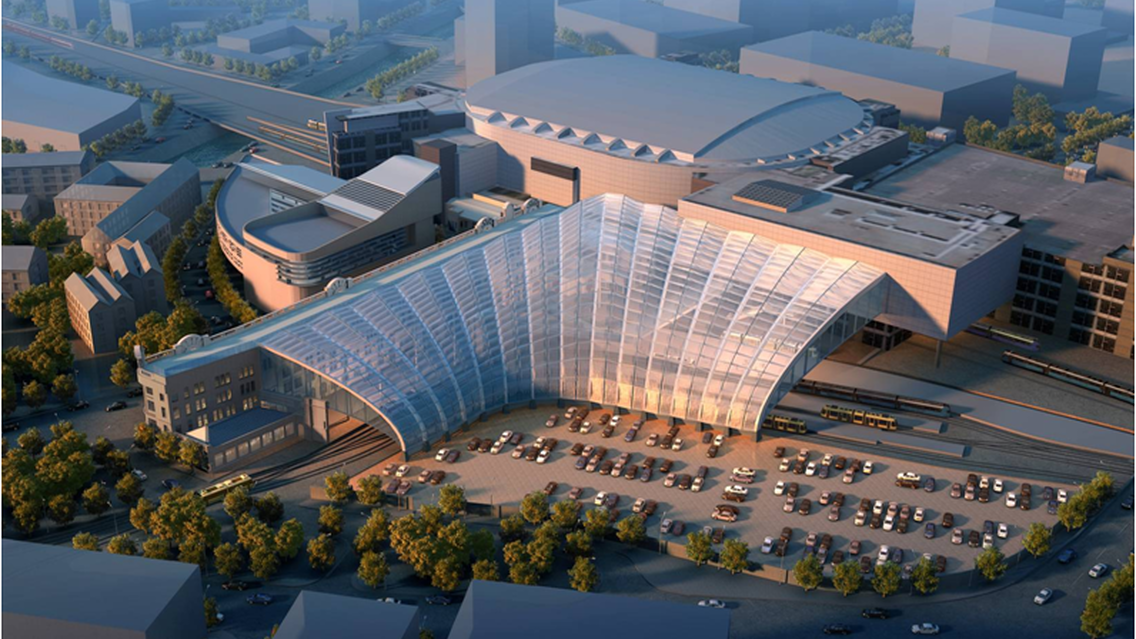

The intention was to dramatically revamp Manchester Victoria and provide its train passengers with a stunning facility and a much brighter future overall.

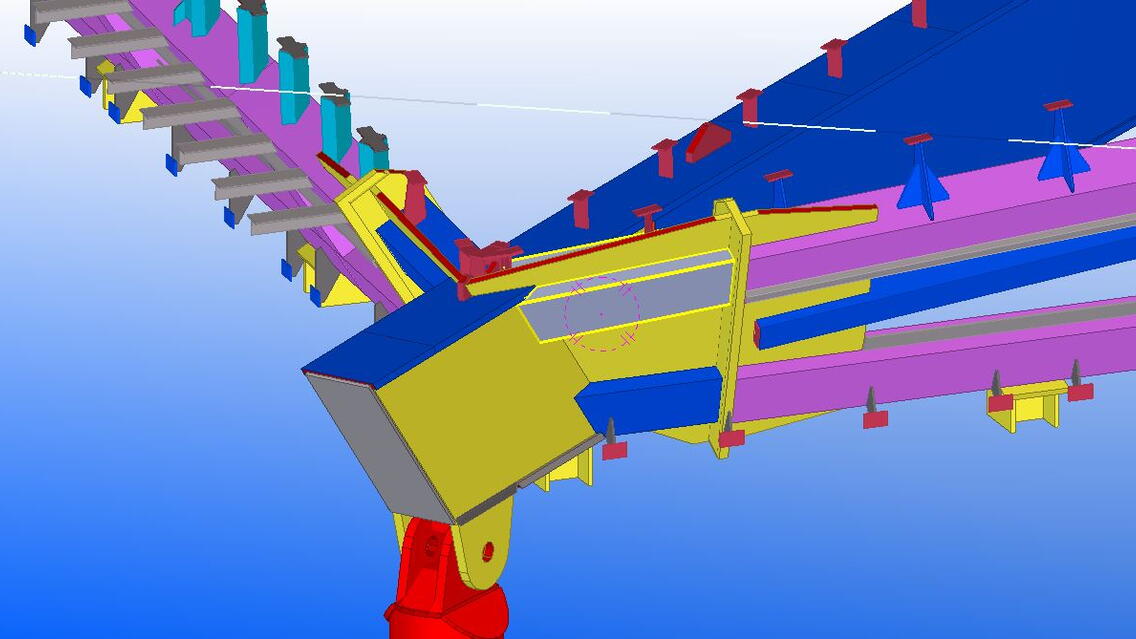

Severfield and Lostock started modelling with a revit export .ifc model from Hyder. However, it was then imported into Tekla – Severfield's chosen software for BIM and Structural Steel fabrication management.

