The National Children's Hospital will provide world-class medical facility for children and young people from all over Ireland, who have complicated and serious illnesses

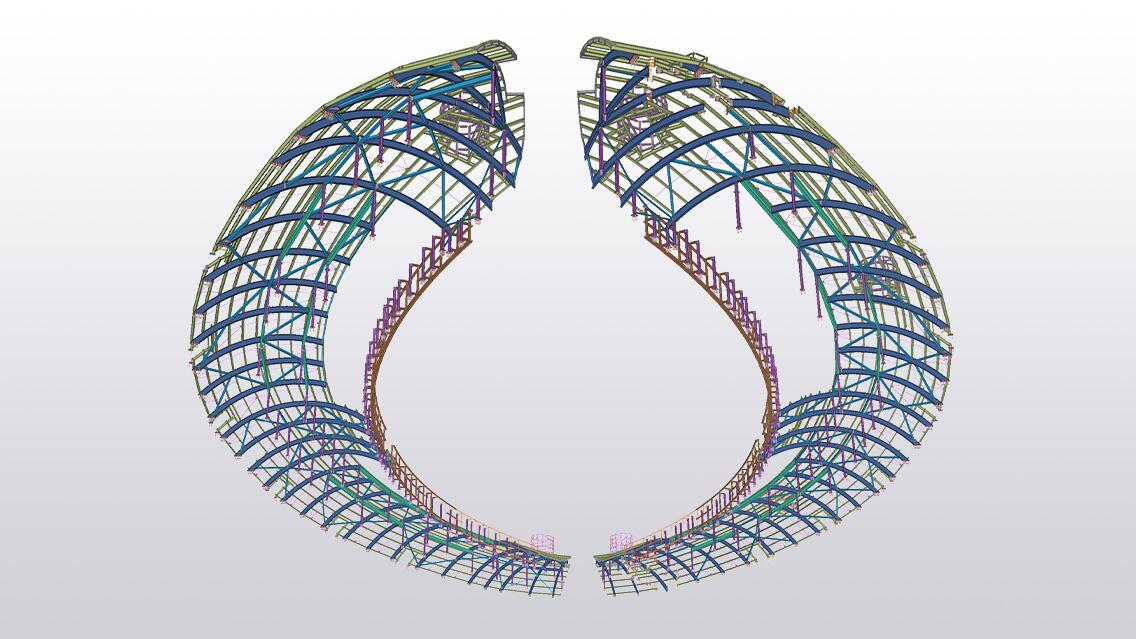

We were asked by Steel Fabricator KH Engineering to undertake the steel detailing for the roof package on the NCH. The oval's form alludes to the architecture of Dublin's best know civic spaces and buildings, most notably the Georgian Squares as well as the nearby Royal Hospital at Kilmainham (Irelands oldest hospital). Once complete, the new hospital will have open view towards Kilmainham and Phoenix Park. The NCH is the largest and most complex and significant capital investment healthcare project undertaken in Ireland, consisting of seven storeys, 6150 rooms and 1000 car park spaces.

