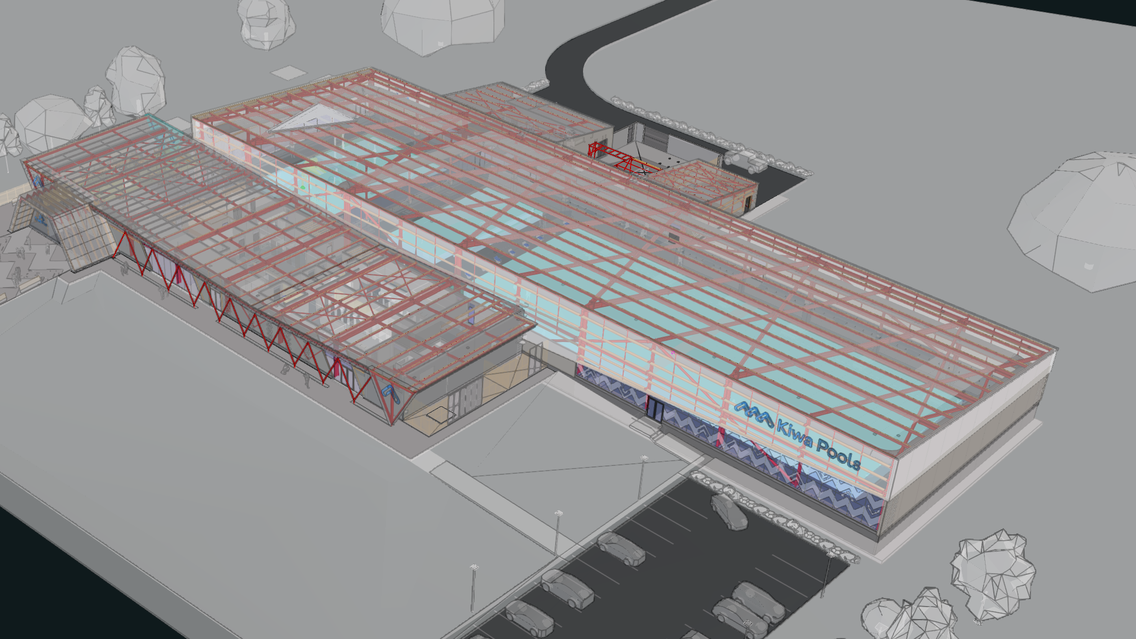

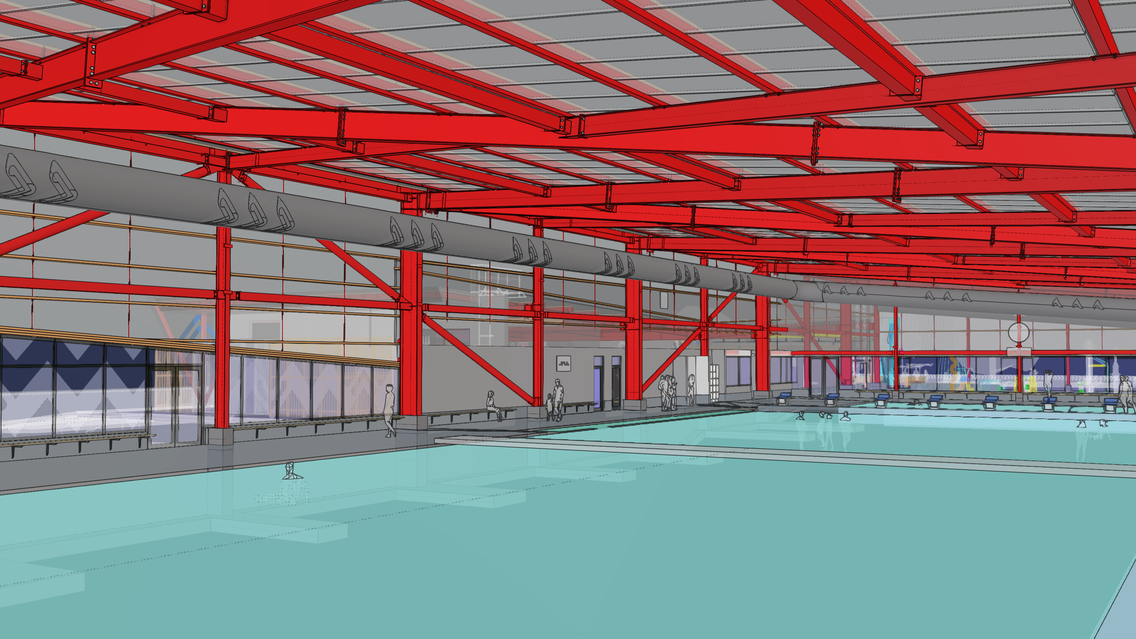

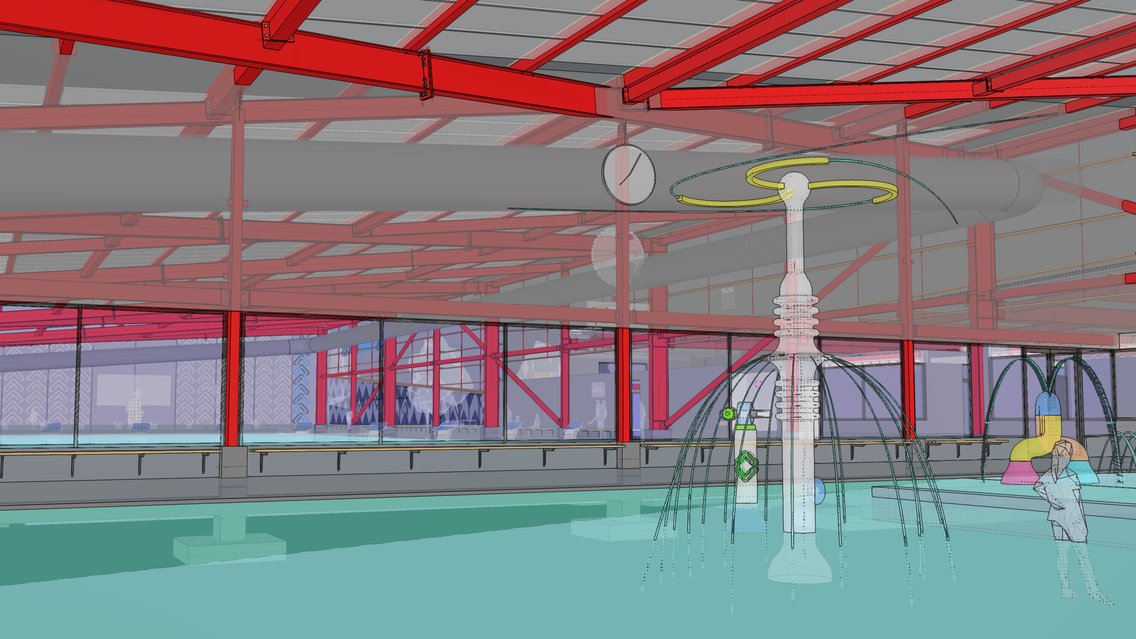

This project for Kadmon Limited stands out for its unique design and structural arrangement, featuring high-level visual steel finishes. Being a council project, it garnered significant exposure across websites, social media, and newspapers. Tekla proved to be the indispensable tool for managing the project’s complexity.

