Building

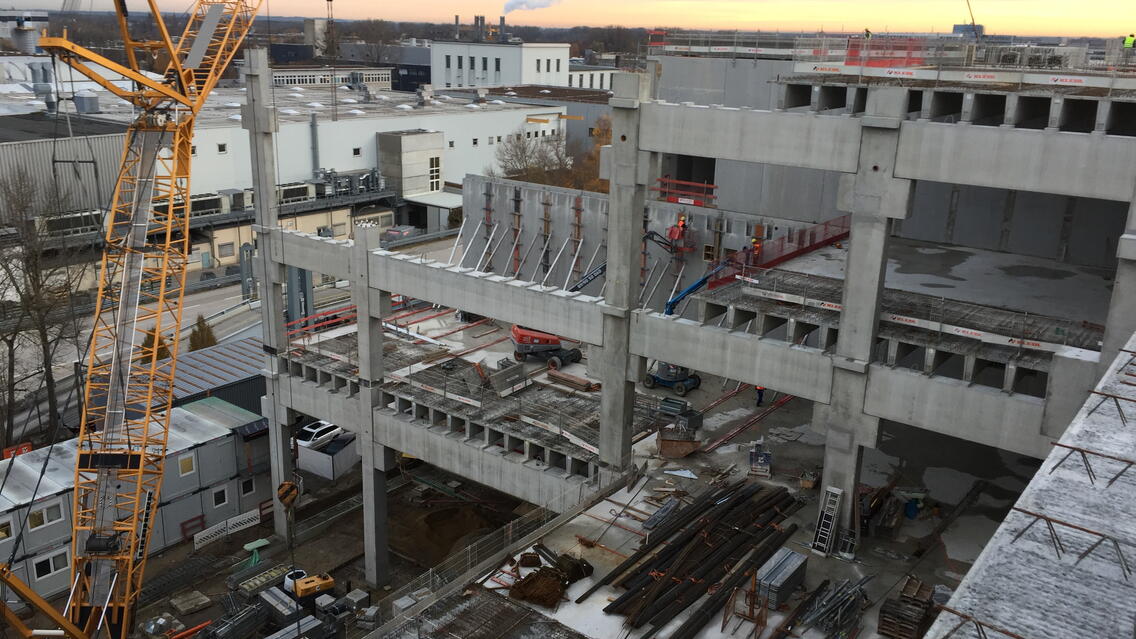

A new research and development center for the vehicle prototypes of the future is currently being built on the grounds of MAN Truck & Bus AG in Munich. The center provides space for 450 employees and will contain office space, workshop areas, measuring stands and laboratory areas for research and development departments as well as a separate warehouse with a fully automated high-bay warehouse. Bau-Consult Hermsdorf (BCH) took over the complete precast concrete planning, including investigation of the construction conditions and the preparation of an assembly concept.

