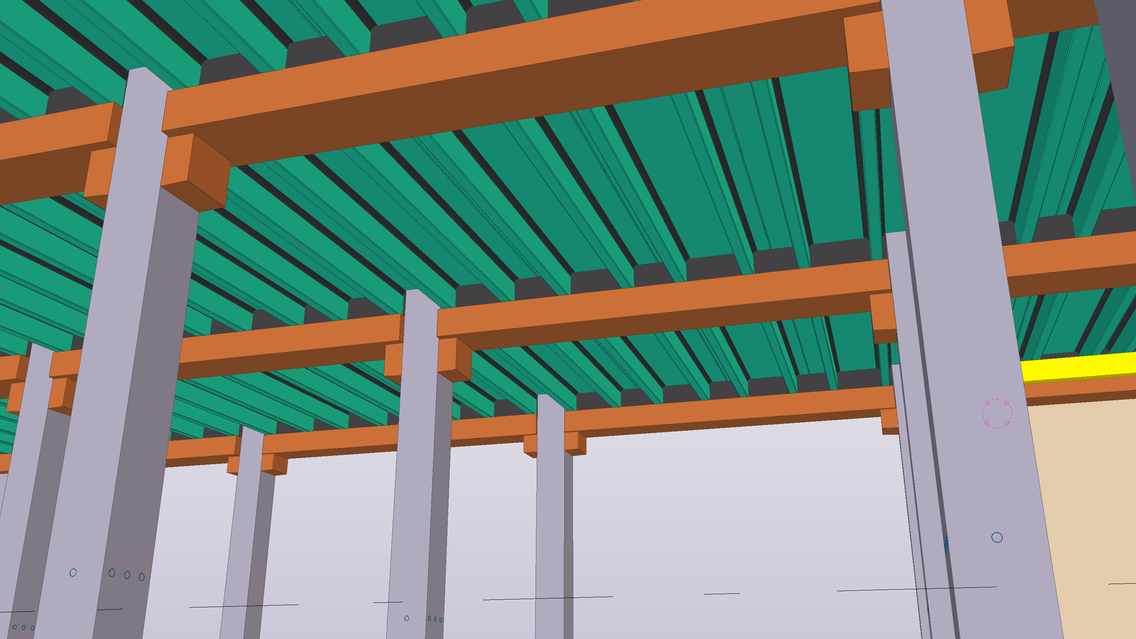

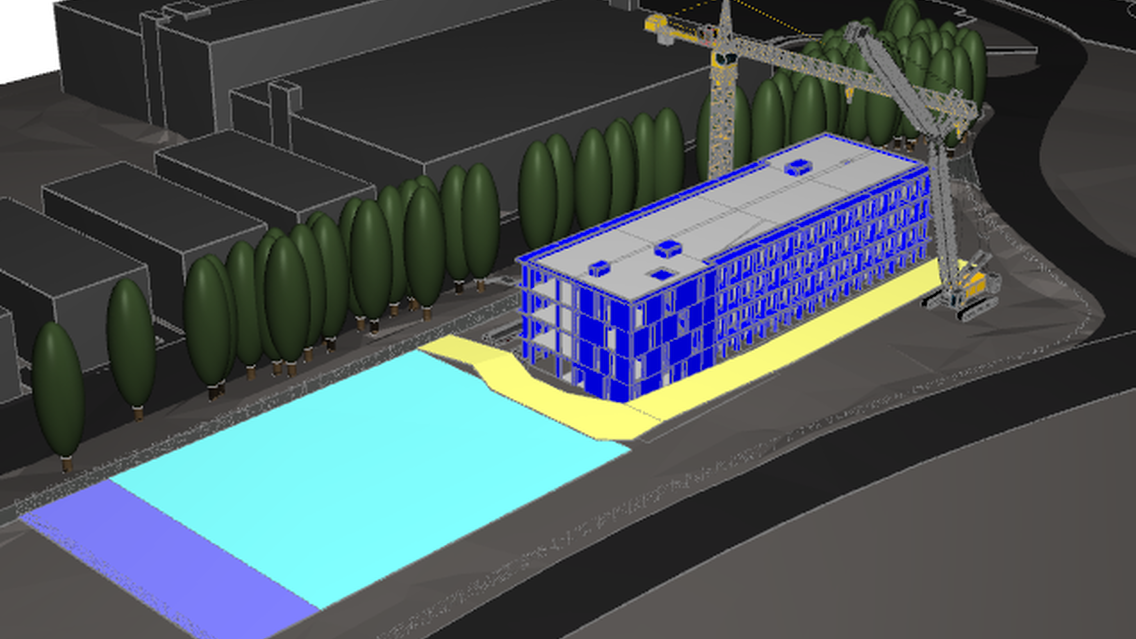

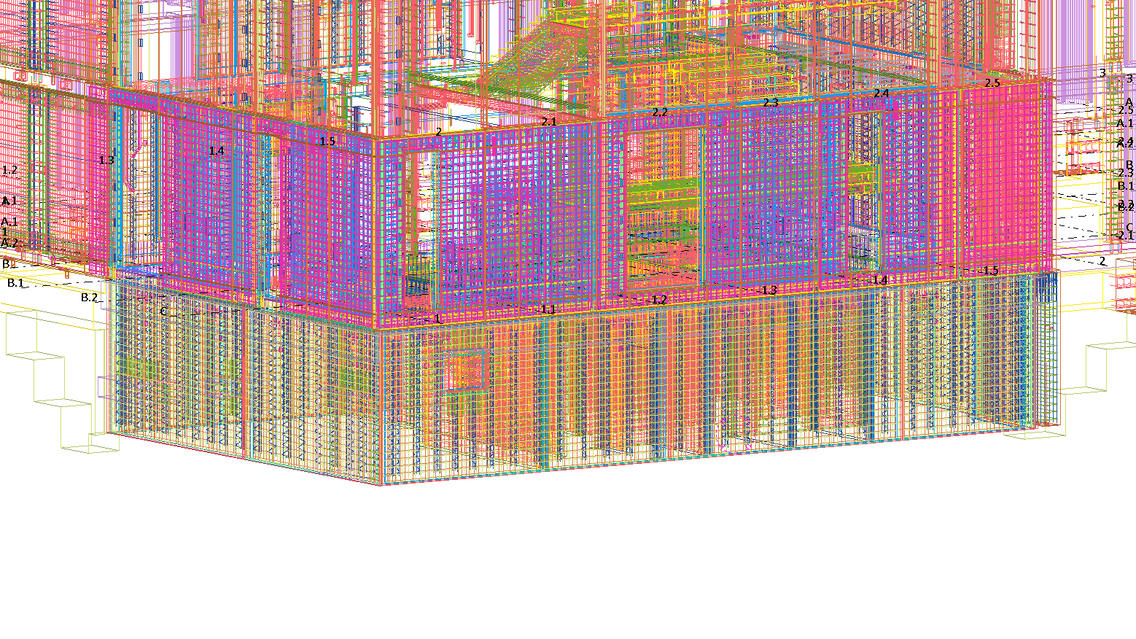

On the Max Bögl premises in Sengenthal, Germany, the first building of the new Max Bögl Campus is currently under construction as a combined precast and cast in place project. 2,850 tons of precast elements and 4,200 tons of cast in place concrete are utilized. The building has dimensions of approx. 