Renowned for both its distinctive architectural design and its exceptional dedication to supporting individuals with cancer, the newest Maggie’s cancer support centre is situated in the grounds of the Royal Free hospital in London.

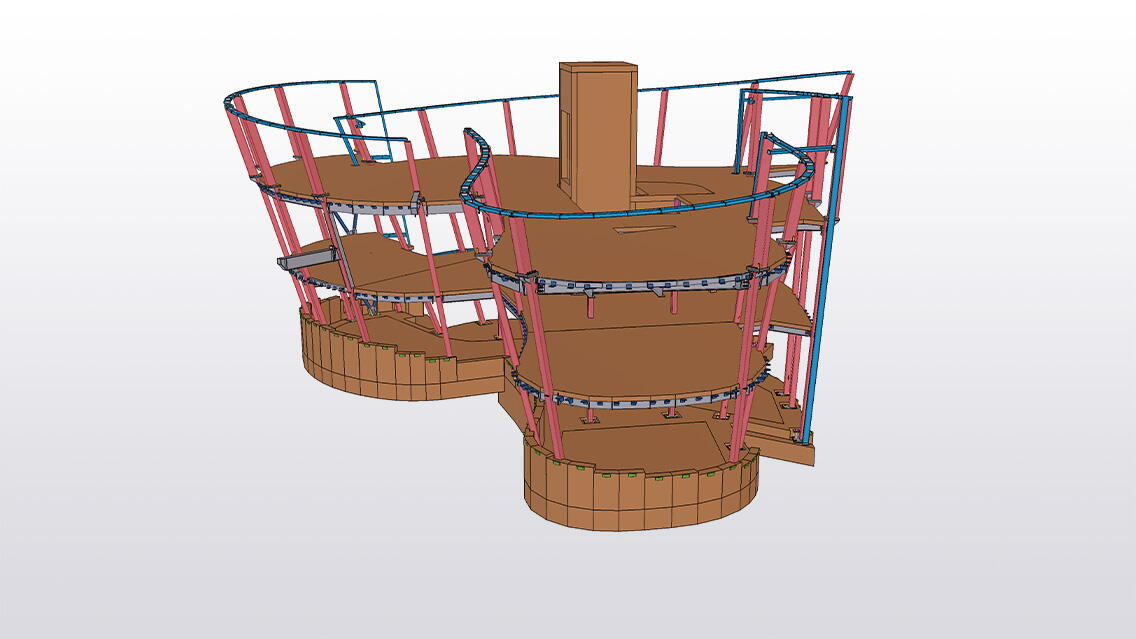

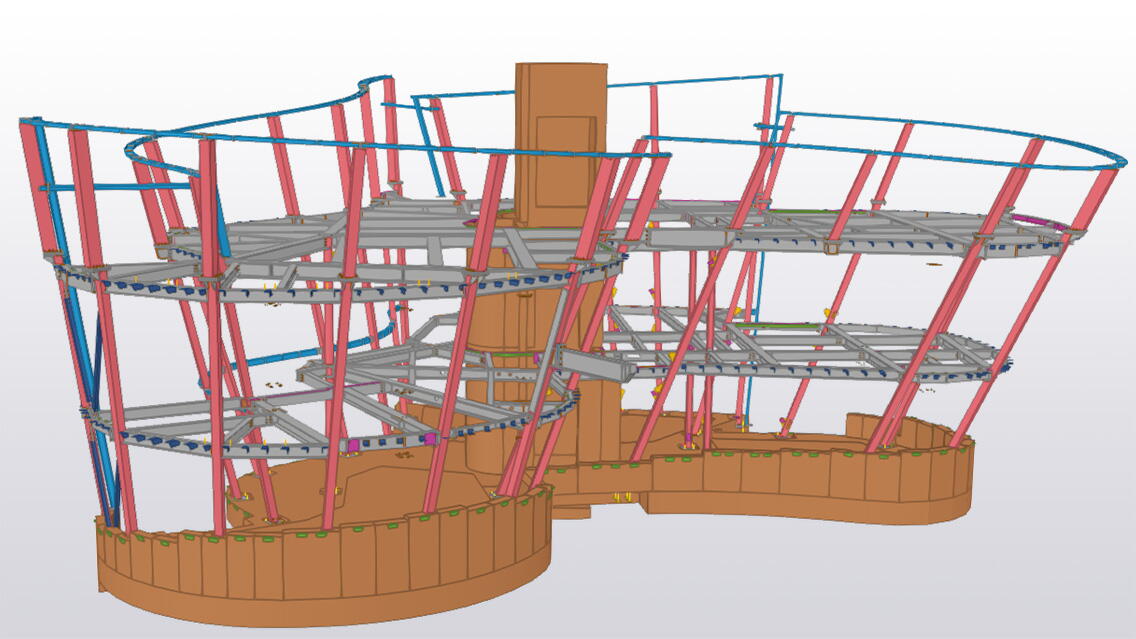

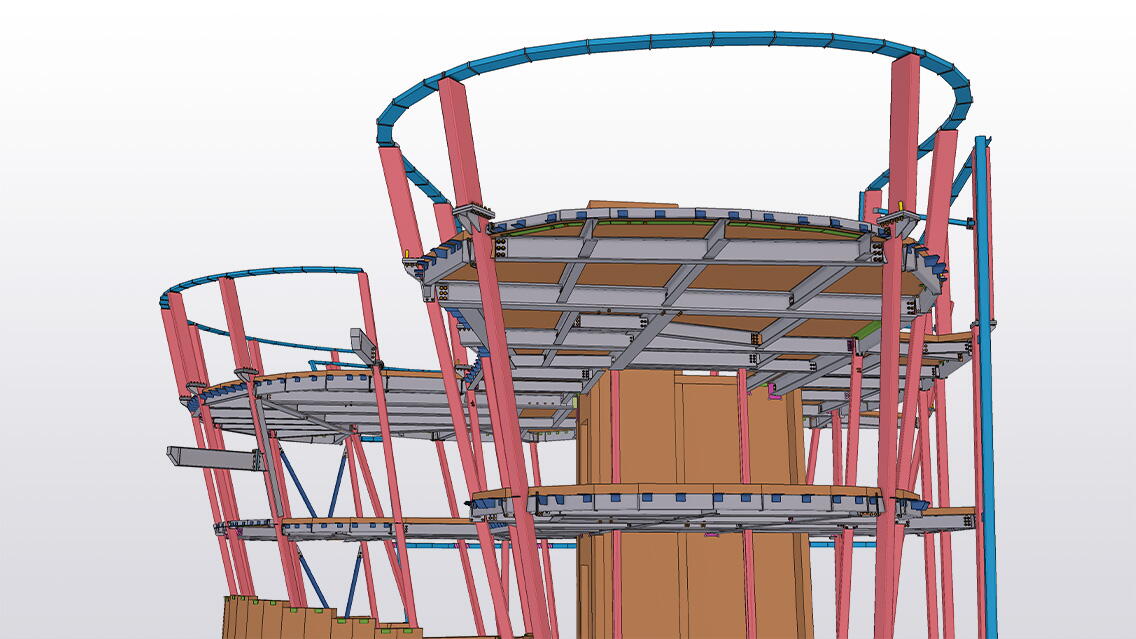

The building showcases a custom raking curved facade, distinctive external fins, and a secluded rooftop garden and pavilion. With its curved external form, inclined walls and rooftop garden, this diminutive yet architecturally bold structure set the engineers and client team a big challenge.

The Maggie’s cancer support centre project was a special one for William Hare as it was charitable in nature; having the opportunity to contribute so strongly to the support of anyone with cancer or their families has been described as ‘an invaluable opportunity’ for the team involved.