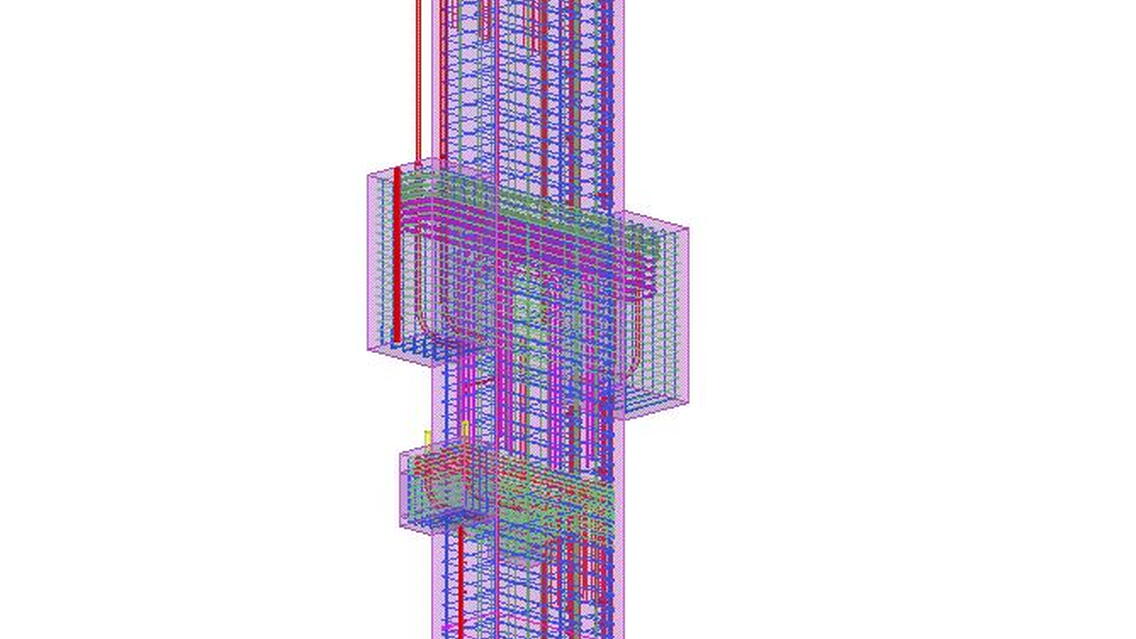

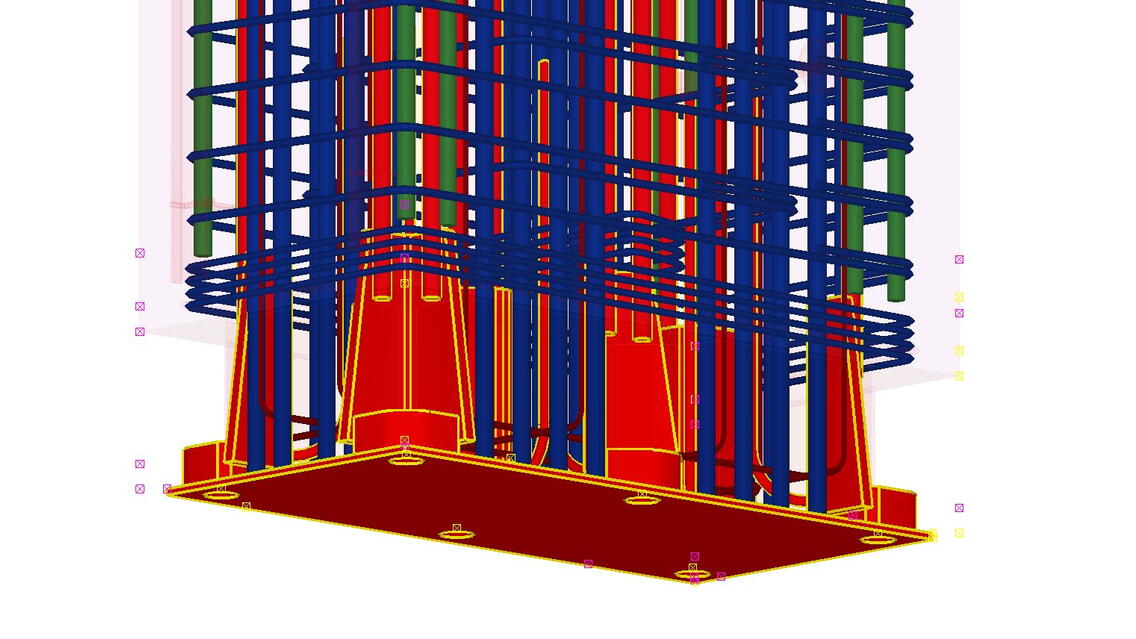

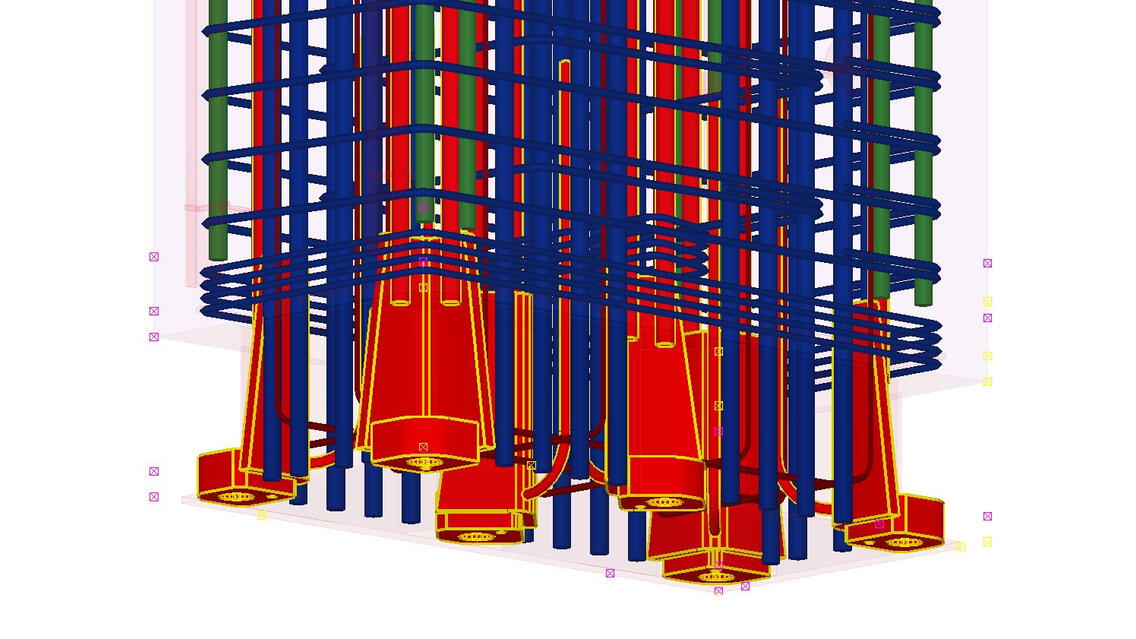

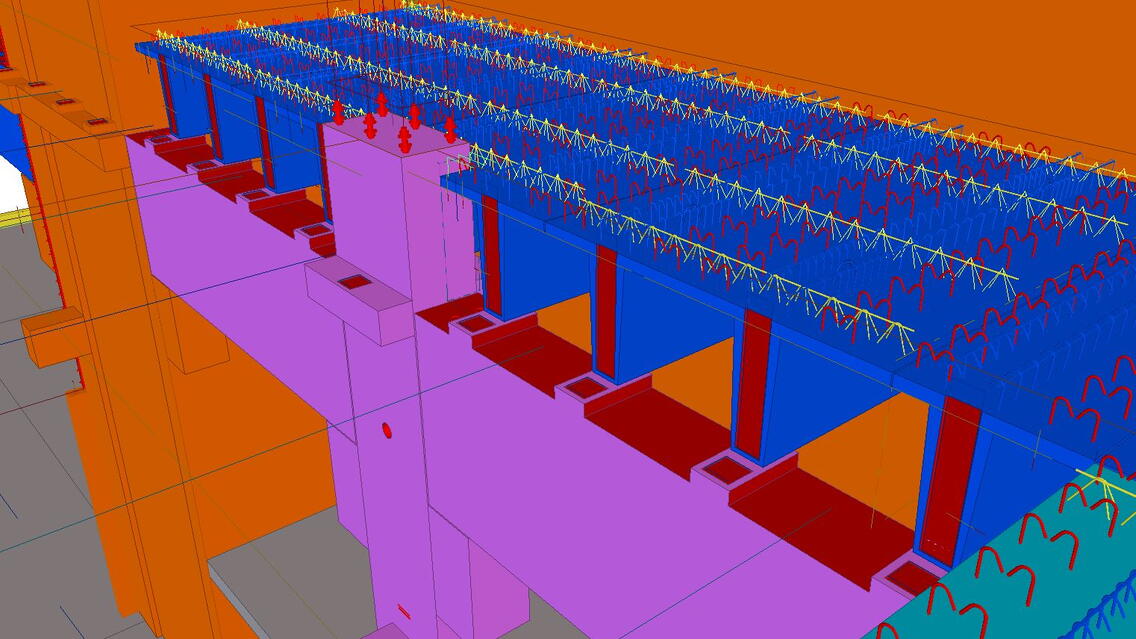

The flexibility of usage had a very high priority in the realization of the construction project. Therefore, ceilings with large spans (approx. 16.5 m) were planned. Particularly noteworthy as well are the dimensions of the beams and columns, which were challenging due to the high ceiling loads in the detailing of the reinforcement and the nodes.