65x20 meters and is 15m high.

Precast design and coordination is undertaken by the company's own engineering office.

Tekla and BIM

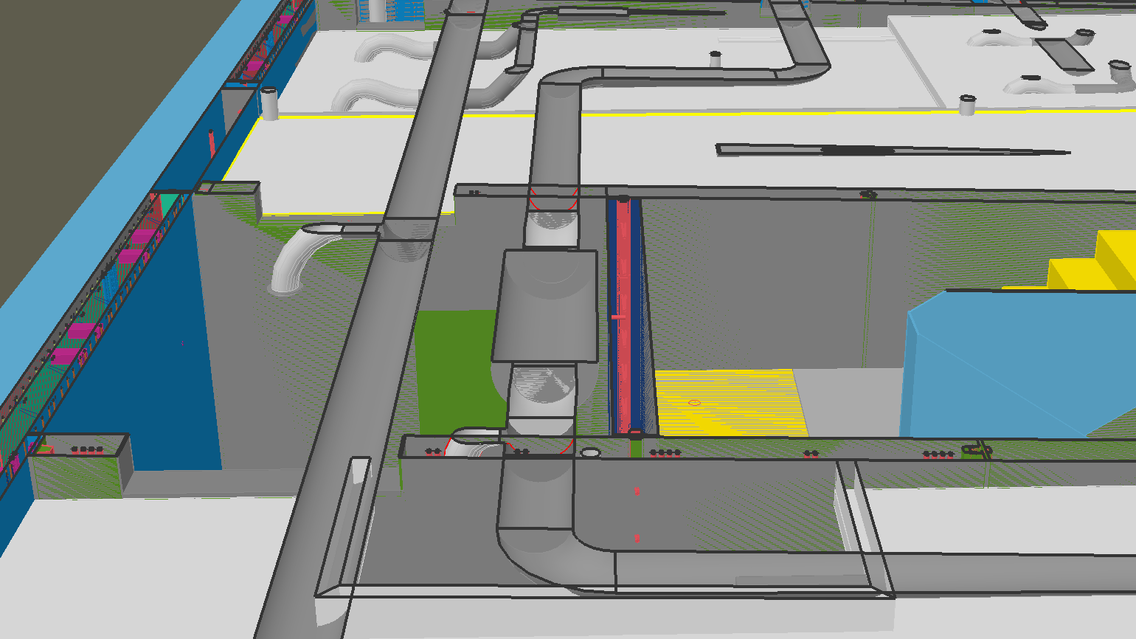

Using Tekla Structures, precast plans are produced for double walls, concrete walls and sandwich walls, stairs, columns and foundations, as well as respective general plans.