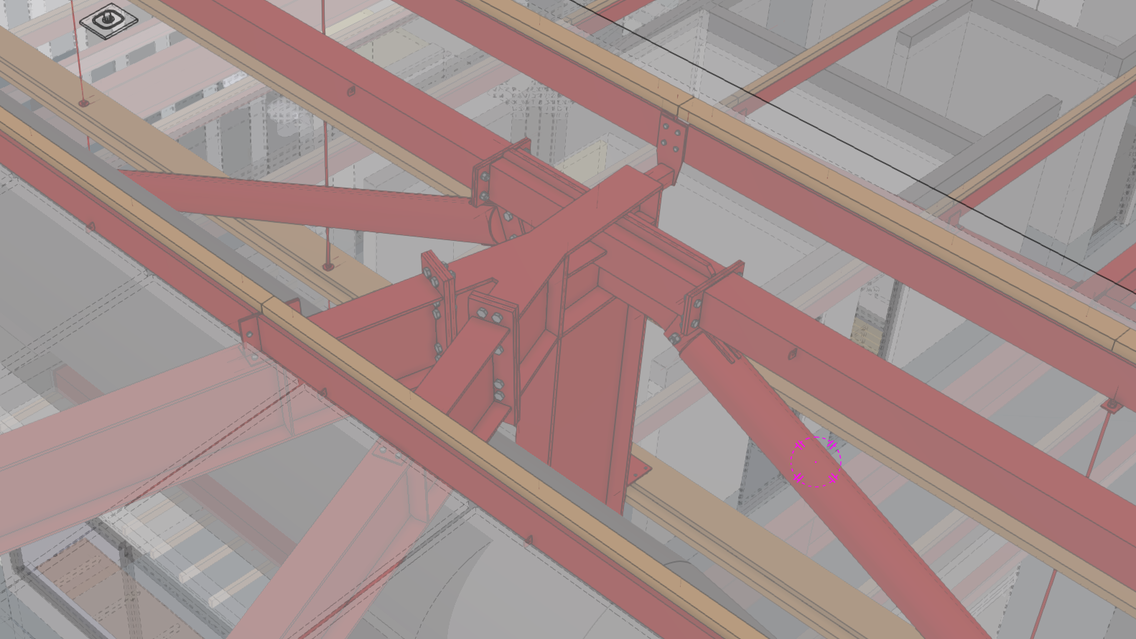

One of the most notable aspects of the project is its unconventional structure. This unconventional design demanded exceptional coordination among all trades, ensuring that steel was readily available whenever needed, eliminating the need for drilling, cutting, or grinding. Even the timber between the steel purlins and Kingspan incorporated threaded lugs at varying centers to accommodate stock lengths of timber.

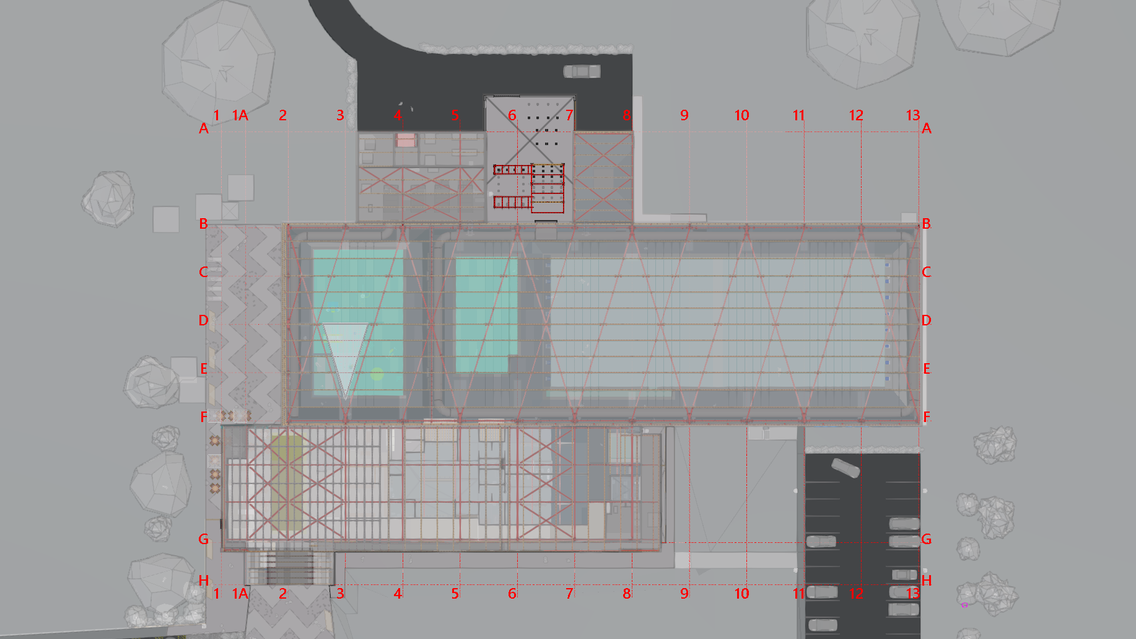

The project employed a phased running program, allowing for staged construction. While one area was under construction, the remaining areas were being refined and shop-drawn. The design team’s unwavering support played a crucial role in the project’s success.

With a budget of $46 million, the project utilised 254 tons of steel and required 2,500 drawing sheets. Coordination extended to even the smallest details, such as the cleats that support the AC ducting and equipment. Cleats and holes were meticulously designed to accommodate all timber components, aiming to eliminate any on-site drilling, cutting, or welding, especially considering the exposed steel in a wet and corrosive environment. Close collaboration with LVL timber designers and manufacturers ensured perfect alignment between steel and timber components on-site.