Austral Construction PTY LTD (AUSTRAL) is an established General Contractor providing services to the Civil, Mining and Marine Infrastructure sectors. AUSTRAL was engaged as the Construction Contractor for this project.

3D Engineering Global PTY LTD (3DE GLOBAL) provides world class Structural Steel, Rebar, and Precast Concrete Construction Modelling and Shop Detailing Services. 3DE GLOBAL was engaged as the Construction Modeler and Owner of the Tekla Model Sharing Model.

Both the design and detailing for the project were done in the same Tekla Structures model that was shared with Owner, Designer, Contractor and Off-site Fabricator. This streamlined design, fabrication and installation works thereby avoiding costly design delays. The use of Mode Sharing also resulted in no loss of data when transferring from design to detailing, and significantly reduced the number of design drawings required because the design data was all contained within the 3D model.

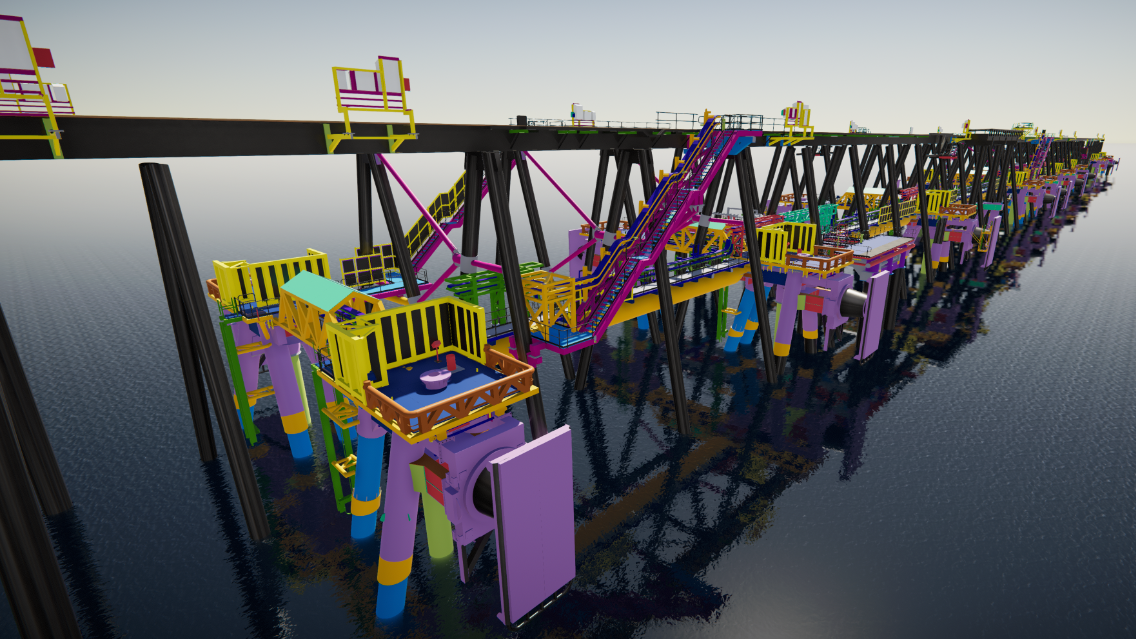

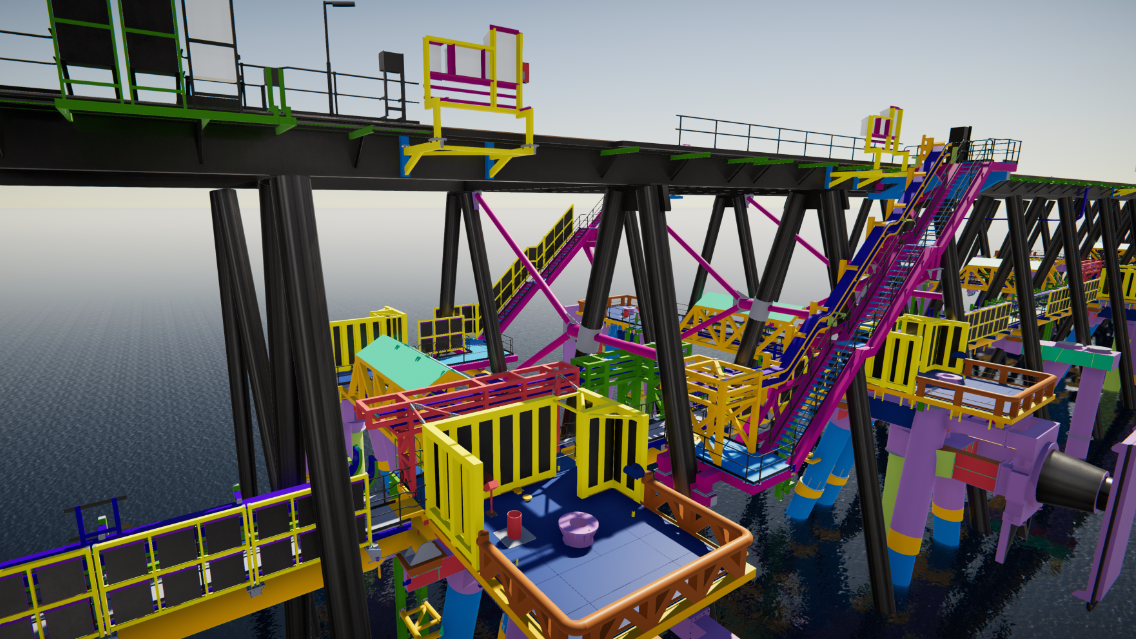

As soon as the project was awarded, AUSTRAL and 3DE Global commenced development of the LOD 300 design model into a fully collaborated LOD 400 model. This process included design optimization and constructability reviews, ensuring that the steelwork would match the certified vendor equipment that was ordered, member section size conversion, addition of temporary steelwork to facilitate construction, and ensuring that the new works in the model were in accordance with relevant Australian Standards. This process is extremely important in ensuring that the project flows smoothly through fabrication and that there is no expensive re-work required on site.

