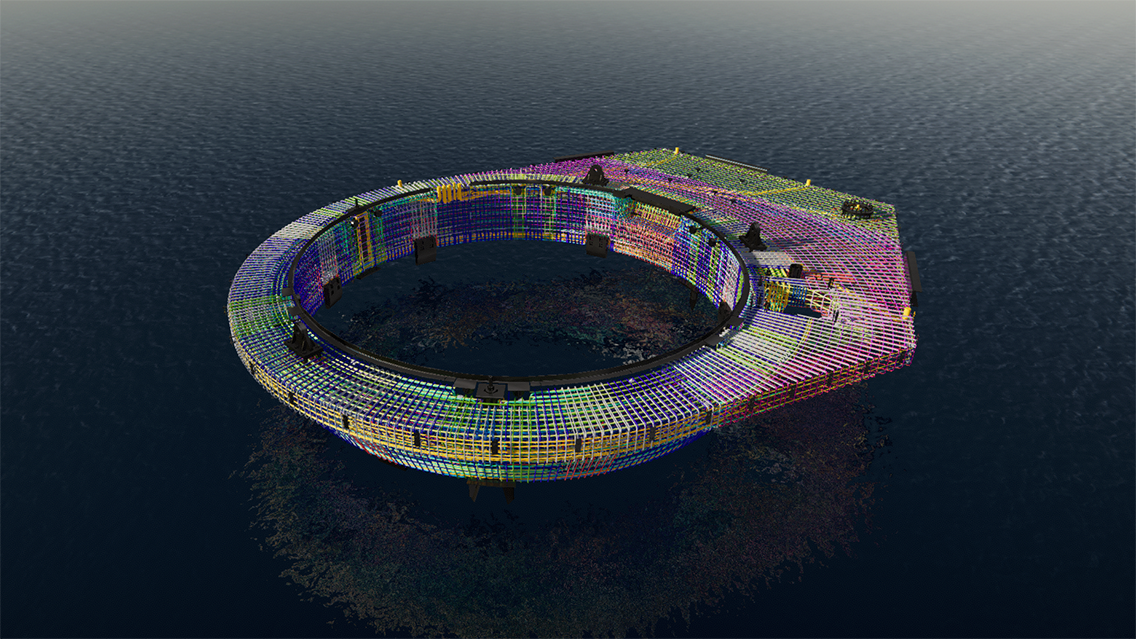

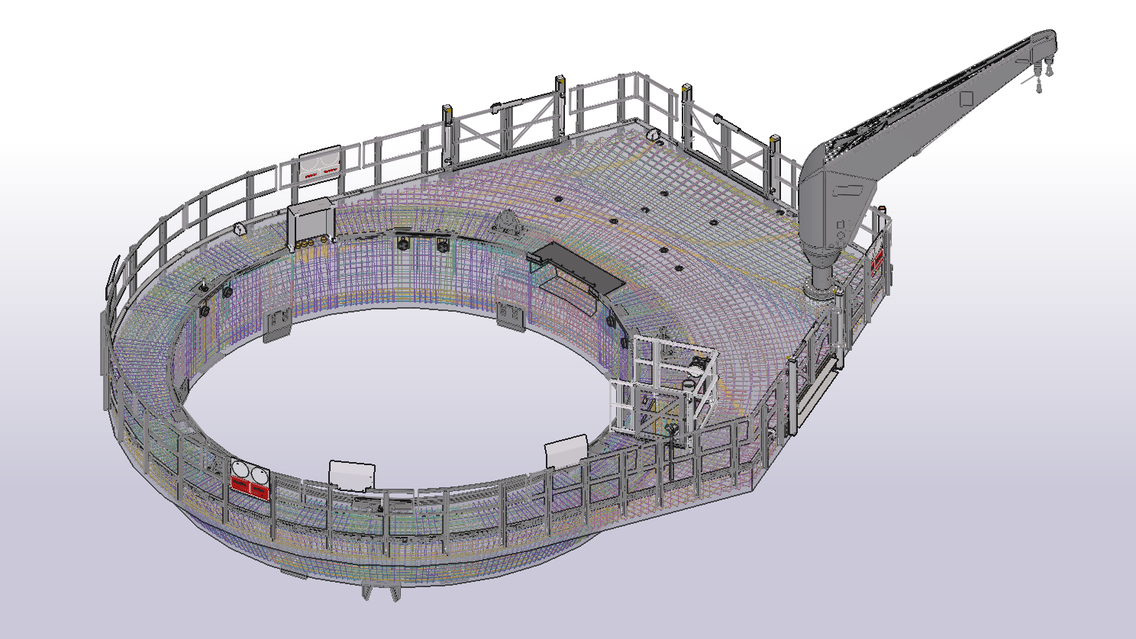

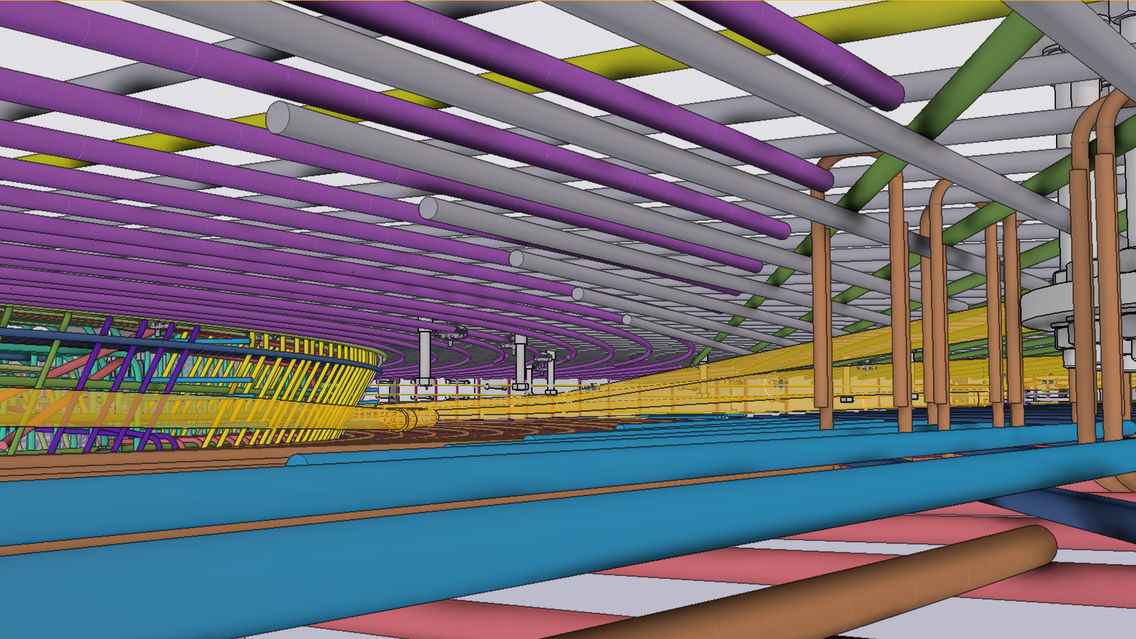

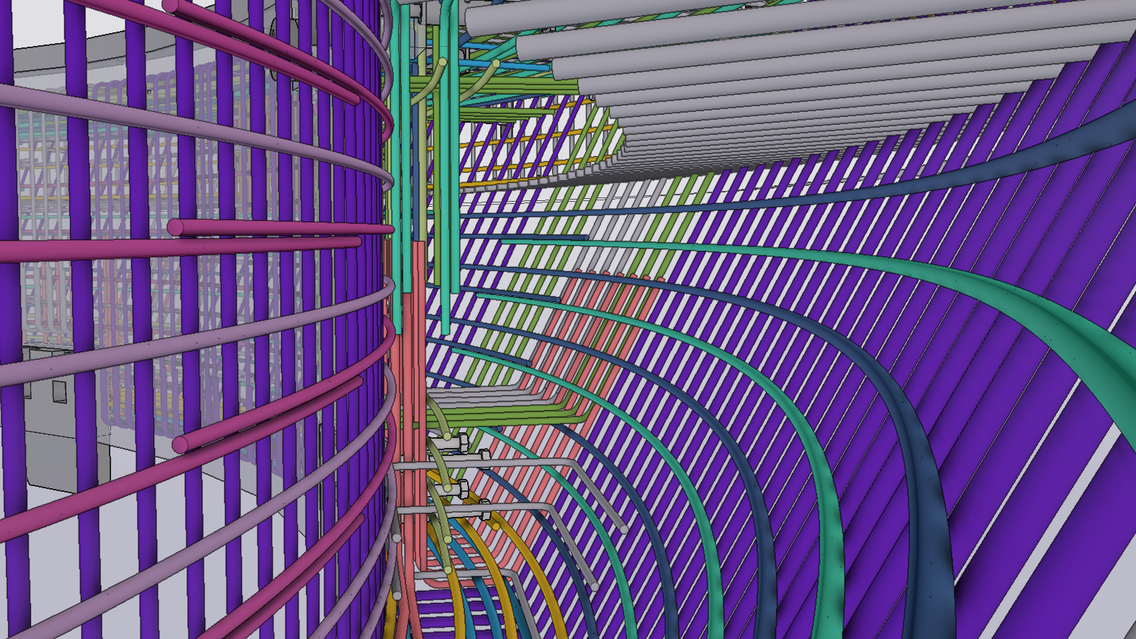

Design of concrete platforms for a large offshore wind farm located in the North Sea. The task consists of producing a 3D model of reinforcement and cable ducts based on the platform's complex geometry. The work included analyzing and resolving all collisions and preparing detailed reinforcement drawings. Moreover, our model was a basis for a more precise insert arrangement. Modeling and coordination works were carried out using Tekla Structures and Trimble Connect.

Challenges and what made the project successful

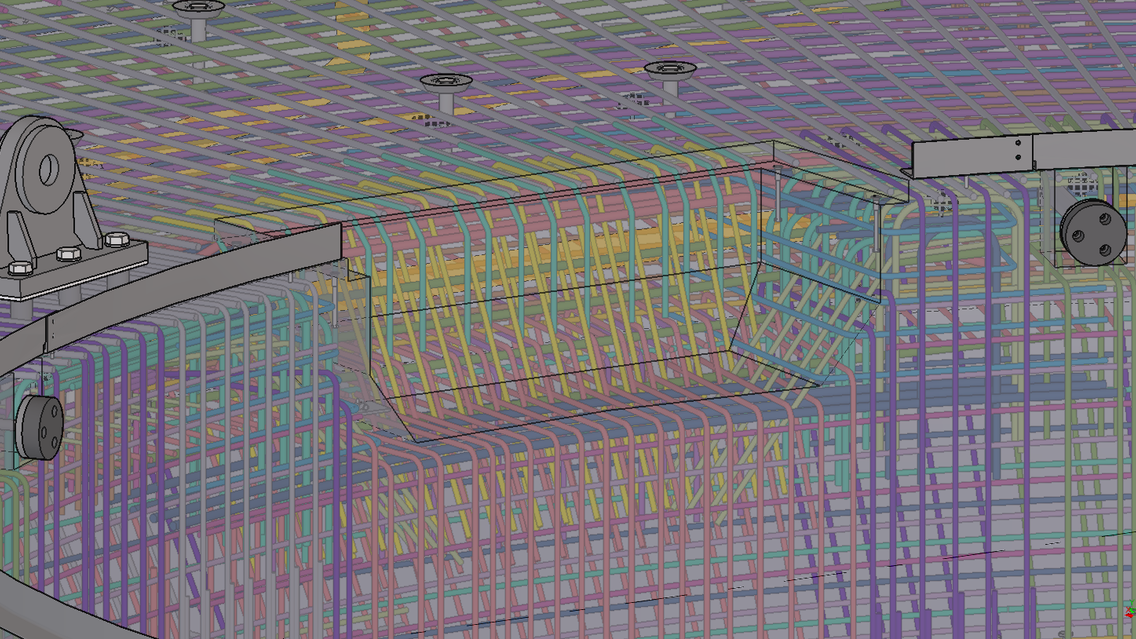

The challenges were highly complex radial geometry and a large amount of reinforcement that had to be distributed without collisions. Another challenge was preparing a model with a high level of detail that could be effectively used during fabrication to correctly place all reinforcement inside the formwork and speed up the fabrication process.

Most of the inserts were imported into the model as a reference, and the remaining ones were modeled using items. High skills in reinforcement modeling allowed us to avoid nearly 100% of collisions, which is crucial to the prefabrication process. Participating in pro-ecological projects is very important to our company, and we strive to focus on similar projects. Thanks to advanced information exchange, we collaborated with the mechanical engineering industry.

Summary

We are most proud of the advanced and effective information exchange with the client and team members using IFC/STP models and the Trimble Connect platform, as we consider this part to be the most important for collaboration. We also value the impact of positive ecological change in energy sourcing. Due to the highly complex nature of the model, the task was associated with many difficulties, and successfully completing it fills us with pride.

- Diameter of the inner ring – 8.2 m

- Ring beam width – 1.2 m

- Ring beam height – 1.6 m

- Volume of concrete – 51 m3

- Weight of steel – 10.3 t

- Weight of the platform (concrete, reinforcement, additional elements: pipes, earthing clamps) – ~ 135 t