Project description

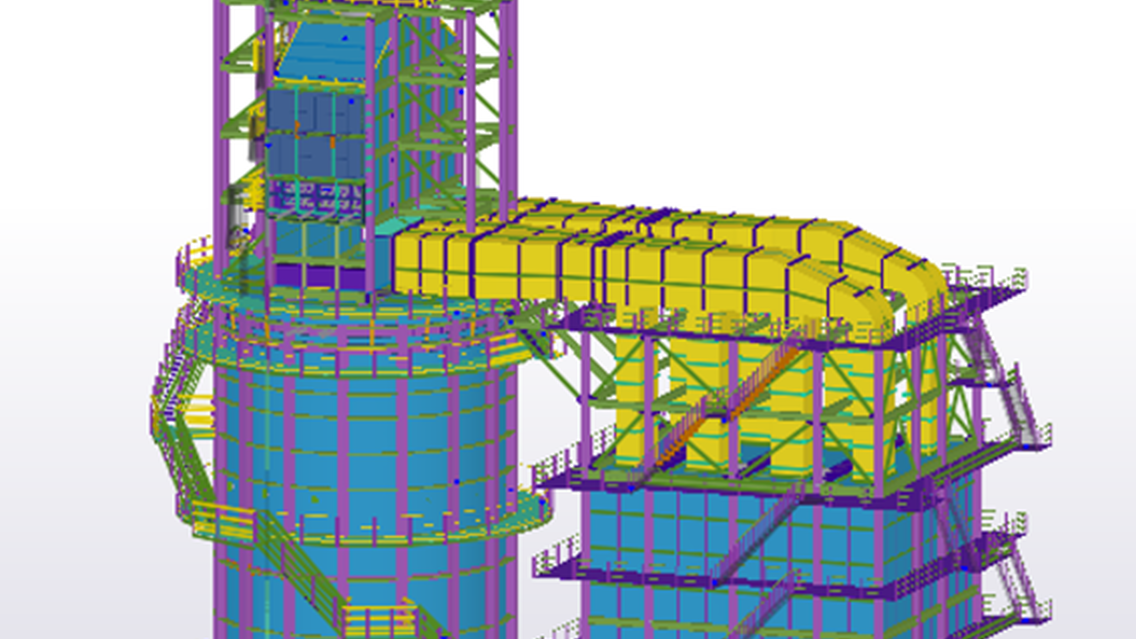

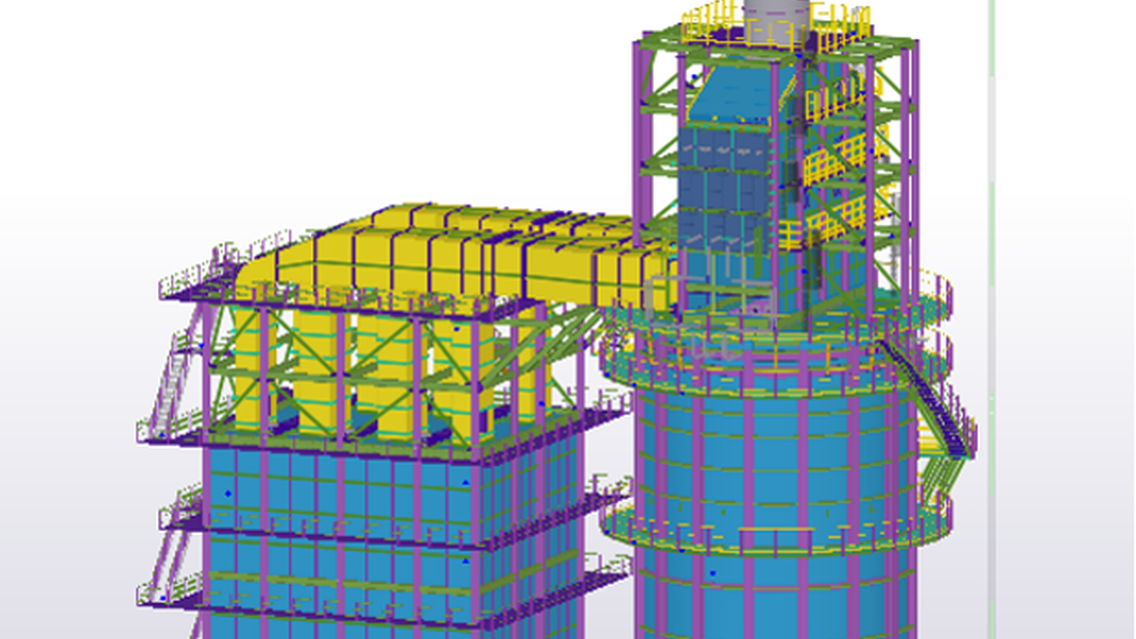

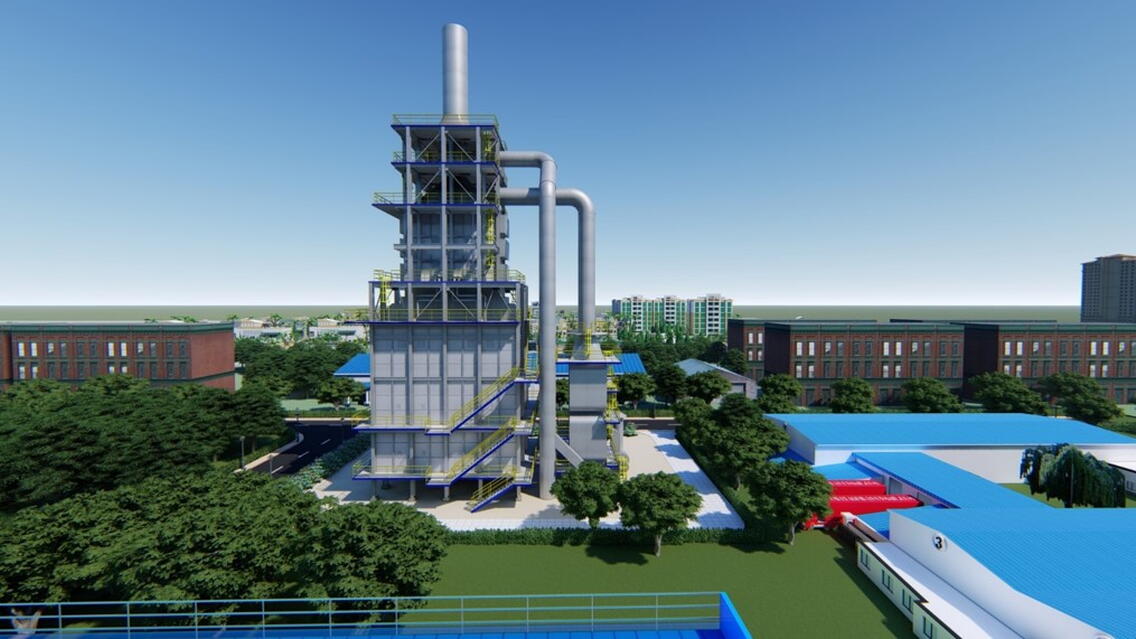

An industrial furnace is key equipment in the production process common in petrochemical plants, along with oil refining and petrochemical plant tube heating furnaces, conversion furnaces, cracking furnaces; high temperature heating, high temperature reaction of synthetic ammonia plant using coal as raw material gasification furnace or gas as raw material of one-stage conversion furnace, two-stage conversion furnace.

The characteristics of all this industrial furnace equipment mean they are relatively complicated structures, with long construction periods, strict process conditions, and high engineering quality standards.

