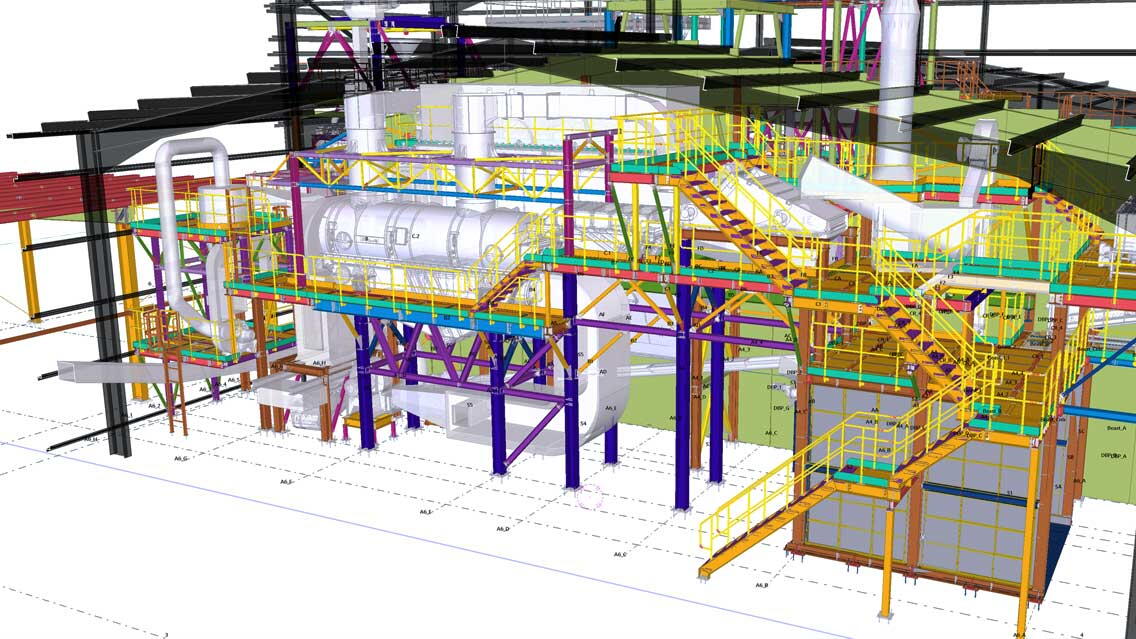

The goal was for our company to extend and improve the technological line in Dryden Aqua Factory in Scotland. Dryden Aqua is one of the largest manufacturers of glass filtration media. As marine biologists, we have a unique knowledge combination and detailed understanding of the biological as well as the physio-chemical reactions in water.

It was a huge challenge to provide our client with the complete steelwork and the new technological lines which were necessary to develop the entire process. The most challenging part of this project was adapting the new structures and maintenance platform to the existing ones. Thanks to brilliant cooperation between branches of the industry - in this case, between structural and mechanical departments - we achieved our goal.

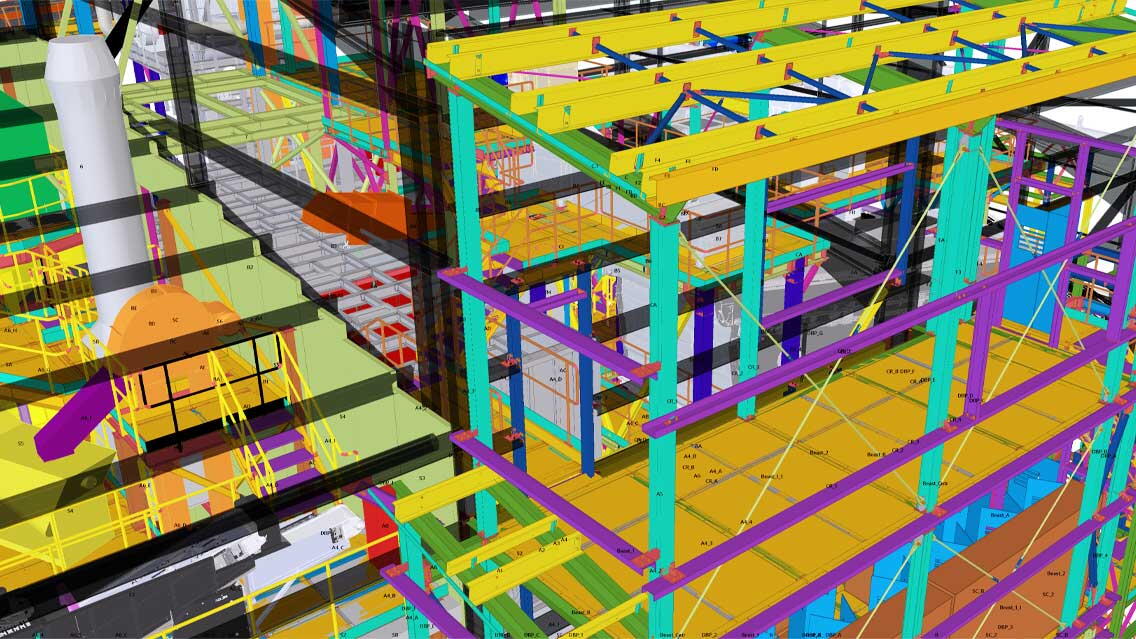

We were able to exchange models and directly implement them into our software. As a result, we avoided making collisions between the machines and the supporting steelwork at the very beginning.

After preparing and getting the confirmation for the 3D model, we could start preparing workshop documentation. Because of the size of the whole structure, we needed to divide it into parts. Every drawing was directly dedicated to a partial section and easy for the manufacturer to work with.