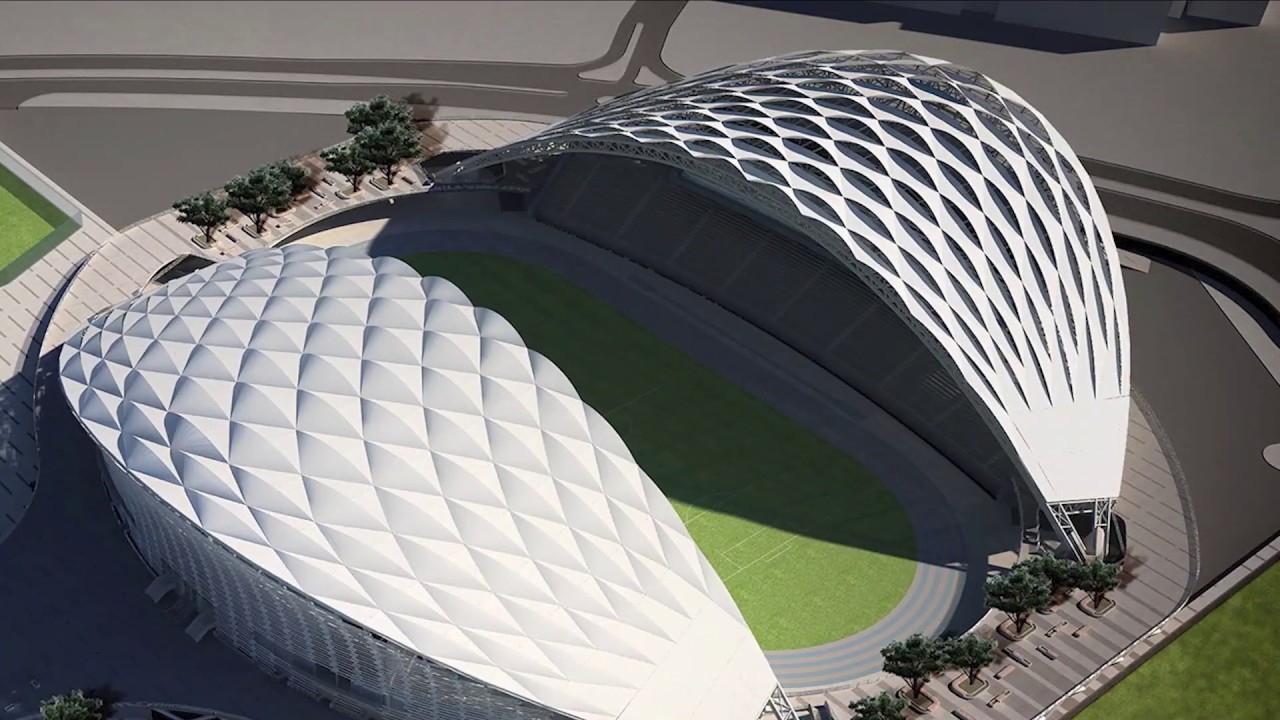

Track & Field Stadium in Kuwait

Eversendai Construction W.L.L, Kuwait was awarded the Track & Field Stadium Steelwork Package of Building-G in Kuwait University Project.

The total Tonnage of Steelwork in this Project is 8451MT. This project is located in Sabah Al Salem University City in Kuwait.

The scope of Eversendai was to provide Connection Design, Shop Drawings, BIM Implementation & Coordination, Erection Engineering Study & Stage Analysis, 3D Modelling, Workshop Fabrication Drawings, Supply, Fabrication, Composite Floor Decking, and Erection of Structural Steel Works. All the Design, Engineering & Detailing scope of works was completely taken care of In-House Engineering Department of Eversendai Dubai Office and successfully completed in line within the project schedules.

The Owner of the Project is Kuwait University, Construction Manager is Turner Projacs, Architect & Structural Engineer is Skidmore, Owings & Merrill LLP/ Gulf Consult & Main Contractor is SEG-Emaar JV.