Reducing man hours drastically

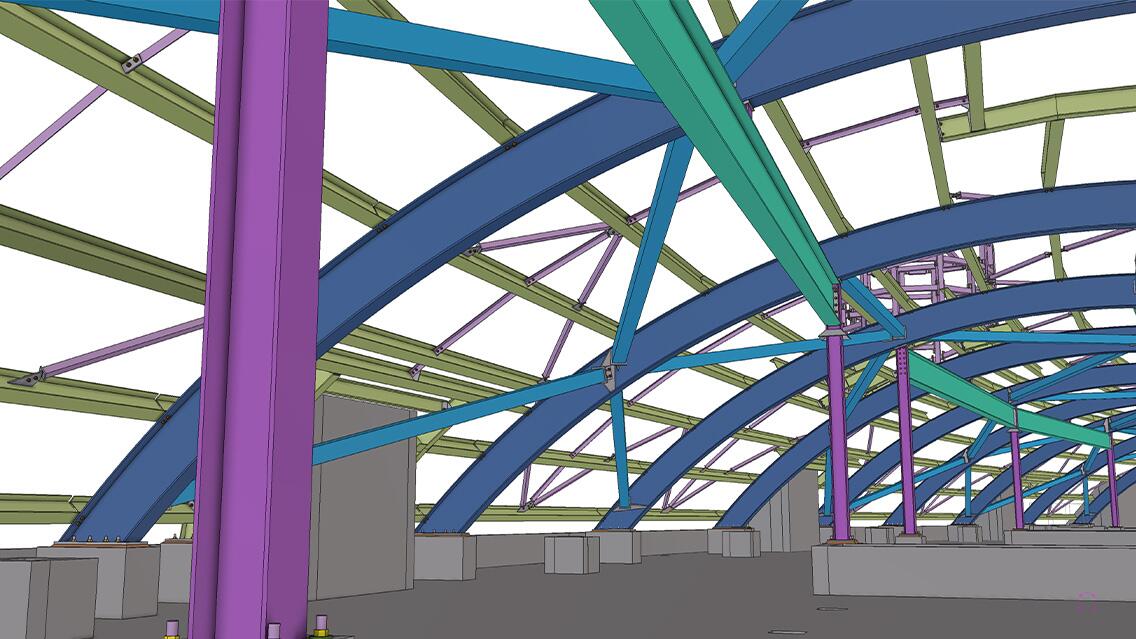

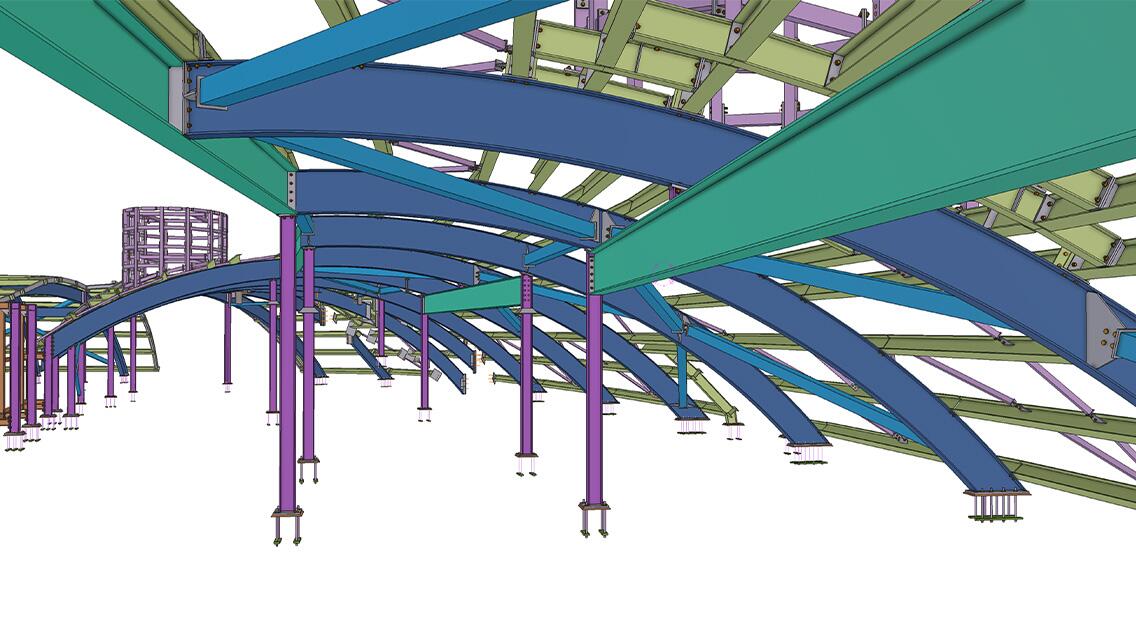

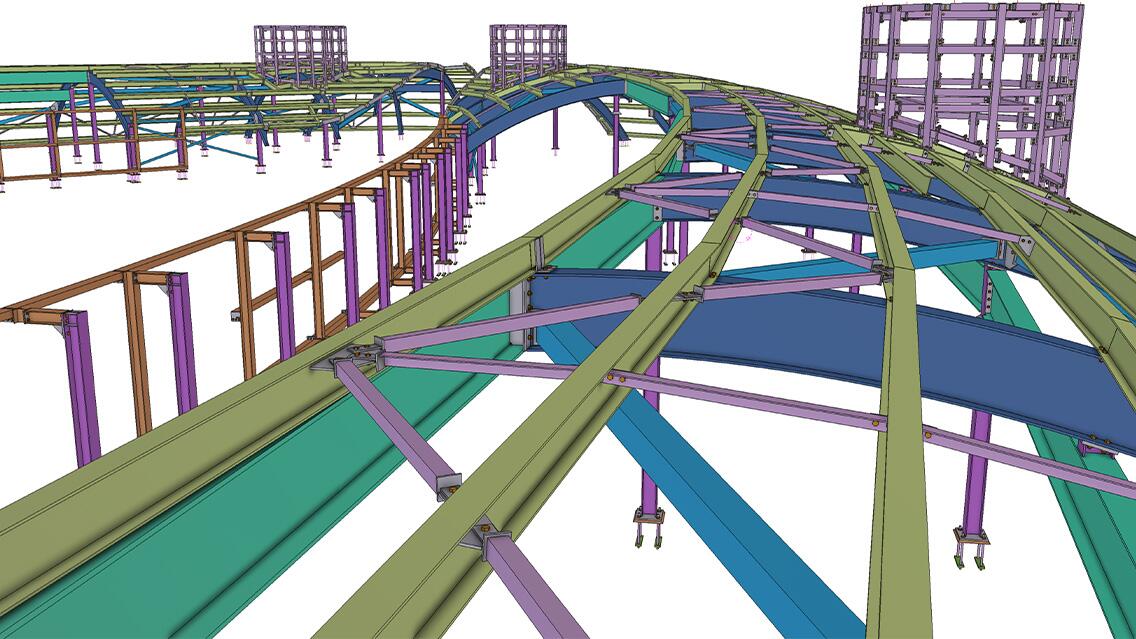

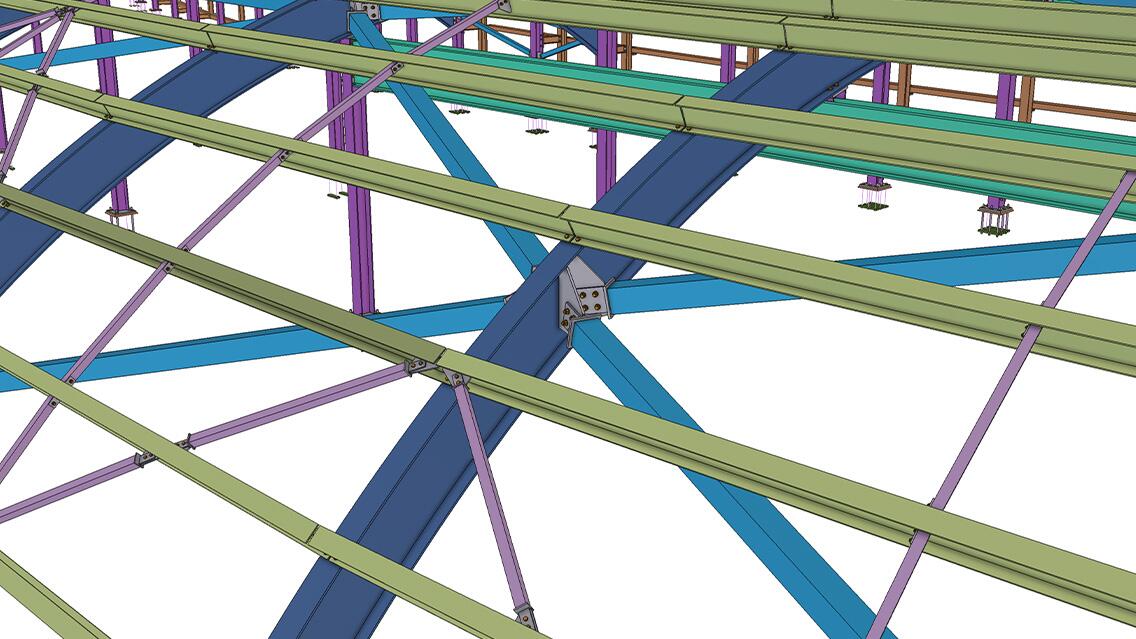

There were many challenging sides to this project, the rafters were curved with the transverse purlins spanning onto the curved rafters creating a faceted framework. We also have steel to concrete connections and due to the geometry the connections were challenging. We imported the site survey data to enable us to set out the concrete cores - which were also sloping, which made the connections even more challenging. All steelwork was galvanized meaning weep holes (along with lifting points) were introduced in all beams and columns, we were able to use components for this workflow reducing man hours drastically. We also had six chimney stacks to accommodate.

Using Trimble Connect, we were able to import all the other design team models giving us an accurate multi-discipline model to work from. We were able to invite everyone we felt would benefit from using Trimble Connect and highlight clashes and suggest changes to the design by tagging design team members using the 'To Do' action tool. This way we could keep a live diary of what actions were required and what actions had been taken. Using Trimble Connect meant we had access to the latest design team models giving a superb coordination tool. The curved rafters were cut in Holland and transported over during Covid. We exported to Strumis when issuing fab packs to our client.

Important points or benefits:

- User defined attribute fields were used to highlight the zones that were worked on site

- The Project was Execution Class 4

- Parts: 25806

- Bolts: 26072

- Assemblies: 13069

- Assembly drawings: 3881

- Single part drawings: 6017

- Tonnes in total: 576