Esquisso aims to apply for the BIM Awards 2024 with the project of the Colombo Shopping Center located in Lisboa, Portugal. The Colombo shopping center is an existing building constructed in 1997, which, due to increasing demand, has opted for significant expansion without interrupting its operations during construction in 2023.

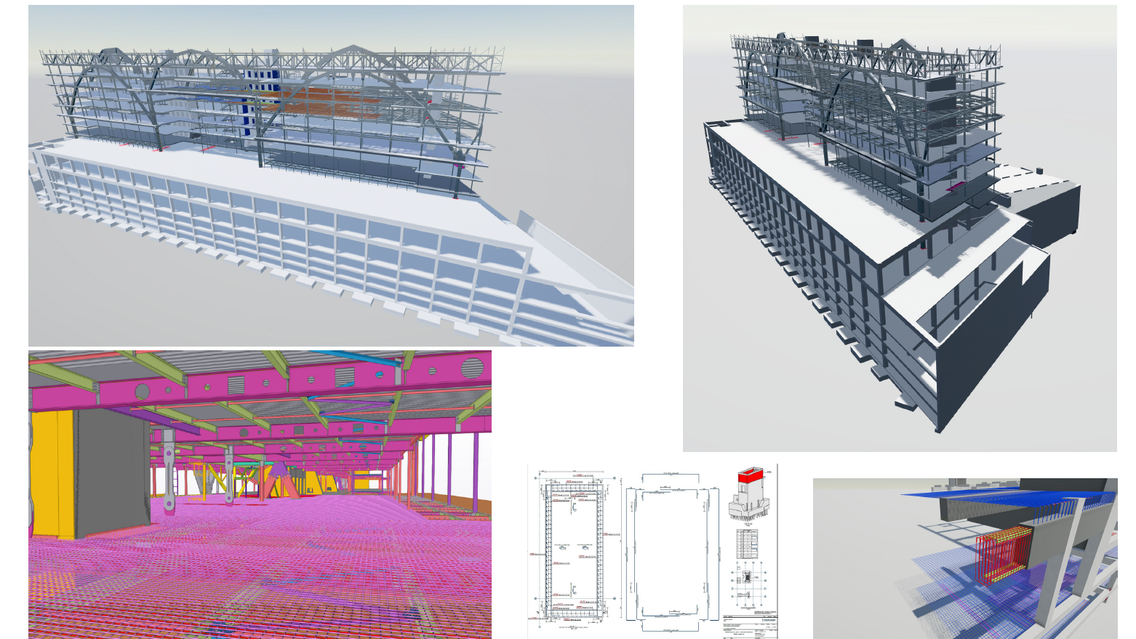

This project involves designing and modeling a new construction within the existing structure, which includes an expansion of 10,968 m2, of which 5040 m² will correspond to office space and the remaining 5928 m² will be part of the parking area.