At a very early stage in the project the company realised that the feature 'ribs' had to have a pre-set within them. The eibs were detailed and fabricated to a preset geometry. This ensured that the roof would take up its theoretical geometry as closely as possible, once the ribs had deflected under the dead load of the roof.

We therefore had two different Tekla models working independently, one pre-set geometry for the 15 ribs and one non pre-set for the Purlins, Tertiary structures and the Mezzanine link to the Arena.

We also used the AutoCAD 3D DWG file from the cladding subcontractor, Vector, to enable Tee Saddle positions. These covered both the roof structure and its gable ends. Severfield overlaid this as a reference file onto both models.

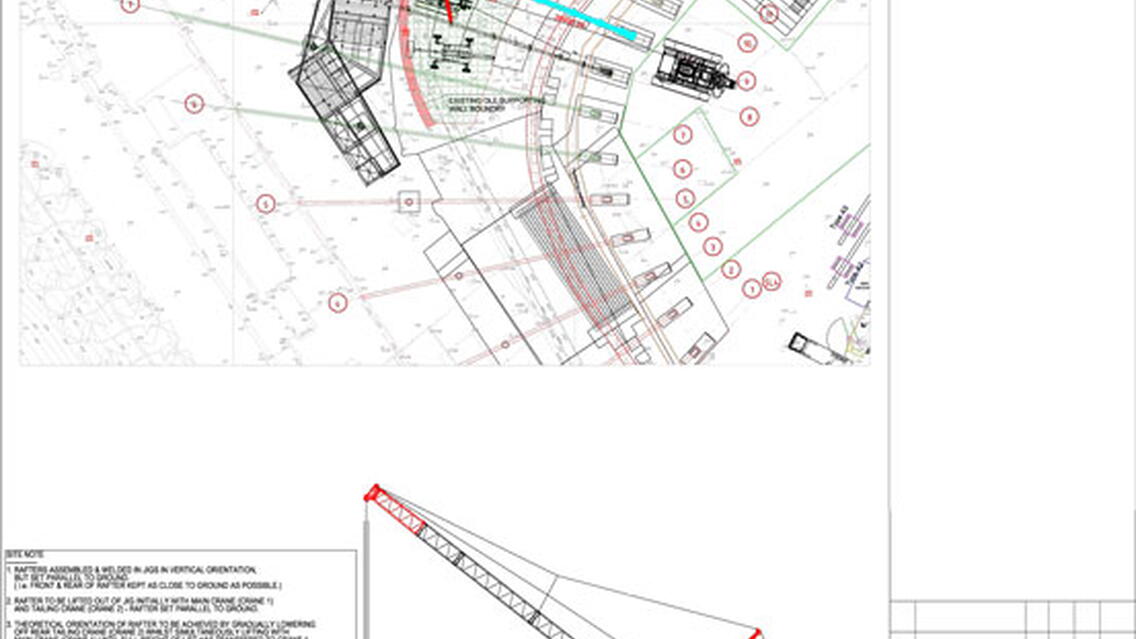

The next step was utilising the model for Construction Sequencing in Trimble SketchUp and 3D Max for rendering.

The model was also used to create a temporary works assembly jig for constructing the 15 numbered ribs on site in both plan and vertical states, which were called 'The Toast Rack'.

All surveying on site, temporary works and erection hand over was completed using the Tekla model via 3D DWG Exports.

Working closely with Morgan Sindall at weekly meetings, Severfield used site based plans on a regular basis to show areas available for other activities, including: access, crane locations and also to show how they would be able to complete its works prior to key erection periods that could only happen during possessions and importantly, the isolation of both Network Rail lines and the transport for Greater Manchester Metrolink.

Indeed, drawings created in Tekla helped to provide task briefing to site staff and clarified and explained its lifting methodology.

During a 6 month erection period, working 3.5 hour shifts between the hours of 01.30 hrs and 04.00 hrs, Severfield and Lostock, successfully installed all of the structural steelwork with help from Tekla and its BIM capabilities.