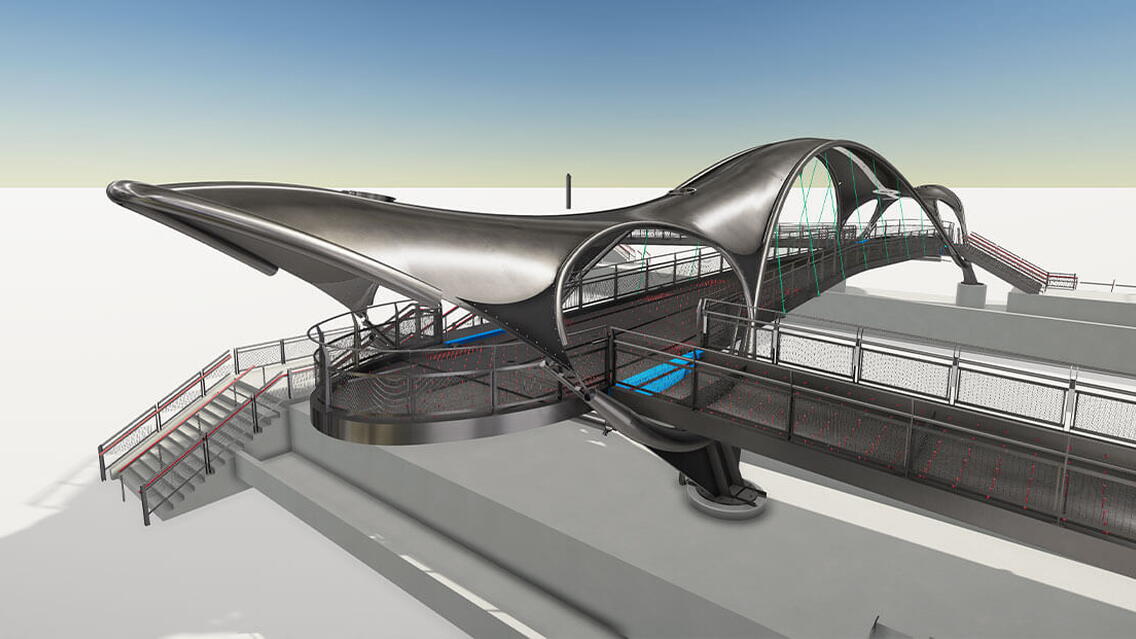

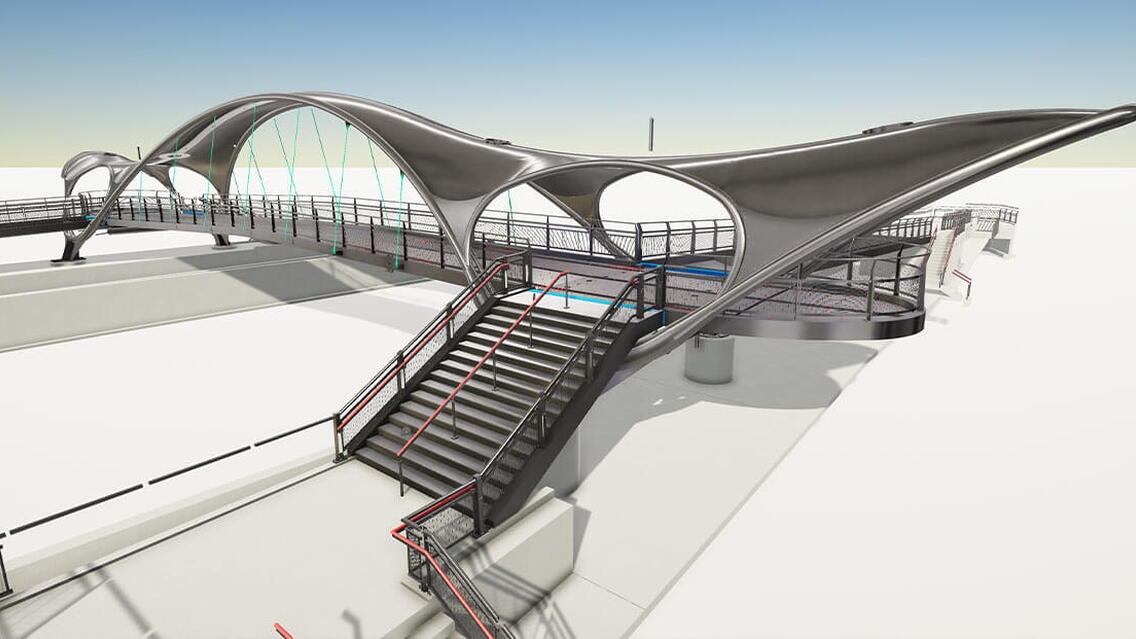

The new footbridge is part of a large highway improvement scheme being carried out on the A63 in central Hull.

