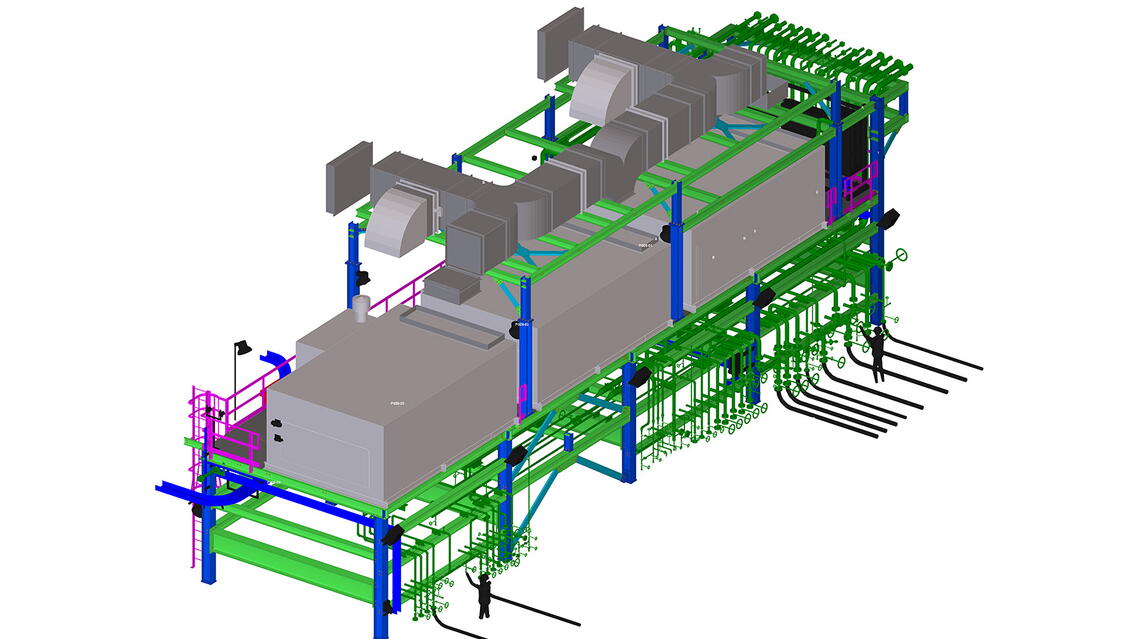

This modularized industrial project was a true showcase of integrated BIM from design through fabrication. Utilizing a reconfigured process of model exchange and approval, combined with a creative implementation of customized model transfer technology; this project was completed entirely paperless, ahead of schedule, with no RFI’s.

