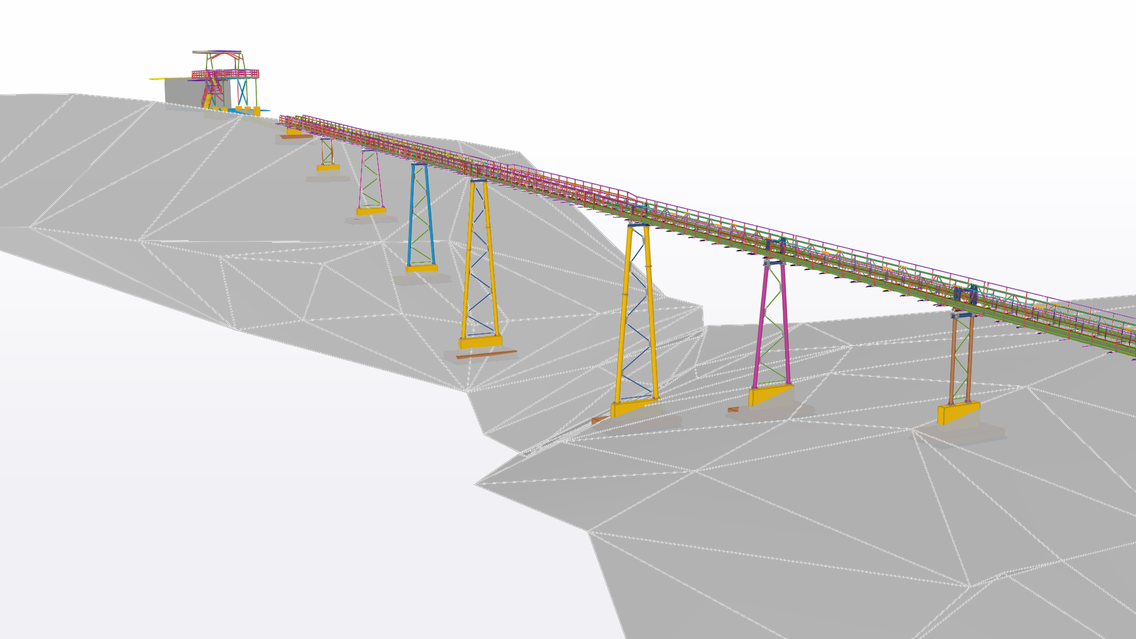

Belt conveyor located in rural Marocco

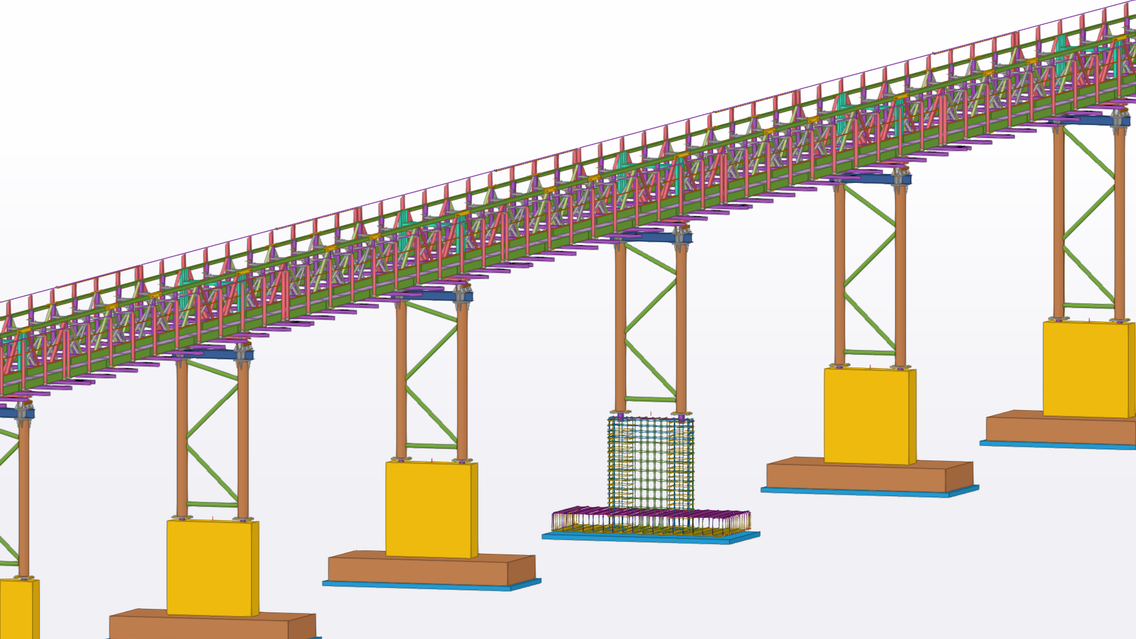

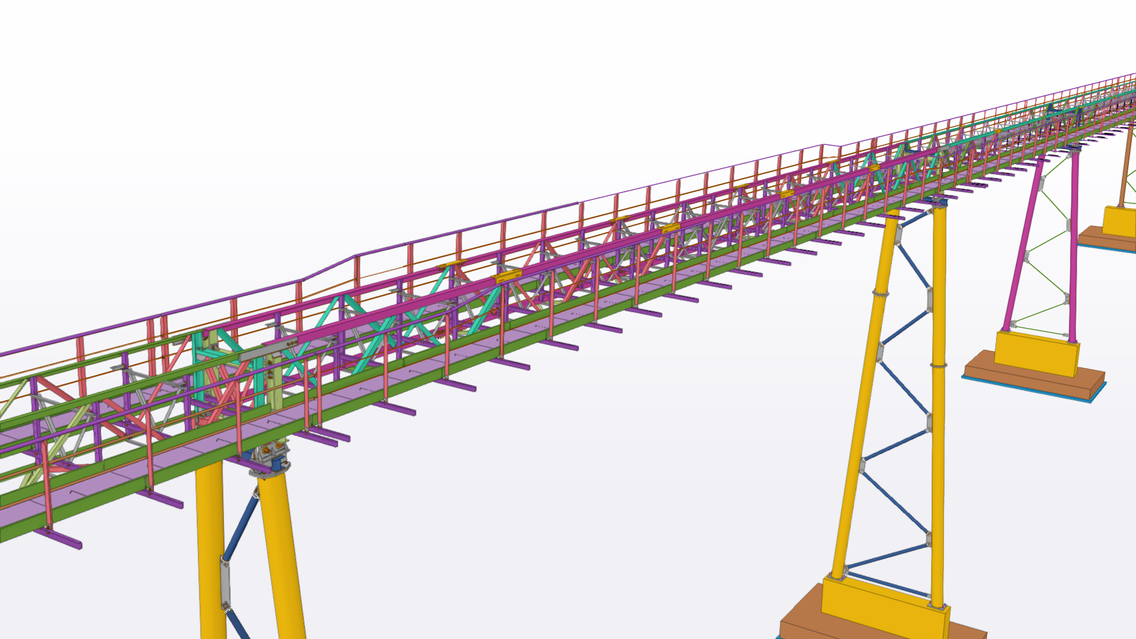

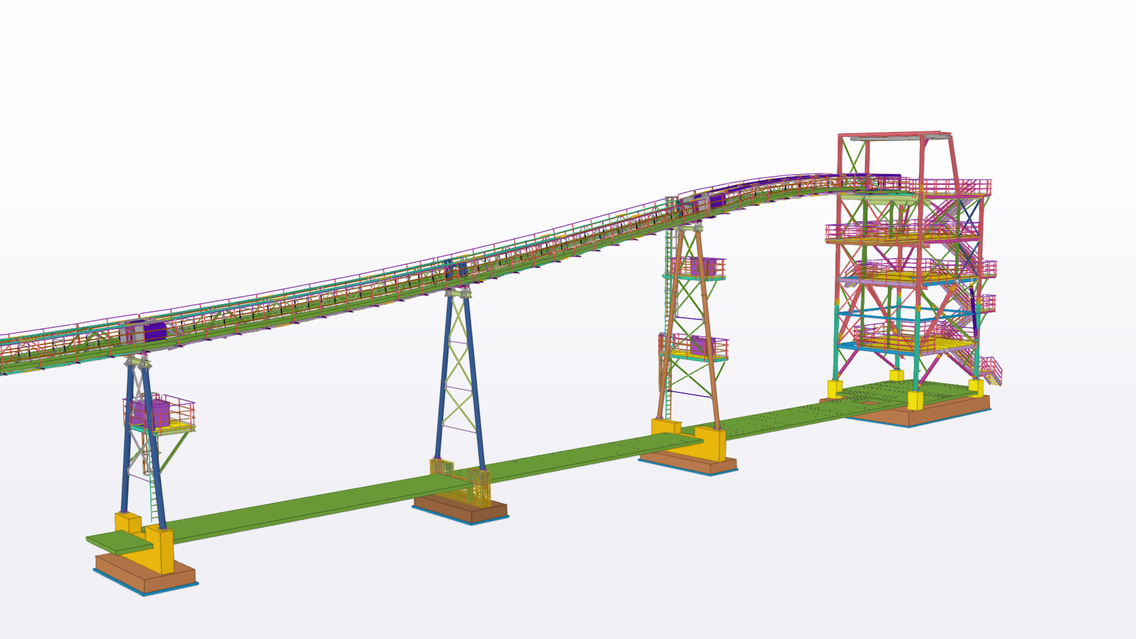

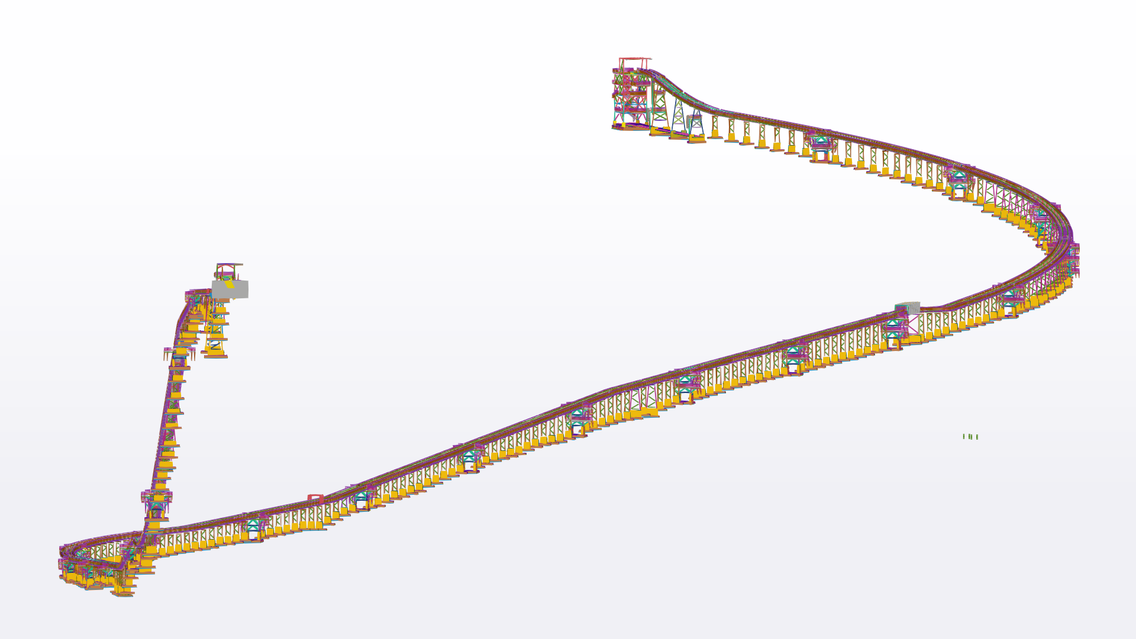

The project is a 4300-meter-long belt conveyor with a capacity of 1500 located in rural Marocco. The conveyor transports limestone from the quarry to the newly-built cement plant.

The whole project had to be completed within 20 months. Bedeschi started out by creating a topographic net, carrying out geotechnical investigations. The basic design was completed and updated as further information became available. Every part which could be called defined was sent into detailed design, ongoing when civil works started. The first steel parts could only be handled with appropriate tools.