Challenges and achievements

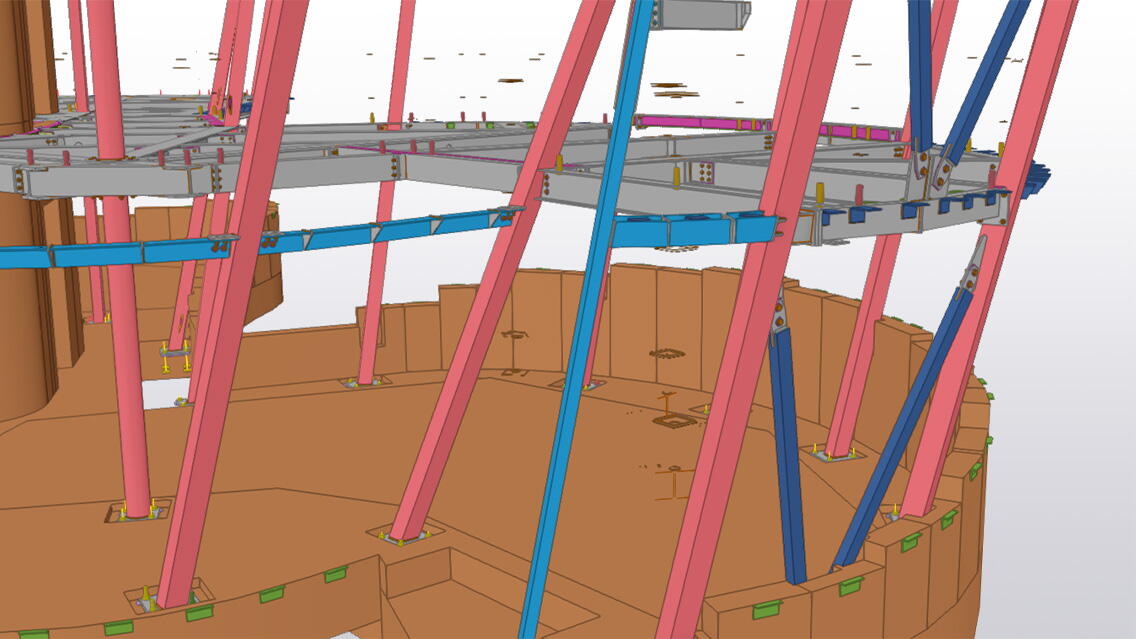

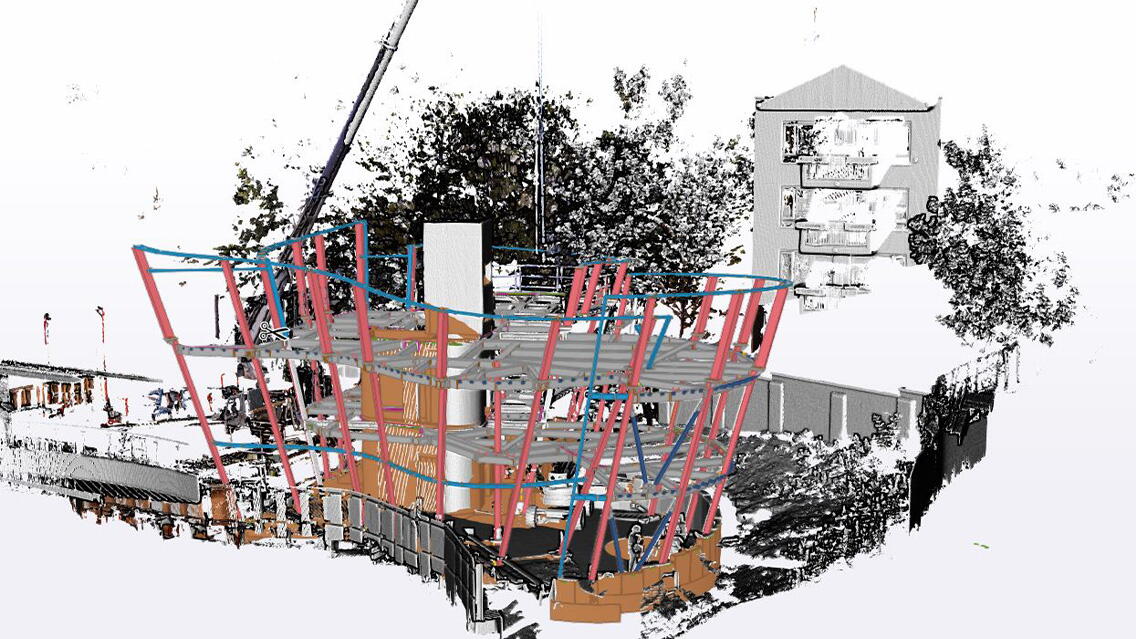

The Maggie’s cancer support centre project had a very challenging geometry, with every edge column of the curved facade raking in two directions. Due to the complexity of the geometry, this project demanded a more integrated approach than usual, including an enhanced use of 3D resources available within Tekla software. This allowed William Hare to effectively communicate design information between all stakeholders, including the client and their consultants.

Using Tekla software

- Almost all of William Hare’s production plant relies on model data (primarily NC data) for cutting and drilling of both profiles and plates. Robotic fabrication undertakes automated assembly and welding that uses XML files extracted from the 3D model.

- A very prescriptive build sequence was developed by construction and temporary work design teams and communicated to permanent design and detailing teams via Trimble Connect, using premium features (bespoke property sets to enable easy selection for view creation and, ultimately, an animation portraying the build sequence).

- Communication with other stakeholders in this project was primarily in 3D, with the preferred file format being IFC. However, NWD, Revit and 3D DWG files were also shared.

- Several custom components historically developed by William Hare are used on the majority of projects undertaken, and the Maggie’s cancer centre project was no exception. The application of Cellshield, a temporary edge protection system, makes use of this feature.

- UDAs used by the William Hare team enabled data to be passed between different model files, and for holding data of apps created both in-house and by a third party. This data can then be called up on drawings as required, and also be made available in Trimble Connect through IFC export or mapping for .tekla exports.

What does William Hare Limited say about the project?

“The total cost of the Maggie’s cancer support centre was approximately £8 million, however it included some incredible charitable donations of time and materials from all parties involved in the project. BIM was instrumental for the delivery of this project due to the complex geometry; as such, the majority of design information was exchanged between parties in 3D formats.”

- Sian Gilbertson, Bid Manager at William Hare Limited