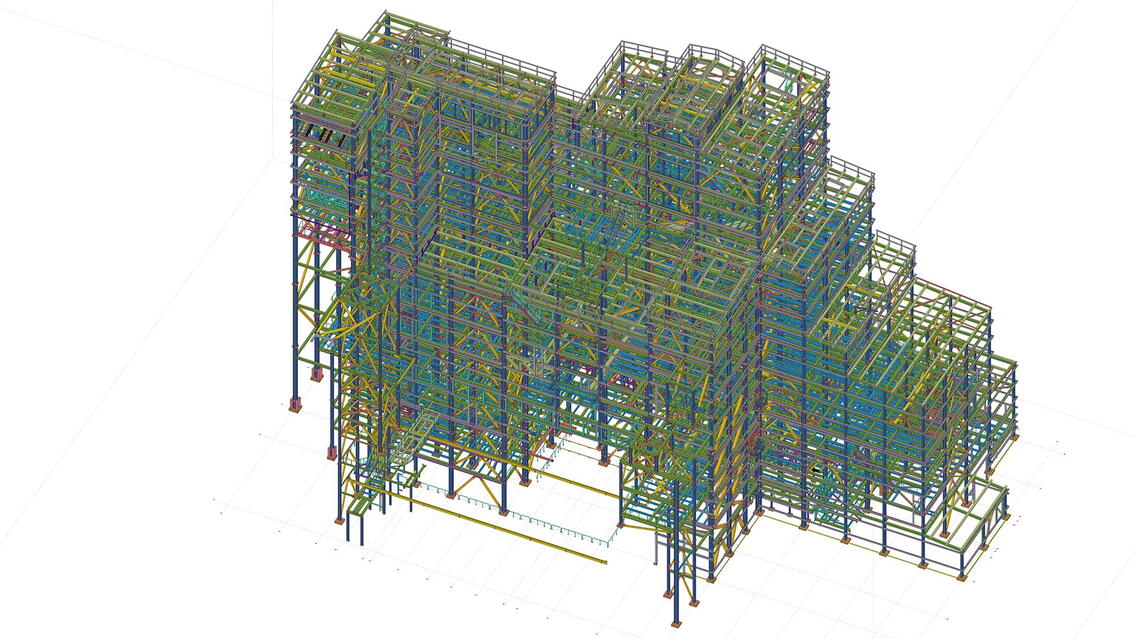

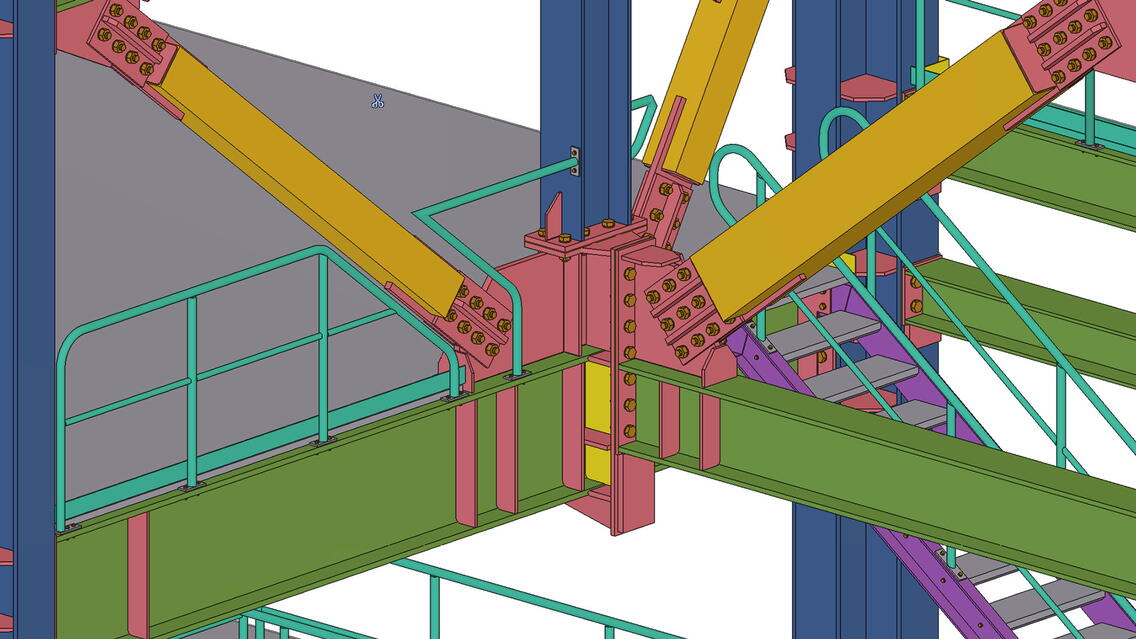

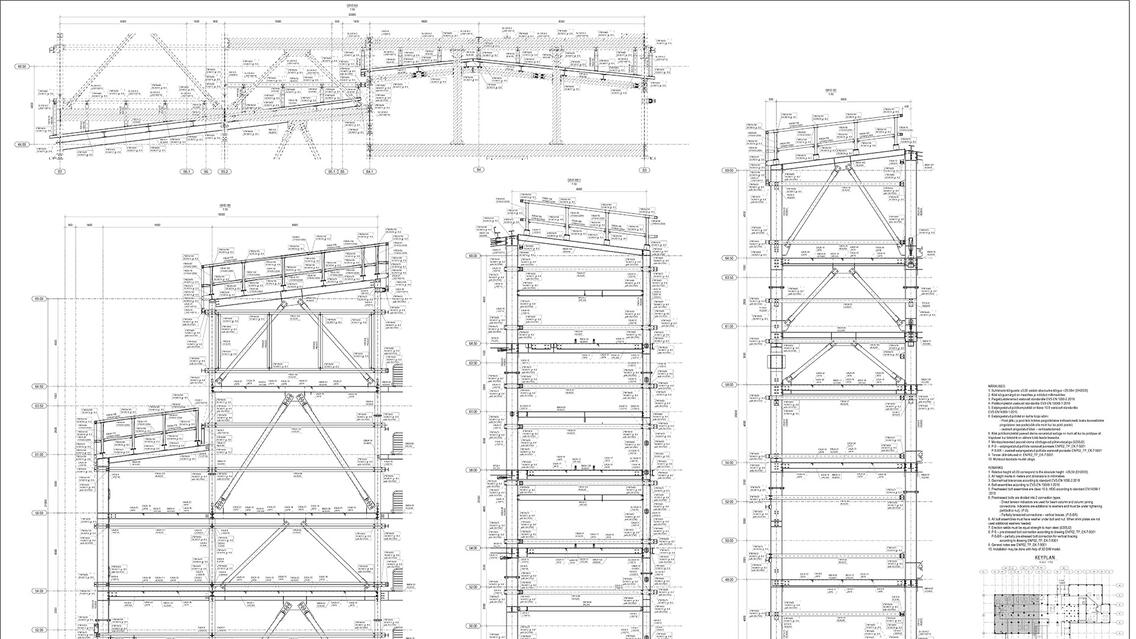

The building will be over 70m high and contain over 6,700 tons of steel structures to form the supporting frame and the production technology, together with hundreds of maintenance platforms and flat surfaces.

The entire building has been designed with the manufacturing technology and the specificities of its construction in mind. Cooperation with the general contractor (Maru Ehitus AS), the steel structure manufacturer (Maru Metall AS) and the steel and roofing assembler (Maru THM OÜ) have also played an important role in the design and planning of the solutions.

Use of BIM in design

Trimble Connect and BIMCollab applications were used to share and manage the information models in BCF format for information exchange. The solution worked as a bridge between the client's team and Norte, helping to resolve various crossovers, share design tasks within the design team, and communicate with the client.

The system was complicated because the client's design team was working predominantly in the Navisworks environment, which had models that were not compatible with the default environment. To make the solution work, an XML format file of the views of the client's models was created and, with the help of Norte OÜ's BIM manager, added to BIMCollab and, later, to BCF topics in Trimble Connect.

The drawback of this solution was that when importing the Navisworks XML file the locations of the topics in the model are lost.

Collaboration based on the BIM model/use of different solutions on-site

The data model was implemented in several different ways. The construction team used Trimble Connect's ToDo feature to share work tasks. The model was also used to coordinate assembly work and control volumes.

