The London City Island project is a residential development which will ultimately comprise the construction of 10 residential buildings containing over 1700 apartments and up to 27 storeys in height.

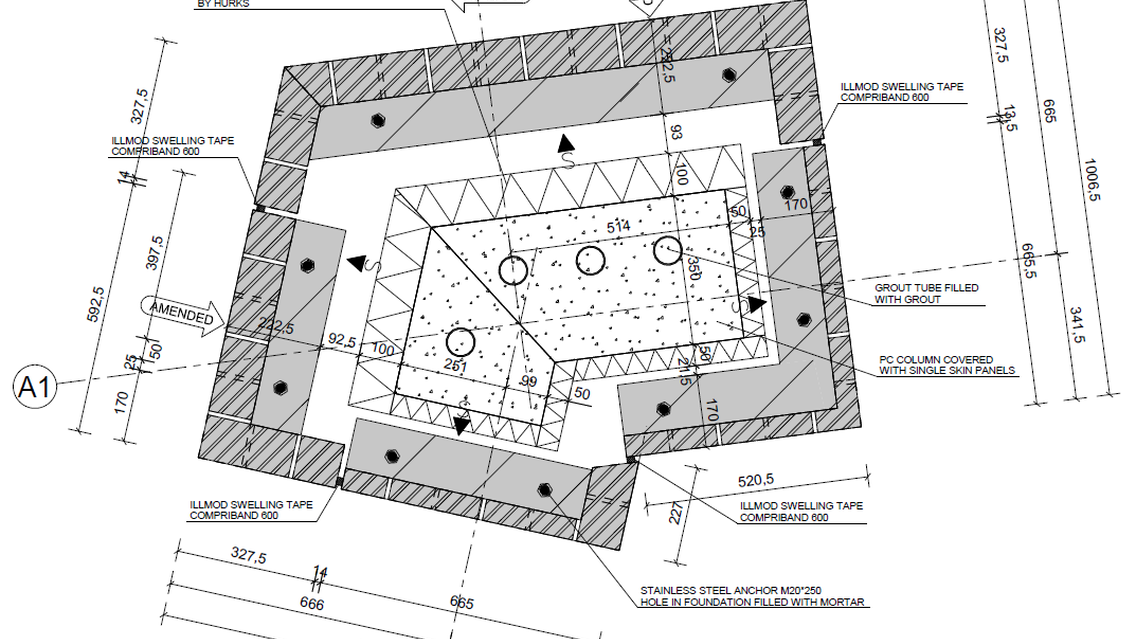

The superstructure of each of these buildings consists of an in-situ transfer slab on which the rest of the structure is formed with an entirely pre-cast concrete frame including (loadbearing) precast sandwich façade elements.

