Development

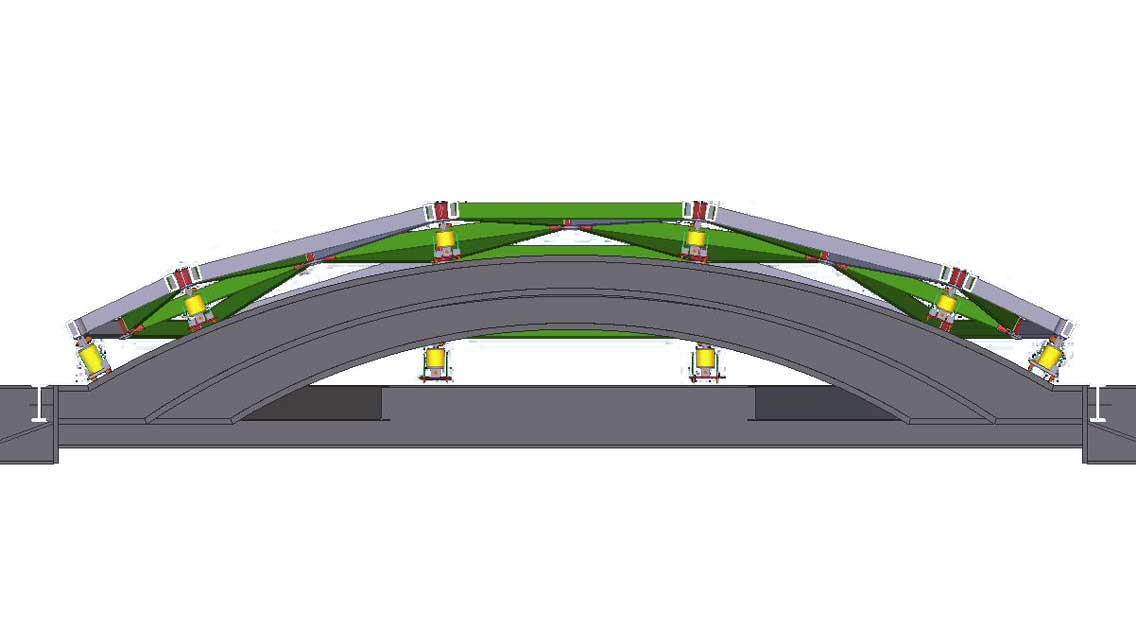

The largest shopping center in the Netherlands, the Mall of the Netherlands, was built in Leidschendam. One of the eye-catching features of the shopping center is the central hall. Over the central hall, an oval-shaped glass canopy has been placed, called the Dome. Vic Obdam Staal was commissioned by Ballast Nedam to fully design and assemble the Dome. The Dome is unique because it is placed on hinged pendants. Each part is turned at an angle to the adjoining parts.

Challenges

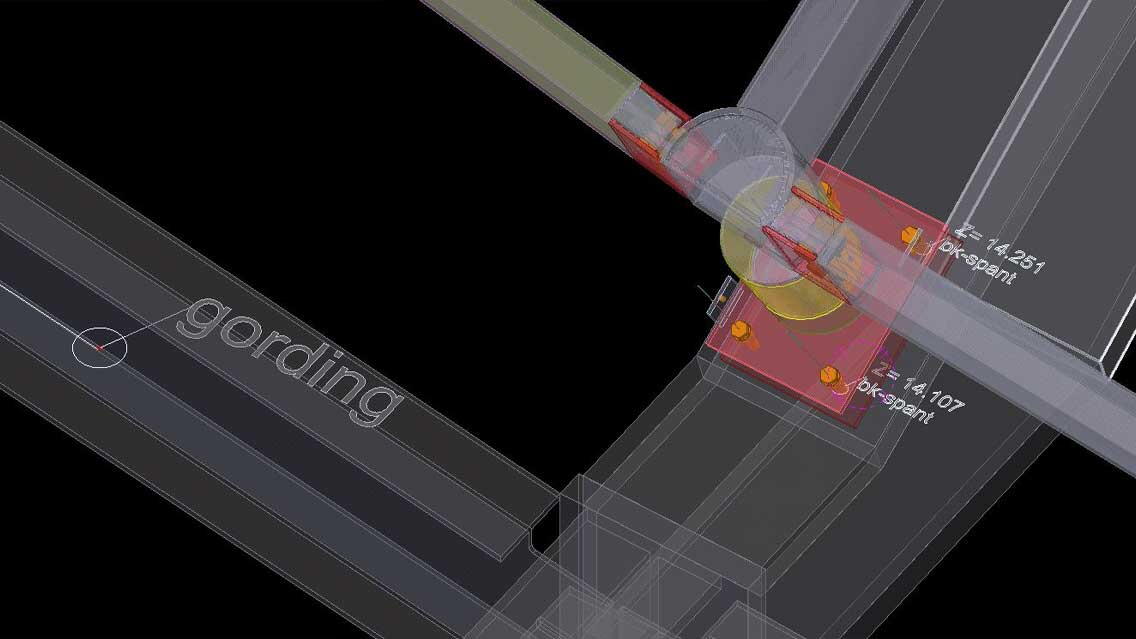

At first glance, the construction seems fairly simplistic. But if you zoom in on the nodes, you see that every beam is slightly twisted in relation to the junction.

Due to the oval shape, limited glass tolerances, and the aesthetic requirements, each node is unique with its own freedom of movement. The challenge lay in the angular rotation of each beam, which led to only identical parts, all of which had to be modulated and assembled separately. In the production, this was overcome by scribing all the connections to the tubular profiles of the pendulums.

From an aesthetic point of view, the requirement was that all the tubes should come together by means of ‘blind’ connections. The decision not to weld on the work resulted in a design in which a unique fitting piece was made for each joint. Because of the fitting pieces, all connections are executed as bolted connections without being visible.

BIM

The entire pendulum construction was calculated on the basis of 3D calculations so that the movement of the construction could be taken into account. The Dome construction has been placed on top of an already placed steel construction that has moved unpredictably due to its weight. By means of a total station 3D measurement, the existing steel arcs were mapped, and the pendulum lengths were adjusted accordingly. In the same way, all the anchor points of the shuttles were plotted.

As Vic Obdam built on a 3D subsurface provided by an external party, the Dome construction also serves as a subsurface for the glass plates. The glass plates and the steel construction were matched within the glass tolerances in 3D engineering sessions.

Project parties

Goudsticker – de Vries; Structural Design

By means of: BIM: 3D models matched

IV-consult: Joint design

Pendulum joints calculated

Braat glass constructions: Supplier of the glass roof

By means of BIM: 3D models tuned

Ballast Nedam: Client

By means of: BIM: Checking dimensions of the model

Measuring and plotting the anchor points on the arches using 3D measuring points.