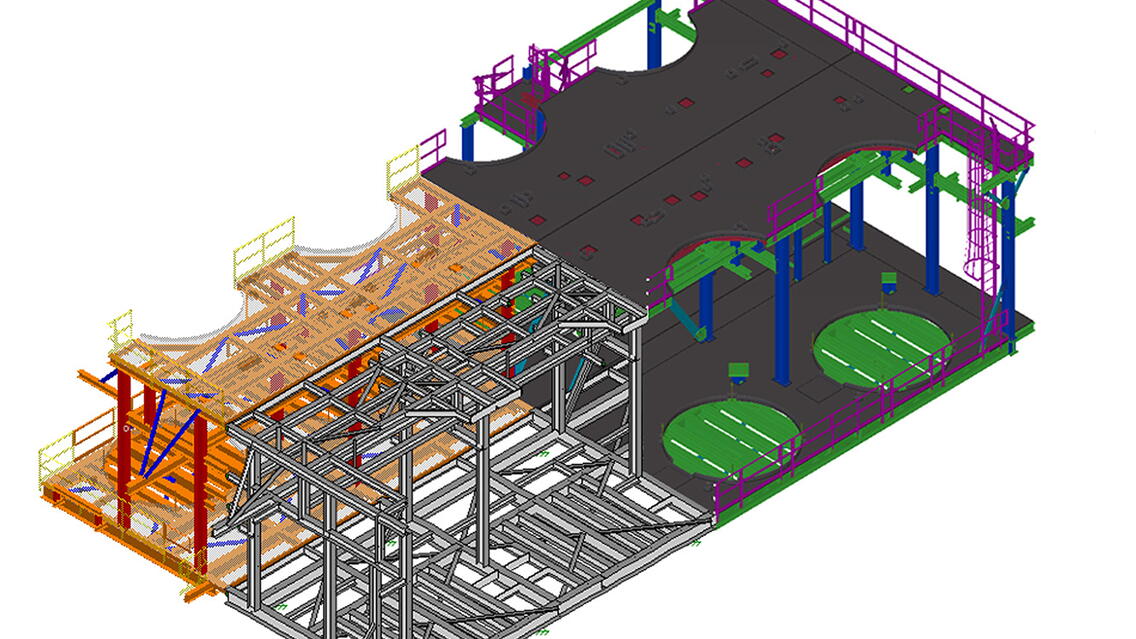

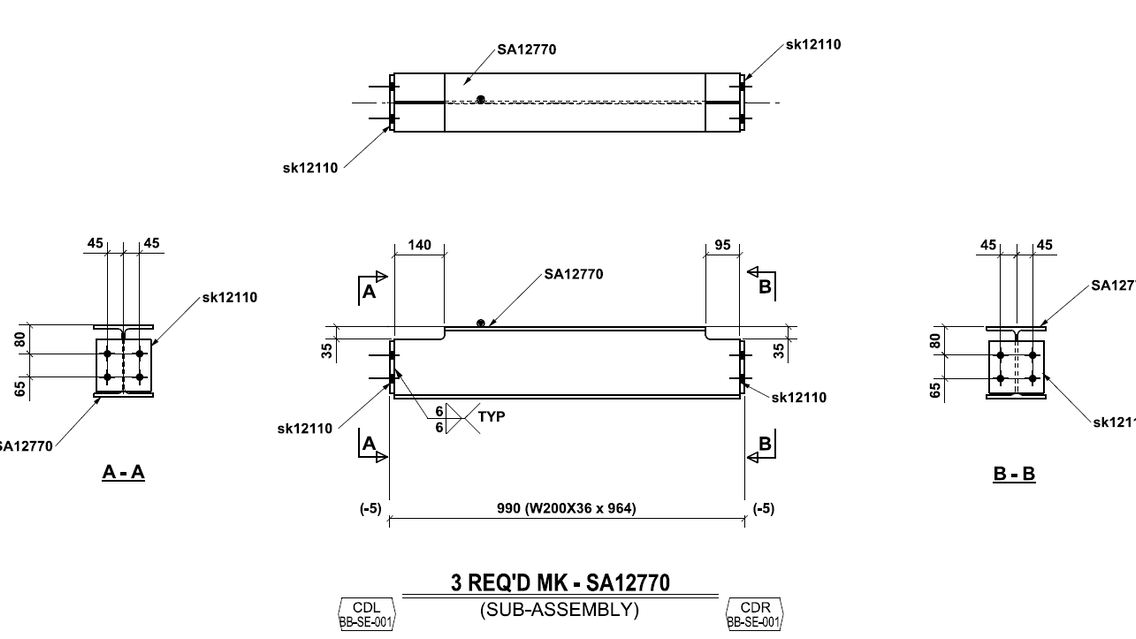

The scope of work for this project included: structural steel, miscellaneous steel, piling, piping, electrical, mechanical, HVAC, concrete, and civil grading. The structural steel portion of the project (including railing, grating, checkered plate, cladding, ladders, and stairs) was completed through the development of the Steel Model Transfer (SMT) process.

This implementation and success of the SMT process was achieved through close collaboration between the Engineer (Fluor) and the Fabricator (Supreme Steel). The transfer of data in this process was made possible through custom software and existing Tekla tools. The consolidation of all information was completed directly within the Tekla Structures environment.