Especially for precast panels, the interfaces to fabrication are very important, for example Unitechnik data for the circulation plant and mesh welding and BVBS data for the bending machines. ln order to ensure high data quality for the circulation plant, Max Bögel has been using the company's own development "MB Fabrication Export". The application enables the team to export various fabrication data at the same time. In the background, checking mechanisms are able to sort out over 80% of incorrect data in advance.

An additional application developed by Max Bögl for Tekla Structures is the ,”MB-Planlauf-Tool". This tool enables the team to maintain drawing release (cycle) information in the model. Past use of Excel tables is not necessary anymore. lnstead, the Tekla database is used as a single source. The information in the model is exported every night with the help of the Tekla BIM Publishers via CPlxml format and published in Desite MD and its web application. The past days’ planning status is always available online.

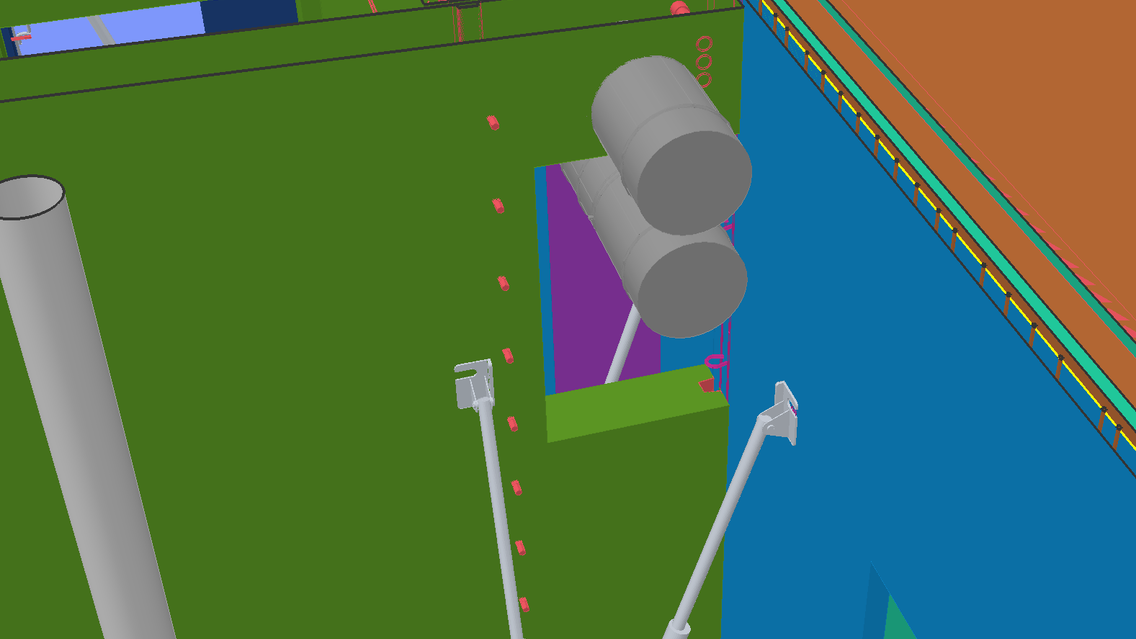

Two helpful warehouse applications utilized are the ,”Construction Sequencer" and the ,”Crane Capacity Check". The first is used to plan and visualize the erection sequencing of the precast elements. The latter checks the weight of the individual precast elements in relation to the crane and its position.

The stairways are planned with architectural concrete requirements. Therefore the position of the supports in the double walls is also very relevant. Planning of erection supports and the resulting position of screw plates are done in Trimble Sketchup.

Additional BIM applications in the project

- Use of an augmented reality app to get an early overview of the project onsite

- Quantity takeoff is done with in RIB itwo with the help of a Revit Model.

- 3D planning of construction site set-up

- Quality assurance and problem reports and checklists on tablets

- 360' photo documentation

Partners:

Architectural design: Bögl Gierer Architekten GmbH

Landscaping: Studio VuIkan Landschaftsarchitektur

Structural Engineering: GP Dr. Grossert Planungsgesellschaft mbH

HVAC/MEP: Seidl & Partner Gesamtplanung GmbH for HVAC (HLS)

Electrical: Firma Burnickl lngenieur GmbH