Project Difficulties

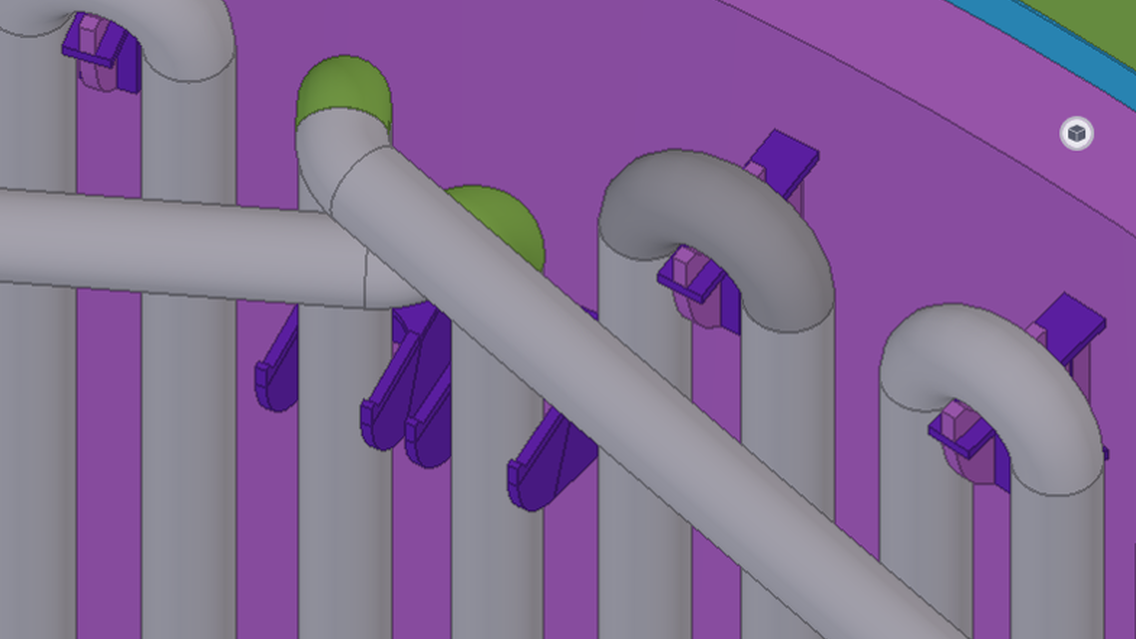

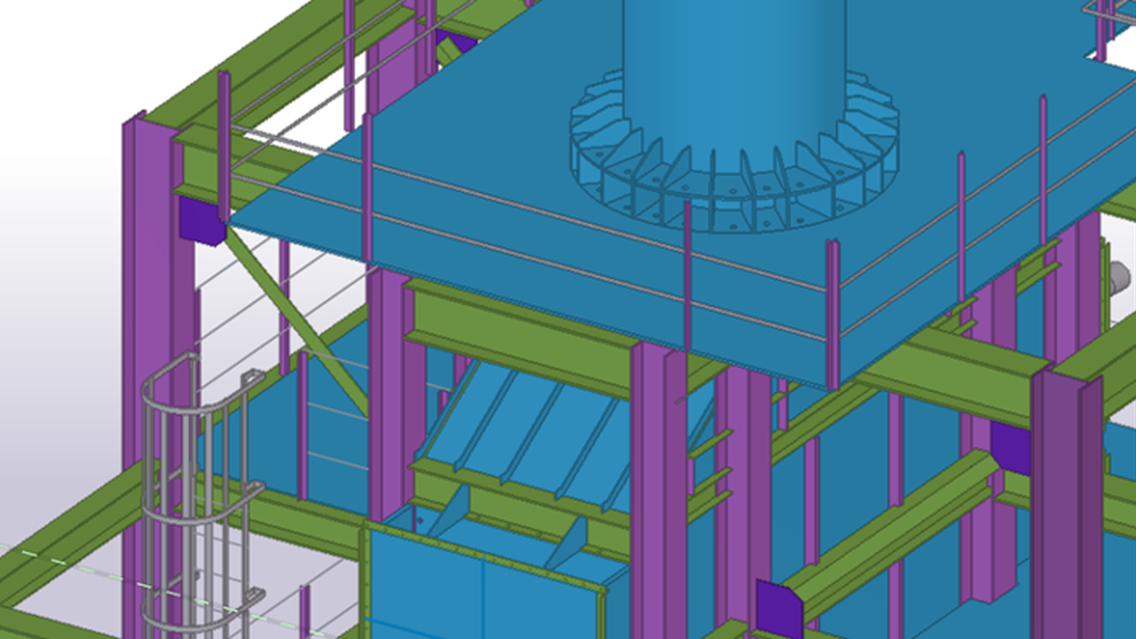

- Many model parts

- Can't be completed in a short time

- Heavy workload

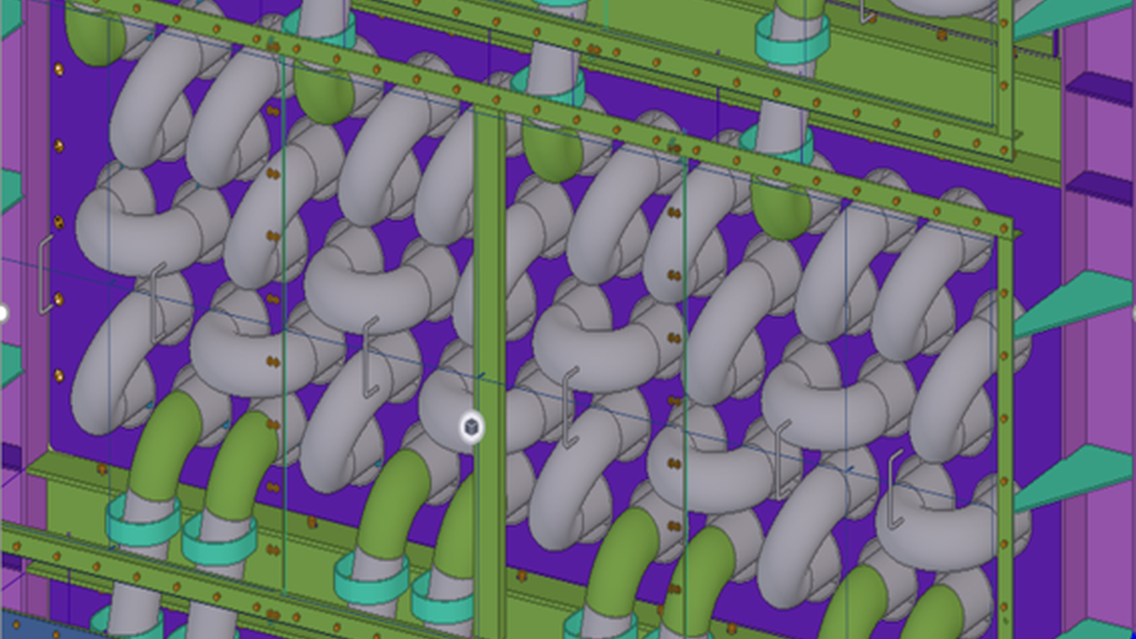

- Specially shaped pieces in the structure

Tekla application value analysis

- Improve design efficiency

- Tekla Structures can be combined with structural analysis software. In the structural design work, there is no need to redraw the structural model. It only needs to be connected in a series