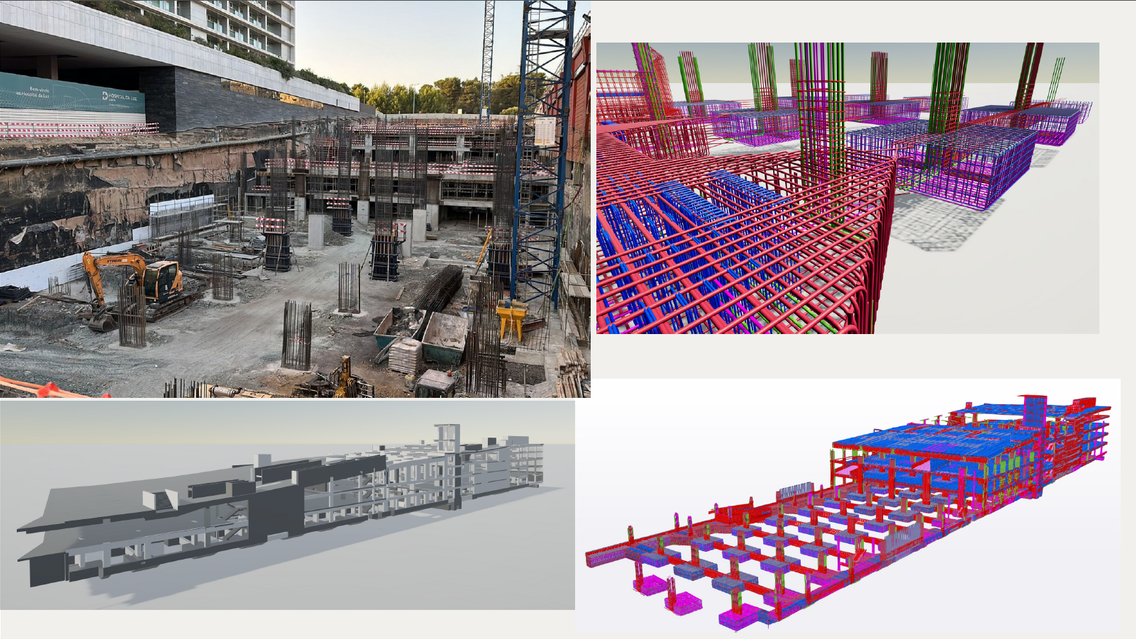

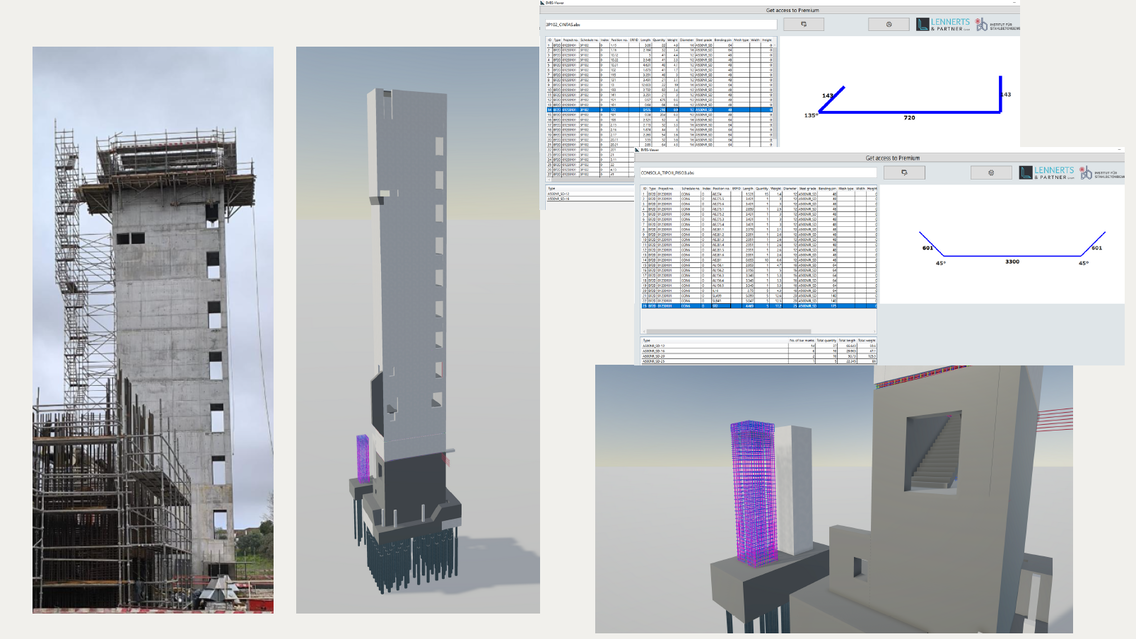

This posed a major challenge for the project, as four cores were constructed to support all upper floors of the new structure without affecting the structural integrity of the existing building. This led to a significant concentration of reinforcement and the need to coordinate the reinforcement of all new structural elements with the foundation and existing structure.

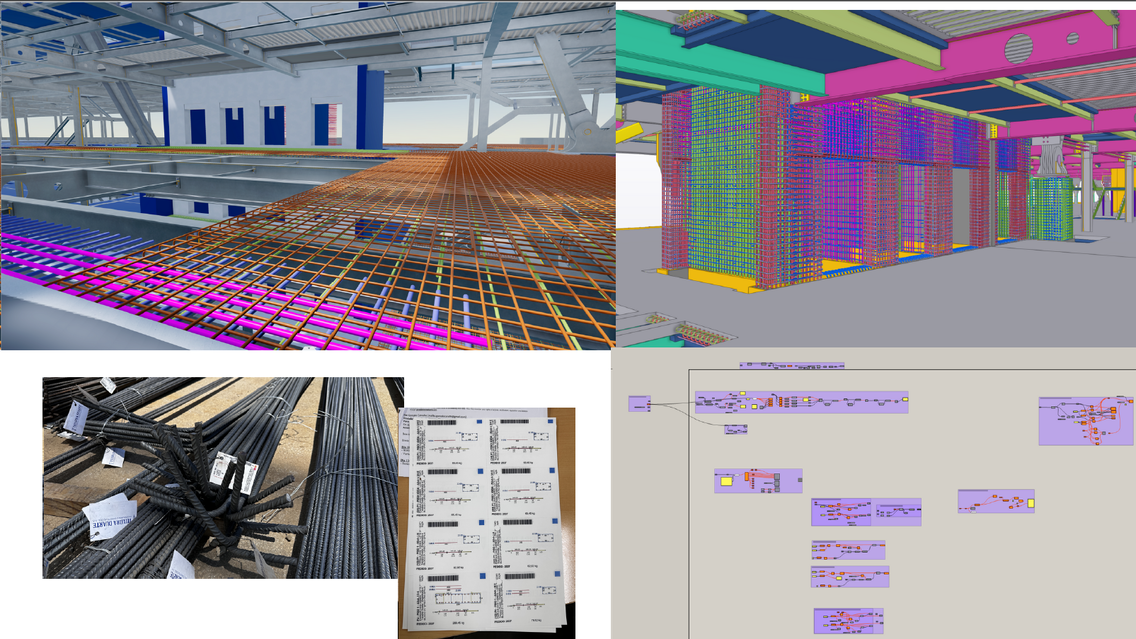

Our team took the use of Tekla Structures software to the next level by integrating it with Rhino and Grasshopper programs, allowing us to develop an application to model slab reinforcement as 2D lines and then transform them into reinforcement steel in Tekla Structures. This integration significantly increased efficiency in modeling these elements. Together with Tekla Structures tools, we managed to model over 3000 tons of reinforcement steel.

With the model developed in Bogotá (Colombia) as described above, files were obtained in BBVS formats, which were imported into the GraphicoPro software for reinforcement steel fabrication. At the reinforcement production center located in Montijo (Portugal), these lists were printed and scanned directly on the steel shaping and cutting machine, optimizing productivity and reducing waste in the manufacturing and assembly process at the construction site located in Lisboa (Portugal), maintaining production traceability throughout the project execution.

Finally, Trimble Connect was used for project management, overcoming language barriers, different time zones, and locations to achieve effective and precise communication. Through this tool, our team generated production batches with on-site support, assigned information to elements for order generation, and controlled construction progress in real-time with the Trimble Connect organizer.