The project developed by engineering and design office Simas80 concerns the structures of an energy transition plant in Africa. The plant will ensure clean energy production derived from vegetable biomass.

Simas80 took care to complete the detailed engineering of some structures for a total of about 1000 tons. Among these, the two presented here this competition are the most interesting from a structural point of view.

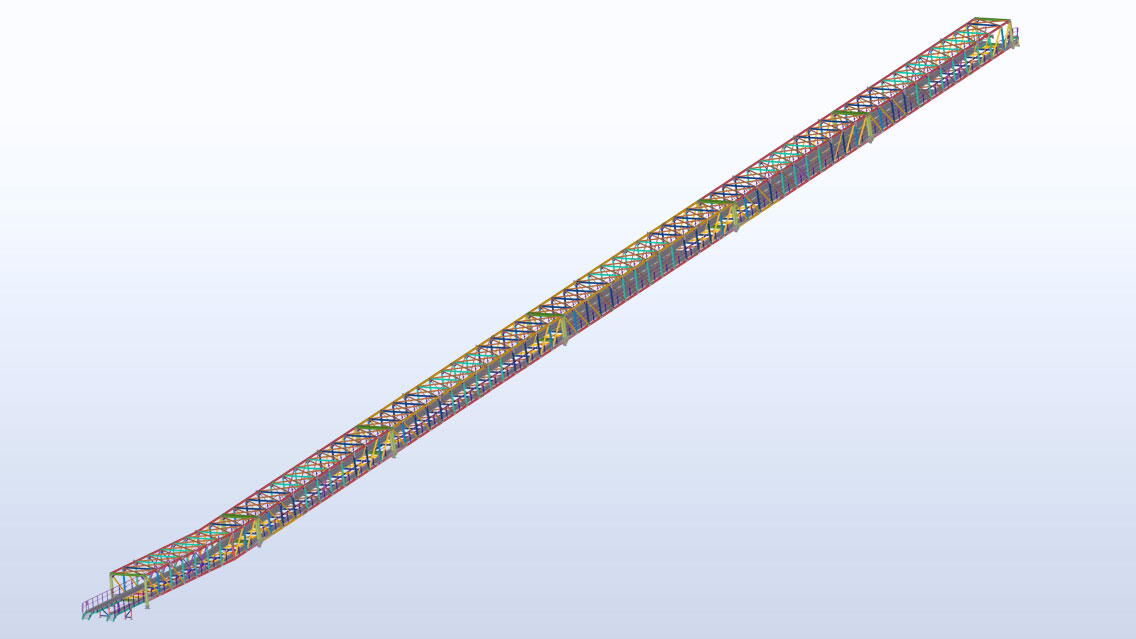

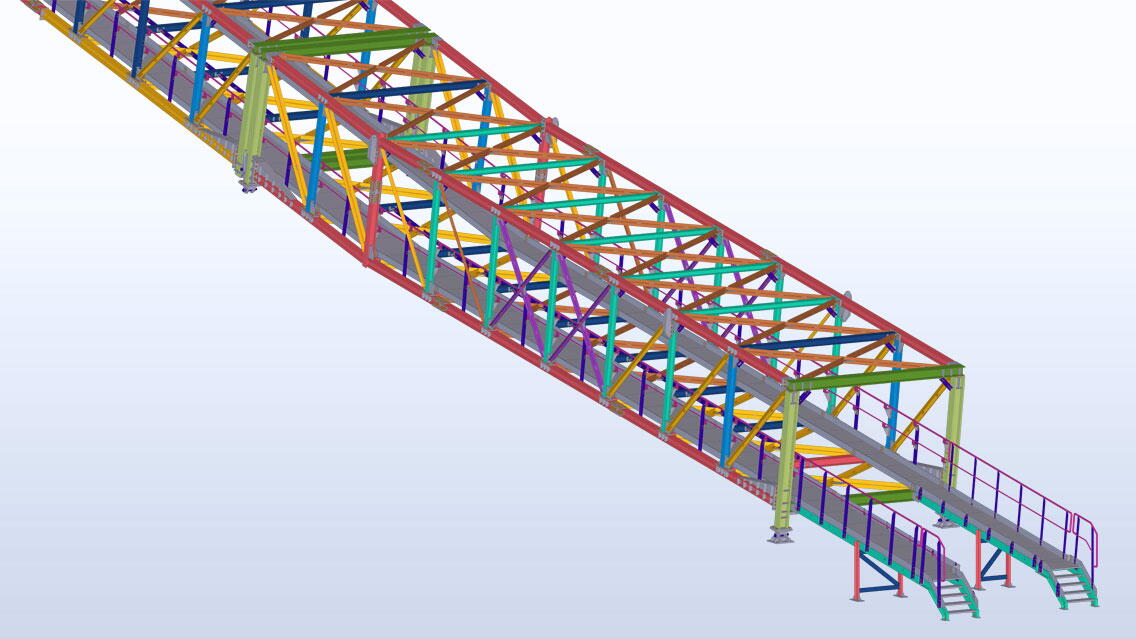

The first structure is a modular tunnel with a length of about 220 meters that supports a conveyor belt and has two walkways inside to serve the belt. The tunnel starts from the ground and reaches a height of about 55 meters.