using the specified Link program. The structural analysis software can be used to analyze the structural model, which greatly helps the structural design work. Benefits and shorten design time.

- Batch drawing, processing and production

- Standardized components, efficient drawing, and production and processing.

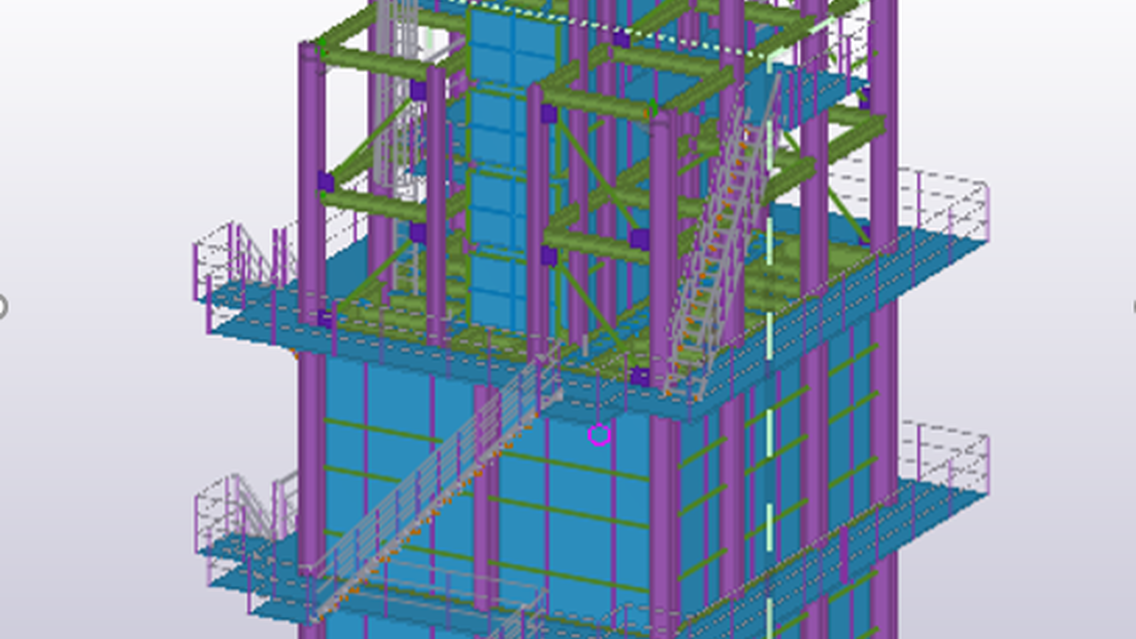

- Guide construction

- In the construction phase, the Tekla model can be better used, and the on-site installation can be completed efficiently for the end use.