Construction

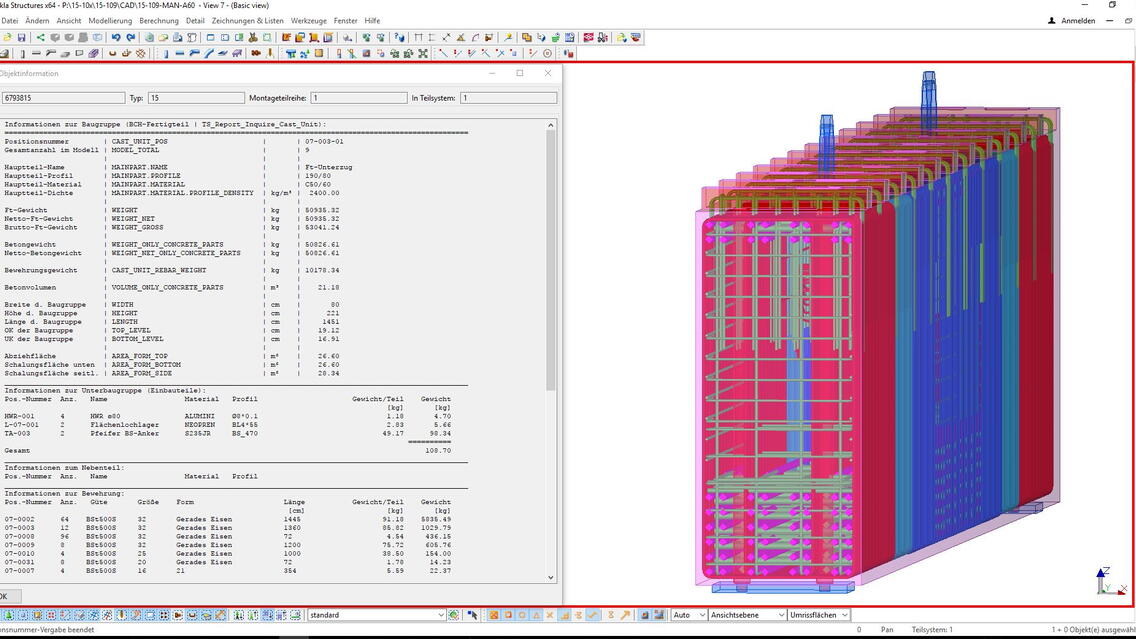

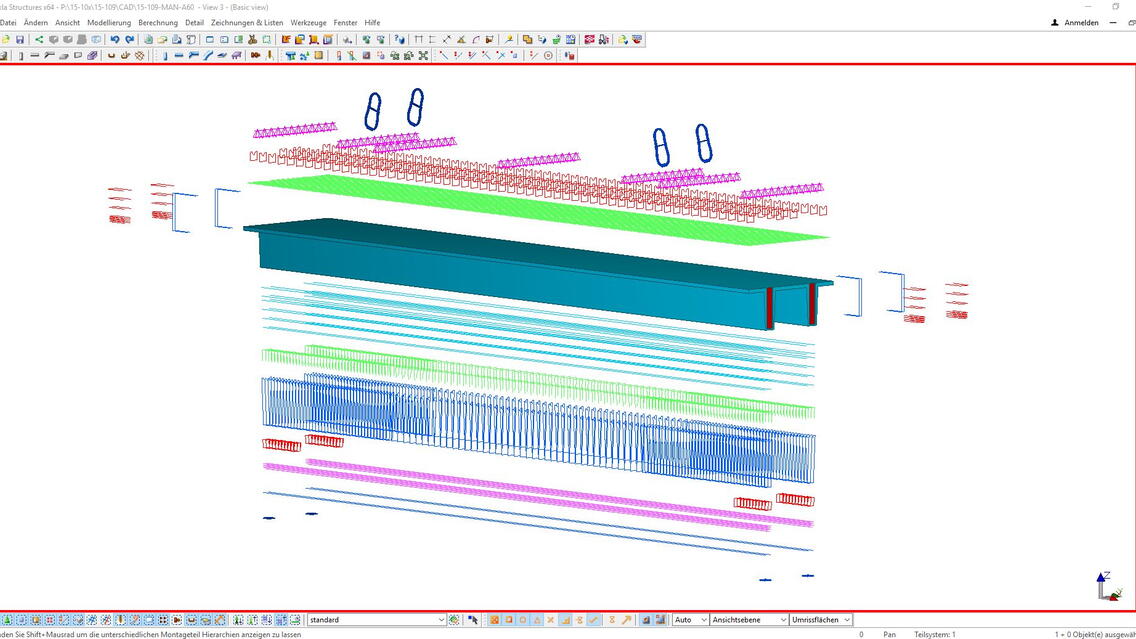

Tekla Structures’ ability to manage large numbers of elements and data volumes was fully exploited in this project. All precast concrete elements were reinforced in the model and fitted with mounting and assembly parts. This reduced the modeling effort considerably.

In addition to the purely geometric information, the components (CAST_UNIT) carry further data, e.g. status information. The data was exchanged via IFC, BVBS and Unitechnik interfaces, as well as 2D drawings and lists for the parts order. For example, approx. 800 Peikko connections were installed. A constructible model served well for this type of prefabricated joints with very high accuracy of fit required.

All cast-in-place concrete components, such as staircase cores and foundation bodies, were modeled as well. This led to error-free realization, despite a large number of interfaces with the precast elements.

Good possibilities for project data exchange helped the planning team in many ways. The facade substructure and the planning of the precast elements could be realized in close cooperation with the steel construction planner on basis of the IFC data.

The detailed visualization significantly supported communication with the construction site. Difficult junctions could be discussed in a simple and time-saving way. This enabled solutions to be found together and construction processes to be discussed.

Benefits of Tekla Structures and BIM

- Tekla Structures’ capabilities for managing large element counts and datasets

- In-house parts catalogs bring enormous time savings in projects

- The detailed visualization considerably supports communication with the construction site

- Good possibilities for data exchange