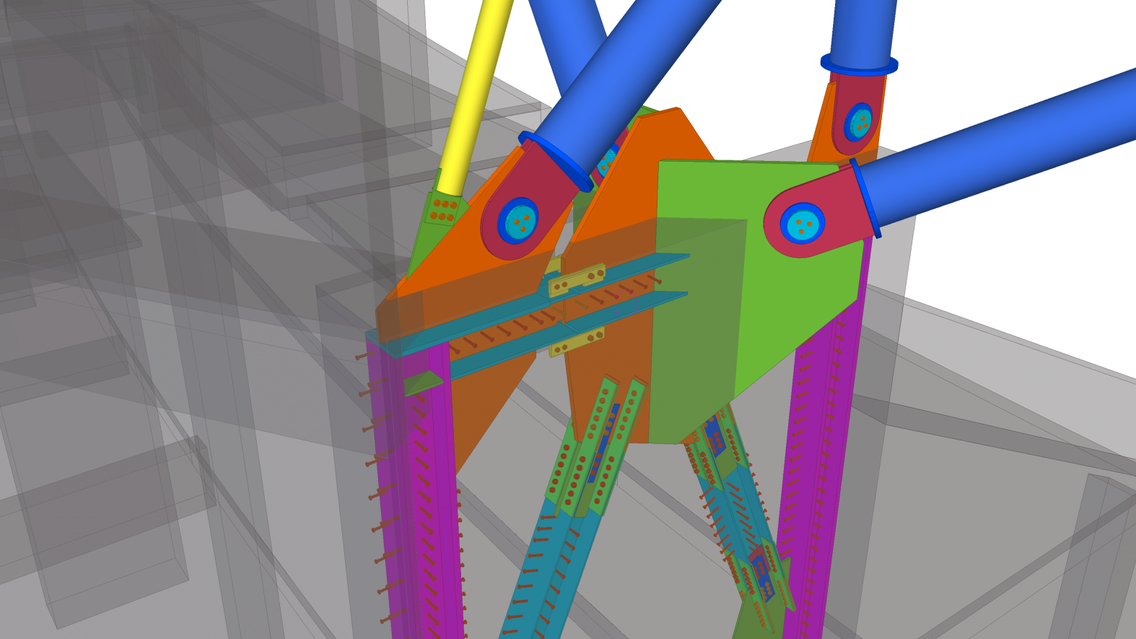

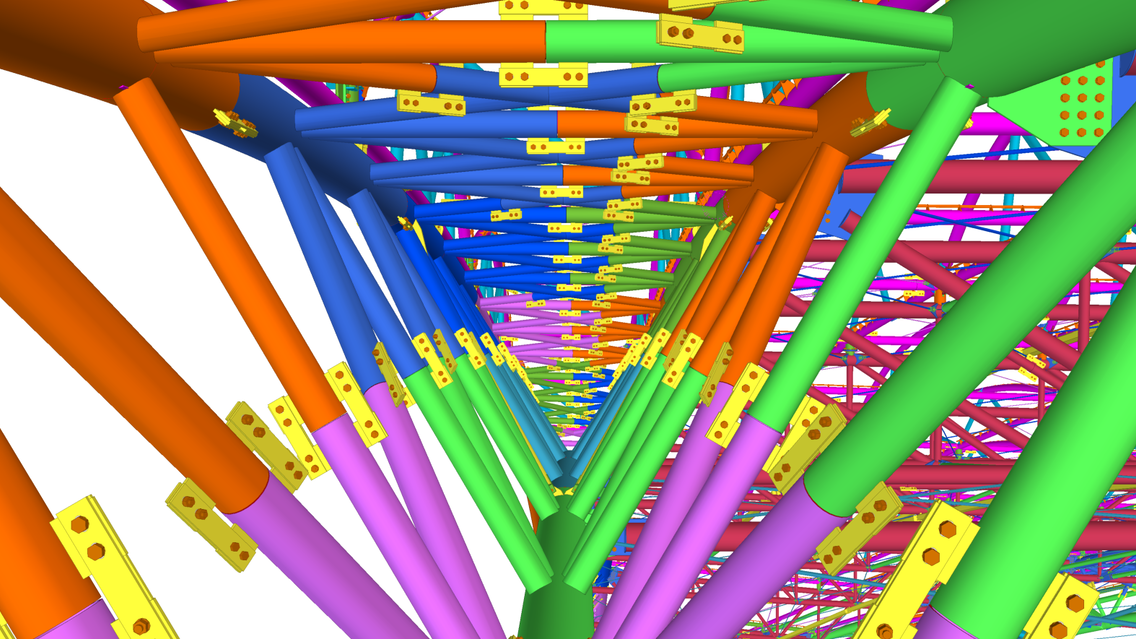

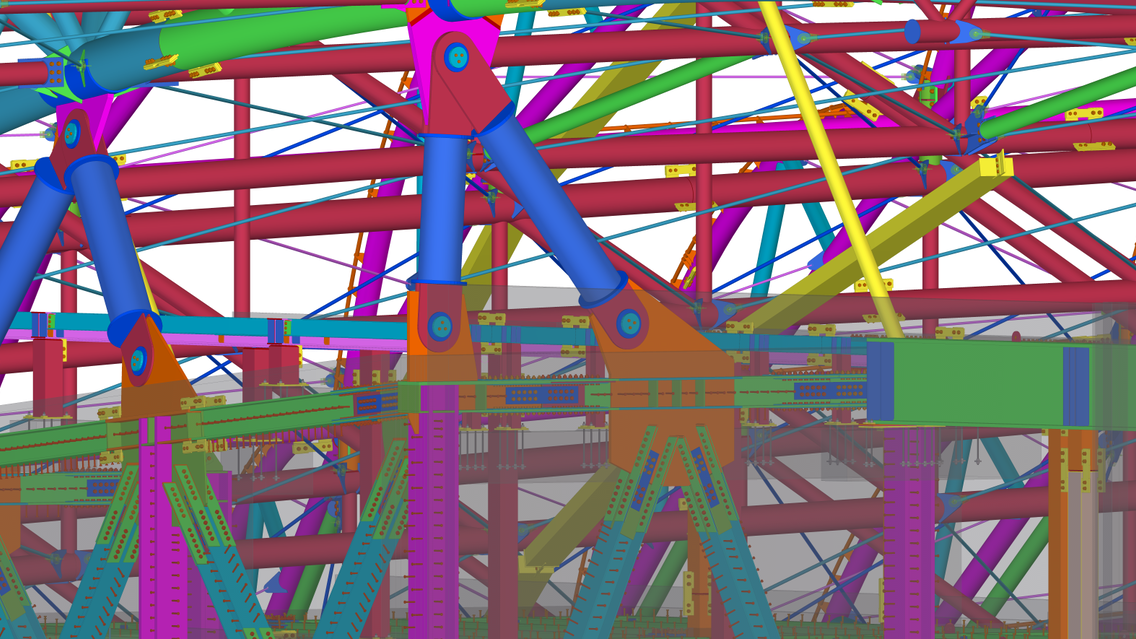

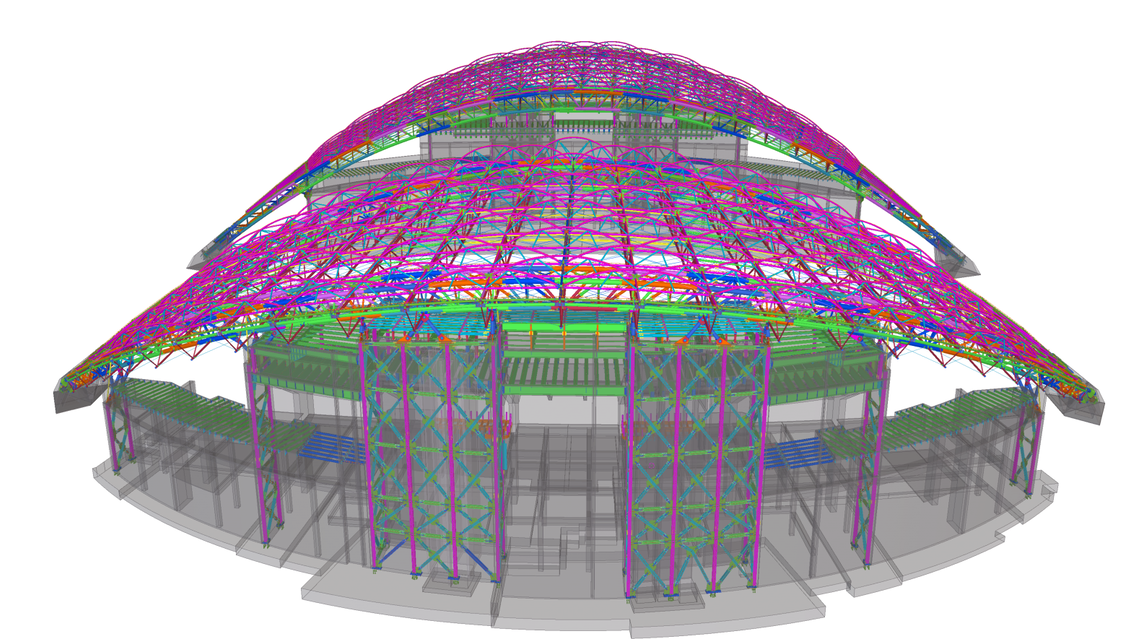

The Track & Field Stadium is having Field Area of approximately 19,150 square meters. This Track & Field Stadium consist of 2 Roofs. Each Stadium Roof consists of 2 Major Steel Arch Trusses, namely Front ArchTruss & Back Arch Truss. The Front Arch Truss is a Very Large Free Standing Steel Arch Spanning for approximately 193m Long and 43m Height. The Back Arch Truss is spanning between the intermediate Steel Mega Frames. These 2 Arch Trusses are Triangular in cross section and thus having 2 top chords and a single bottom chord made of CHS Sections. The thrust from the Front Arch Truss is resisted by an abutment consisting of a structural steel frame encased in reinforced concrete, which also supports the ends of the Back Truss.