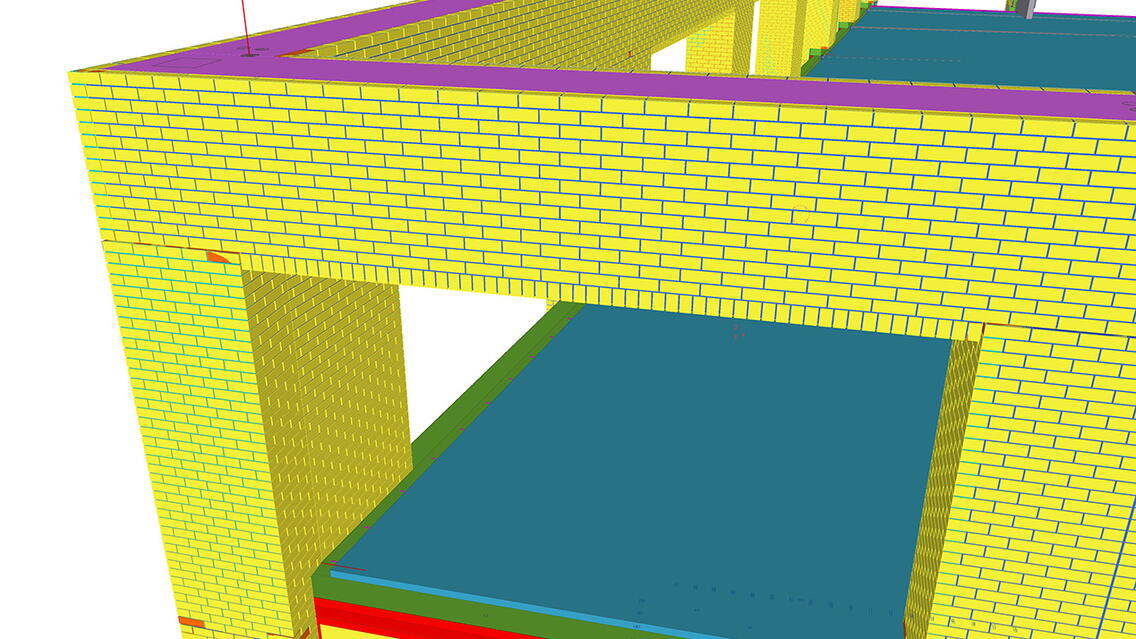

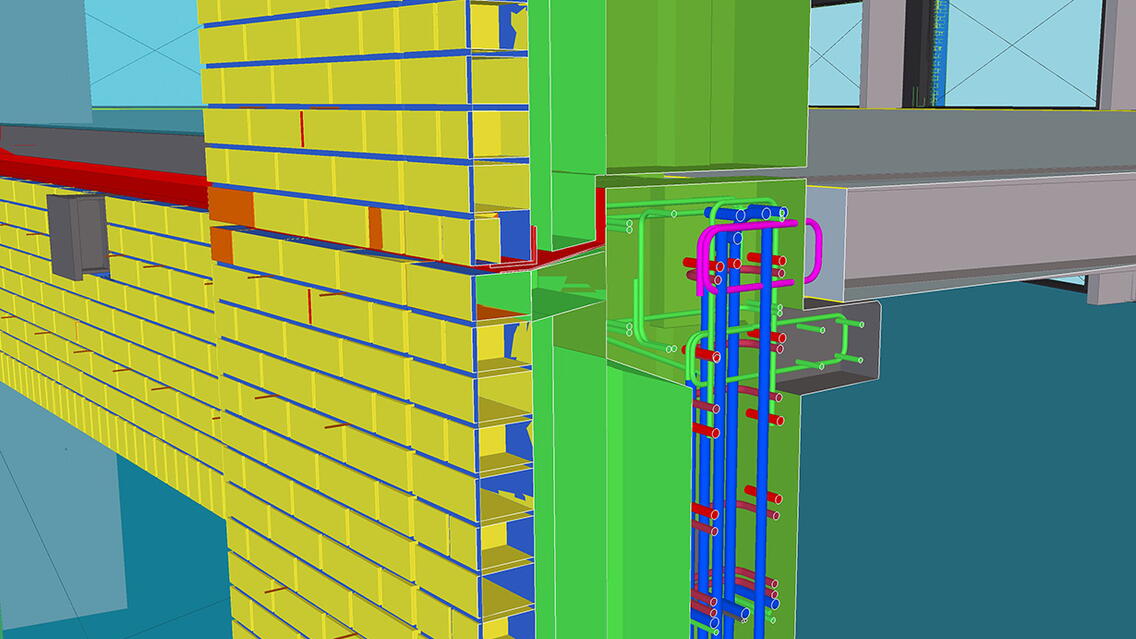

The façade element comprises an internal element of 220mm thick grey loadbearing concrete with insulation and a full width cavity, finished externally with 100mm wide brickwork (produced with a full brick). The windows & glazing are installed in the façade elements at the factory yard in Veldhoven, The Netherlands. Once completed, the panels are transported to London by truck and ferry.

The cavity varies in width from 25mm to 300mm in order to accommodate the deep reveals required around the external windows and balcony doors. Another challenging factor is that all buildings have different corners, not being 90 degrees. Therefore, the elements have very complex detailing and a lot of embeds. Every component of the precast elements has been modelled in Tekla, including brickwork, reinforcement, masonry supports, balcony brackets, ventilation and wall ties. The brickwork has been modelled in separate models to ensure an acceptable modelling pace. The main model and brickwork model are combined using IFC to check for correctness.