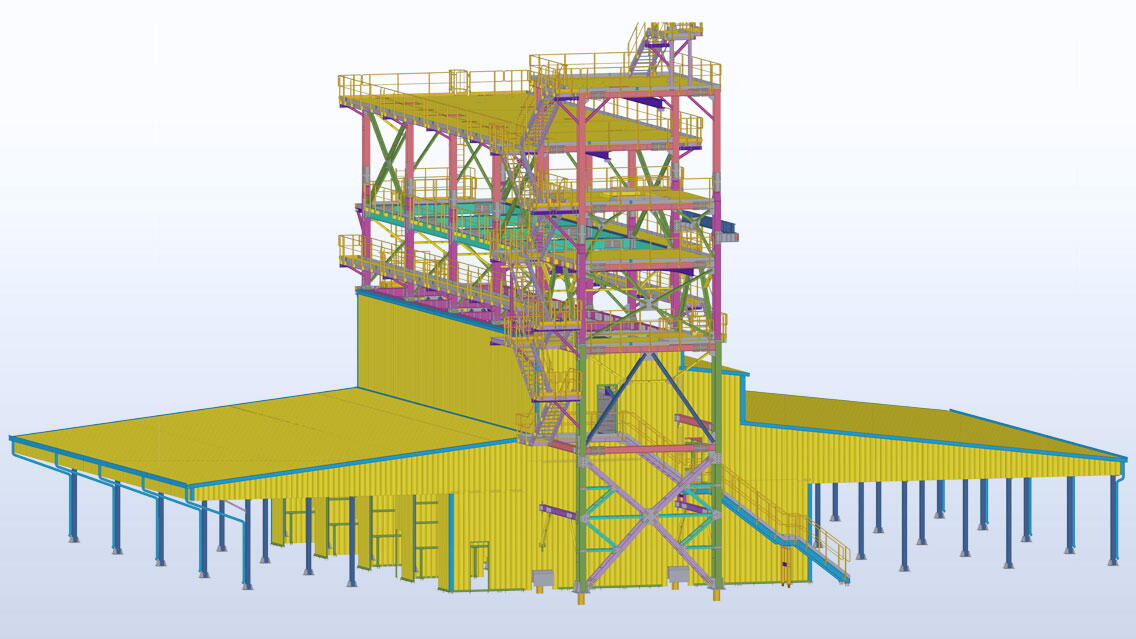

The second is a structure that allows the loading/ unloading of the material. To prevent dust from landing in random places, the load zones have been completely isolated with true infill. The structure includes an articulated barracks that was modeled after most of the main structure and built in the workshop.

In total, the structure weighs about 400 tons. The phases of the realization of a plant of this capacity have been defined meticulously to manage the priorities of our customer, manufacturer Bedeschi Spa. The careful management of priorities has allowed a production flow aligned with what was expected.

Advantages of using BIM

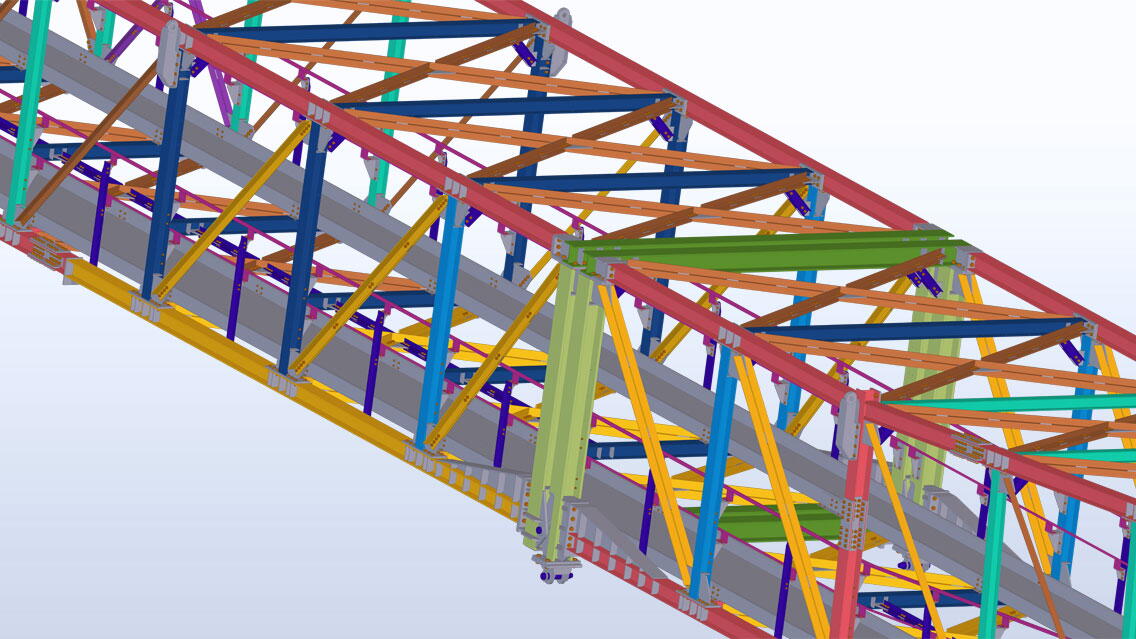

Tekla Structures was fundamental to completing such an articulated plant. In addition to metal structures, there were also conveyor belts, piping lines, filters, load silos, and many other small mechanical parts connected and not modeled with Tekla Structures.

Thanks to the possibility of geo-referencing Tekla models and importing reference objects in different formats, we could create a single model that included all the metal structures and mechanical parts with the certainty that every detail was in the proper place.

In addition, Tekla allowed us to quickly and safely make revisions to meet the manufacturer’s requirements without wasting time and enabled us to provide clear and comprehensive documentation.