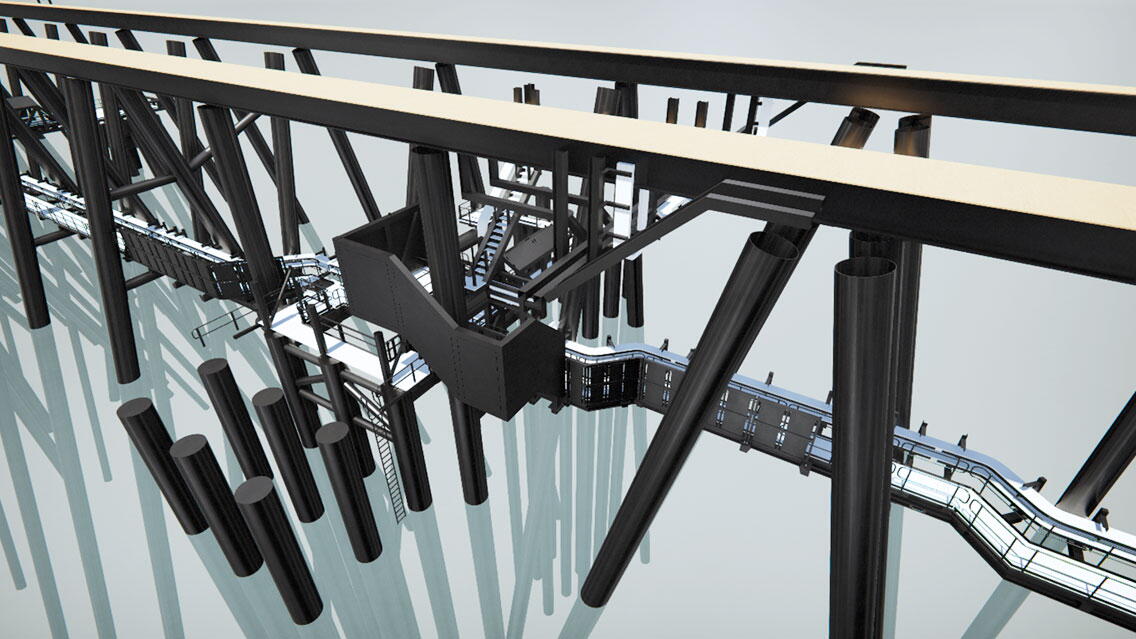

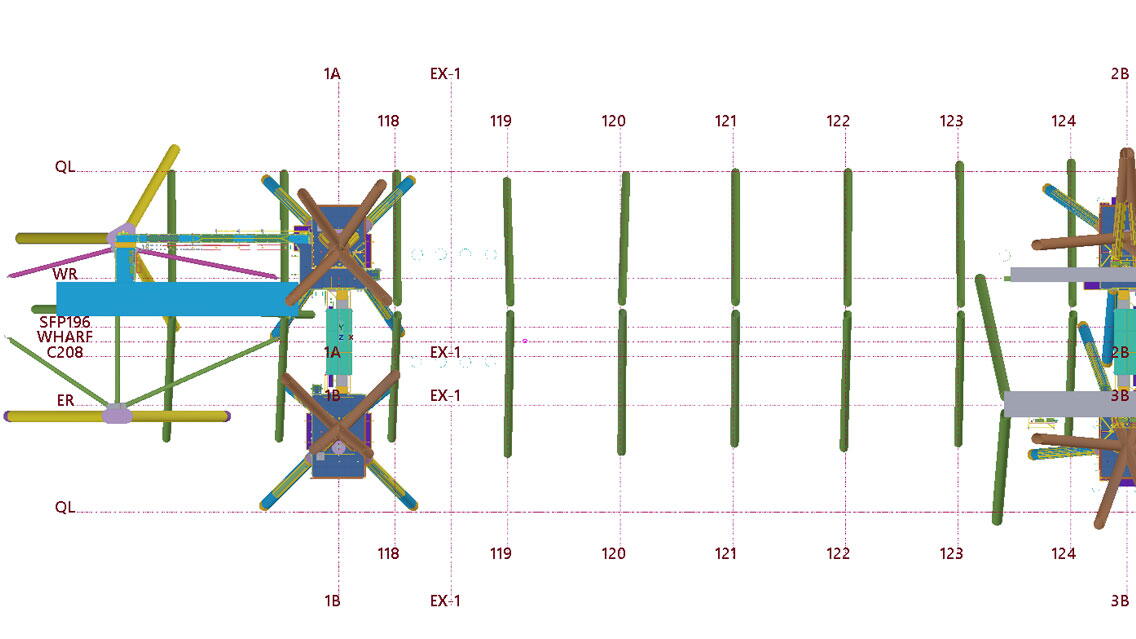

Being an upgrade to an existing Wharf, AUSTRAL engaged surveyors to conduct laser point-cloud (LiDAR) scans of the existing structure which were embedded inside the Tekla Model. This meant that they were easily accessible during the modelling stage and thereafter.