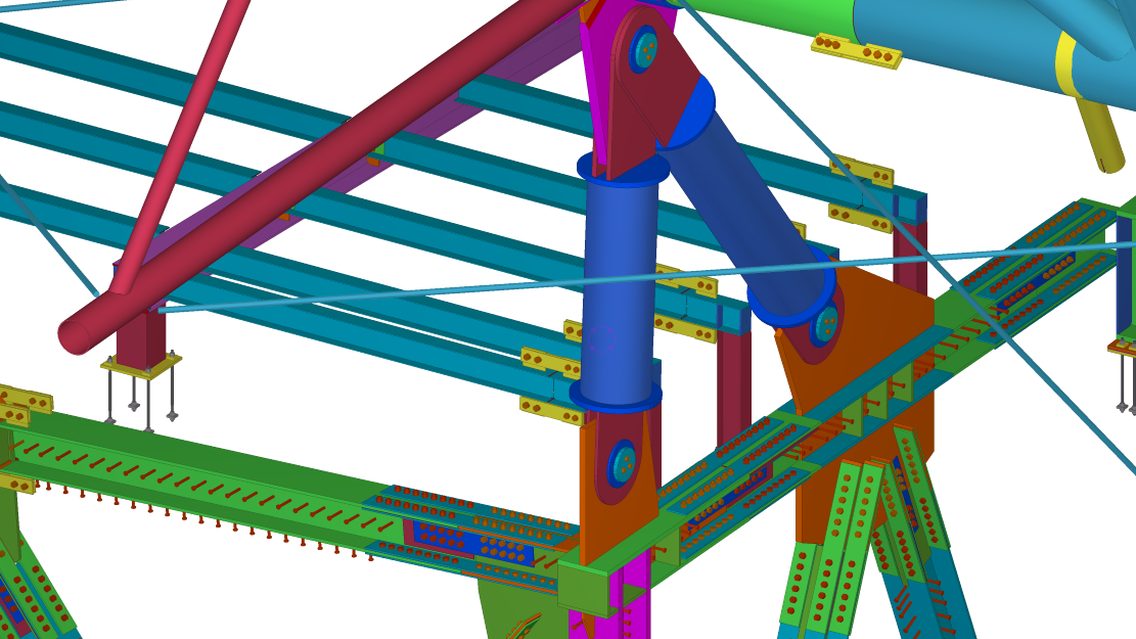

The Steel Mega Frames are Moment Resisting Braced Frames embedded in RC Columns & RC Core Walls of the Base Building. The Wind & Seismic Forces from the Stadium Roof are resisted by these Mega Frame-Core Walls and all these forces were transferred smoothly to the Base Building safely.

The Front and Back Arches are tied together by using Planar Transverse Trusses made of CHS members, Spanning 65m Maximum Length. Further, Cross-bracings were provided between the Transverse Trusses at the top and bottom chord levels in order to provide diaphragm action. CHS Bracings & Tension Rods form part of these Cross Bracings in the Stadium Roof. The top roof enclosure consists of Tensile Fabric whose are supported by Bow Trusses and their respective bracing system. This Secondary Steelwork was also done by Eversendai.

Apart from the above, the Stadium is also having the Steelwork Viewing Galleries consist of VIP Concourse Area, VIP Press Area, VIP Roof Area & Pent House Roof Area with Composite Floor Decking Slabs and these steelwork is also part of Eversendai Scope of Works.

Considering the complex interface requirements with Concrete Contractor & Tensile Fabric Contractor, the BIM Implementation and coordination played a vital role in successful completion of this project. Tekla BIMSight was used extensively to identify the clashes with other trades such as Concrete Contractor & Tensile Fabric Contractor. All the clashes were identified prior to start editing the fabrication drawings and successfully resolved with all trades, thus avoiding lot of rework in fabrication and erection. In this aspect, Tekla Software with its user-friendly platform played major role in the successful completion of this project on time.

The complex structural connection design requirements and the precise BIM coordination requirements make this project as one of the most challenging projects for Eversendai. As always with Eversendai, this project was also successfully modeled and coordinated with all other trades and fabrication drawings were released in line with the project schedule successfully.