The integration of Maru Metalli AS' production software Strumis with Tekla enabled a current overview of the production and assembly status of steel elements. By using Tekla, the design team could see which element was in production, delivered on site or finally placed, at any time. This gave excellent flexibility to make quick and correct decisions when the need arose.

This is especially helpful for large projects where design runs parallel with production and construction, and it also saves a lot of time and money.

Innovation

Integration of Maru Metall AS' production software Strumis with Tekla, which allows direct monitoring of the production and assembly status of elements.

The process of generating data models for this project is very long. The client's designers use Aveva's E3D program, which was used to create the IFC models for Norte, and Navisworks models, which were used by Norte in the design and data modeling of the steel structures.

Trimble Connect:

The models of the structures were transferred to the data model via IFC, but the Aveva E3D/PSMS export was used by the client's designer.

Sustainability

The innovative and pervasive use of data models saved significant time in design and construction planning. It also reduced rework time and materials through early identification of technological conflicts.

Project parties:

Norte OÜ - steel structures and roofing (Tekla Structures).

Norte OÜ - main design

Kandev OÜ - design of concrete parts (Revit).

Maru Metall AS - modeling of steel structures and product drawings (Tekla Structures).

LLC Oddin (UA) - modeling and drawing (Tekla Structures)

Ingeniería Alpaca S.L. (ES) - product drawings (Tekla Structures)