Challenges & success factors

The most unique challenge was the time schedule. It was very tight, with only 20 months to complete the project from ’green field’ to handover. Only 3 months in the schedule allowed for engineering. Activities were shared between four parties:

- Bedeschi – basic layout and mechanical detail design

- Scola Ingegneria Srl – topographic survey, civil work, design and modelling

- BITRAVI engineering – steel structural design

- Studio d'Ingegneria Impicciatore – steel structure modelling

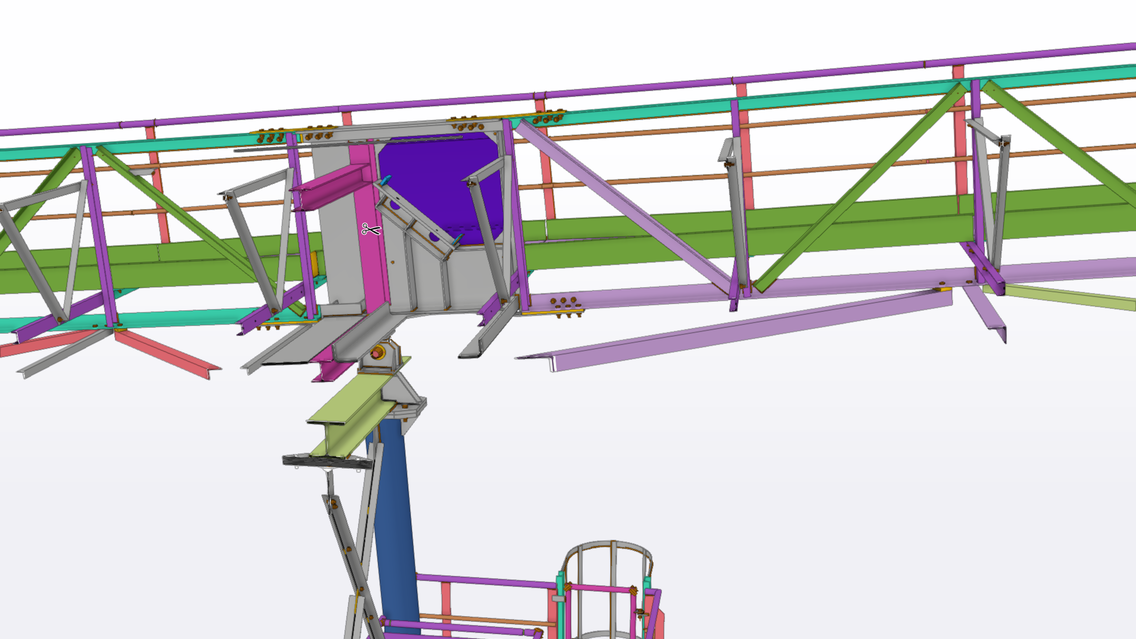

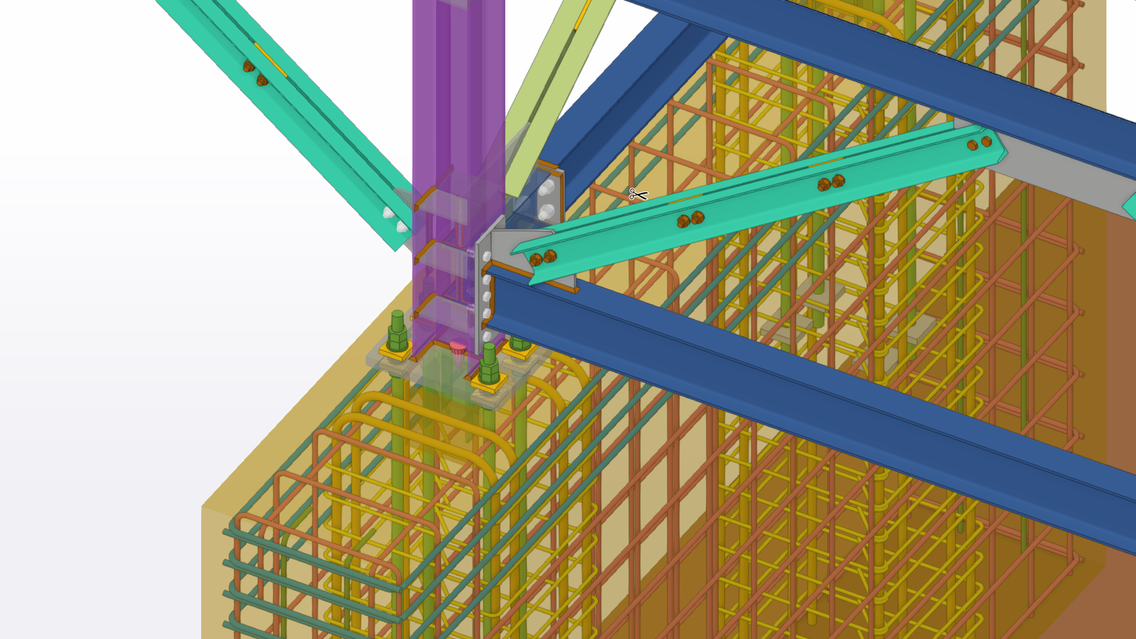

Without Trimble Connect, it would have been impossible to keep everyone up to date and make interface checks. Known errors so far are 2 holes missed in the model and 16 holes for mechanical components not in the right location. Nothing for a 4.3 km long structure.

Due to design uncertainties, constant changes were made to the model. During civil works, execution of the whole structure had to be rotated as the starting point