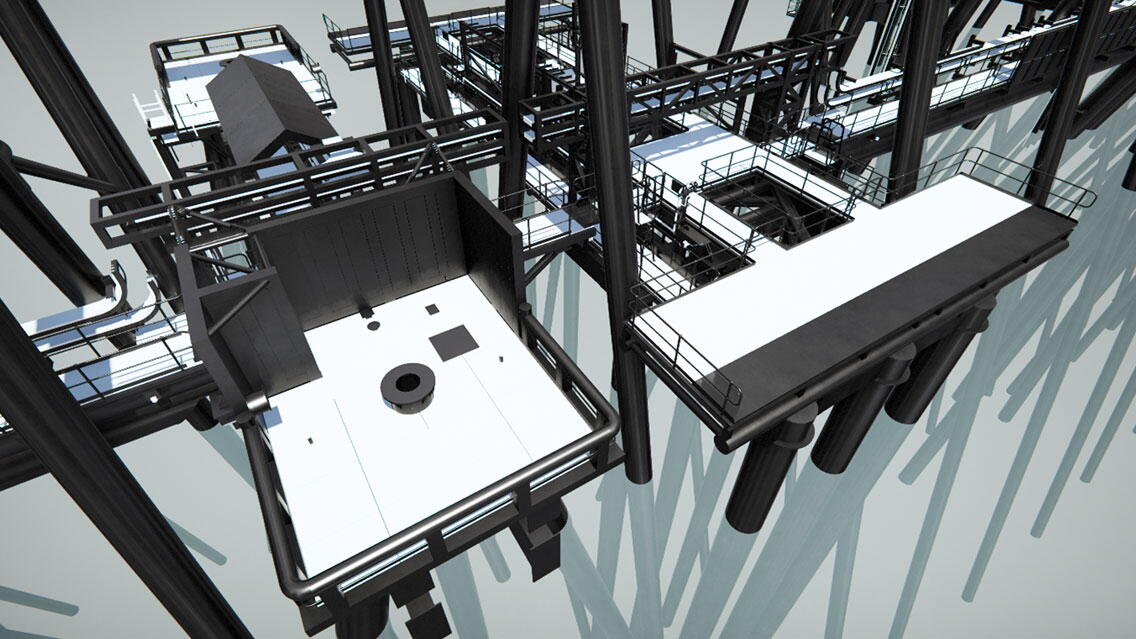

A fundamental benefit in utilizing LiDAR in conjunction with Tekla Structures modelling was borne out by enabling green field to brown field connections that “fit” without on-site fabrication modifications. The team identified the many key tie-in locations early in the model development process and incorporated multiple design changes, to fit the new structures seamlessly to existing structures that has been modified many times over the years. This modelling benefit also extended to refinement of a range of construction methodologies, from modelling pile positions for crane and pile hammer pitching checks (to ensure no clashes with existing structures and operating ship loader equipment), to constructability of landing modular dolphins, walkway and stair assemblies and Ship Access Platforms. This ultimately avoided the major design changes and delays that would have been inevitable during the on-site construction works had conventional 2D design been adopted.

For those on the project that did not have access to Tekla Structures, 3DE GLOBAL uploaded the entire model along with point-clouds and all reference models to Trimble Connect. This along with software such as TeamViewer/Microsoft Teams/Google Meet were used to share screens and collaborate quickly between different offices in different locations, depending on where the work was being carried out.

AUSTRAL engaged an offshore Fabricator for the major steel fabrication works and ensured that all shop detailing work carried out by the fabricator was done within the Shared Model. This streamlined the fabrication process and was a key factor in the project’s success as it enabled 3DE GLOBAL and AUSTRAL to monitor the progress and the quality of the detailing work as it progressed.

When it came to construction on site, the site team used their access to the Trimble Connect and/or Tekla Structures model to visualize and plan the works. The survey set-out of the steelwork was done by exporting data from the Shared Tekla Model to the Total Station survey equipment, enabling large modules to be set-out and installed with millimetre accuracy, minimising the time spent by barges and large cranes.

As-Built changes were updated in the model ensuring that the Jetty’s “Digital Twin” matched the completed project. This is of great value for the entire lifespan of the asset for both maintenance and future expansion.

It is rare for the collaborative modelling and model sharing initiatives and opportunities employed on this project to occur together. Often just one of those that were adopted in this project are implemented within the same project, mainly due to Construction Contractors doing things the way they have always done things, and sub-contractors and fabricators trying to avoid working in a shared environment unless contractually obligated to do so.

Both 3DE GLOBAL and AUSTRAL look forward to further streamlining our current processes for the benefit of all stakeholders on our future projects.

If you have any further queries do not hesitate to contact Paul Henderson from 3DE GLOBAL or Rick Pitt From AUSTRAL.

Project details

Over 3,250 tonnes of Structural Steel (prefabricated dolphin jacket structures, dolphin tops, walkways, stairs, grating, handrail, and miscellaneous smaller structures), plus approximately 3,000 tonnes of piles.

The wharf and access jetty together are approximately 3km long with the Works captured in the model extending over 600m of wharf. ALL steel is contained within the one shared model.

This project showcases the delivery of a project from design through construction to as-built, enabling asset management for its lifetime, in one cloud-based

BIM model using the following Trimble products:

1)Tekla Structures with Tekla Model Sharing

2)Trimble Connect

3)Trimble Laser Scanners