The new bridge creates a spectacular gateway into the City whilst forming a critical link for pedestrians and cyclists between the City and the vibrant docklands and marina area. The bridge replaces a very busy controlled pedestrian crossing which became particularly congested at weekends.

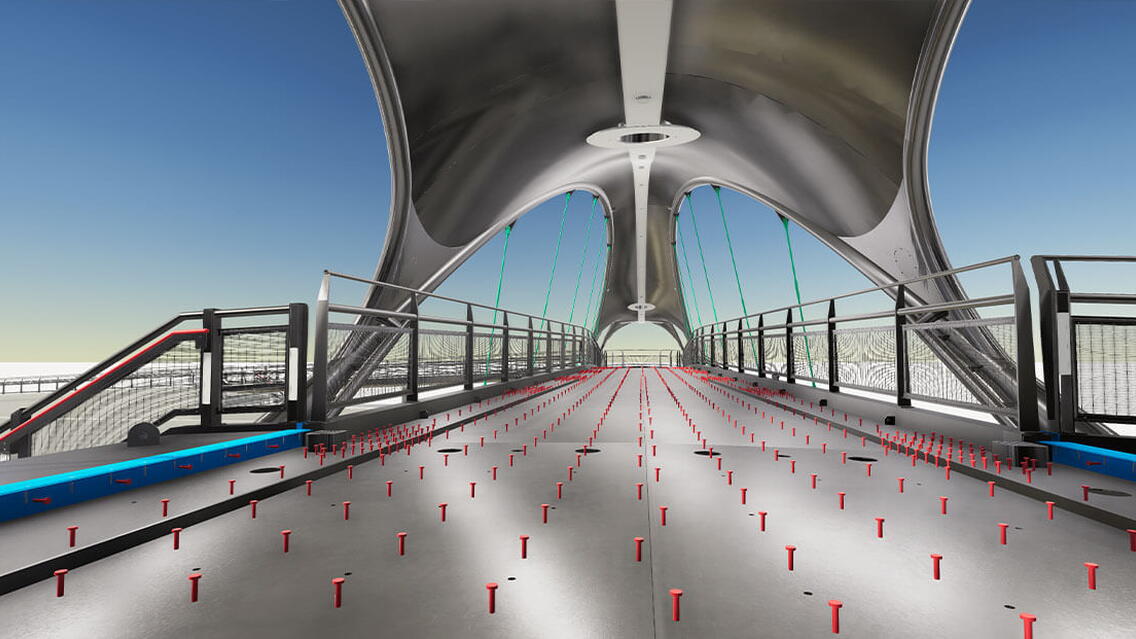

The design of the bridge takes full advantage of the site and provides users with a wide safe crossing with cantilever decks at each end which allows users to rest and enjoy the views. The users experience is further enhanced by the carefully considered hard landscaping which provides terraced seating areas with views across the marina. The A63 is a critical artery through the city and it was essential to minimise the impact on road users.

The team developed a construction strategy that allowed the structure to built off-line in a nearby assembly area and driven into place using mobile transport units. This complex operation was performed safely and efficiently in a very short overnight road closure.

What were the challenges and what made the project successful?

Constructing a major infrastructure project over a busy city highway will always have its challenges. This project was no exception however most of the challenges were to do with planning and timing as the bridge was originally part of a larger highways scheme. It was decided to separate the bridge and let it as a stand alone package. The delivery team worked collaboratively to successfully eliminate construction risks and challenges and the teamwork and attention to detail have resulted in a stunning new landmark for the City of Hull.

What benefits did utilizing BIM and Tekla software bring to the project?

The modelling and drawing certainly had their challenges, particularly the 3-dimensional curved plates and ensuring they were accurate. These elements were defined by the engineer which we were then able to extract their geometry and bring it into Tekla Structures. This geometry was then passed on to our plate bending contractor who refined the engineer’s original setting out to make it smoother in places and then pass this back to ourselves. The interoperability of Tekla Structures was crucial in allowing us to process this information and then relay it onto the drawings for our fabrication shop.

Hull enjoyed one of the first warm days of Spring just after the bridge opened and it was wonderful to see people not just using the bridge to cross the busy A63 but to actually be clearly seen to be enjoying the experience.

The project in numbers

- The scheme consists of a 60m span steel footbridge with a total weight of 140tonnes. In addition access for all is provided by stairs and over metres of ramps.

- The total steel tonnage was 220te.

- The cost for manufacture, assembly and installation of the structures was £2,485,200