shifted 1.4 meters. Having included the topographic information in TEKLA modeling, new coordinates could be extracted in less than 6 hours and civil works continued without interruption.

As a team we are all very proud to have been able to overcome all challenges and deliver on time. This project strengthened our belief that BIM and Tekla are paramount in the bulk handling business.

Project in numbers

- Conveyor belt: Capacity 1500t/h, length 4300m

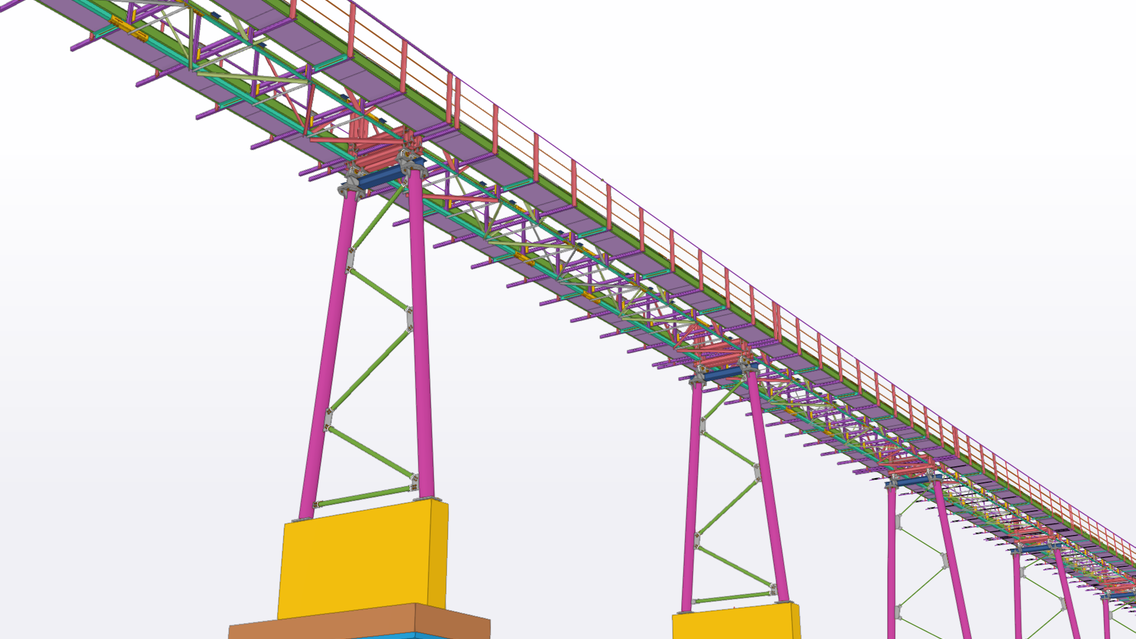

- Steel works: 2 towers (loading and transfer), 259 girders, 243 trestles and 21 fixed point towers.

- Total quantity of 1354 tons of steel, 107 tons of grating, and 25 tons of bolts.

- Civil works: Total number of foundations 265 for a total of 2478cm of concrete and 151 tons of rebar steel, formwork surface 5521 square meters.

- Due to usage of Tekla, the engineering phase was reduced by 1.5 months.

- Standardization (Custom components) of steel elements saved about 2 months in fabrication and around 6 months during erection.