Project description

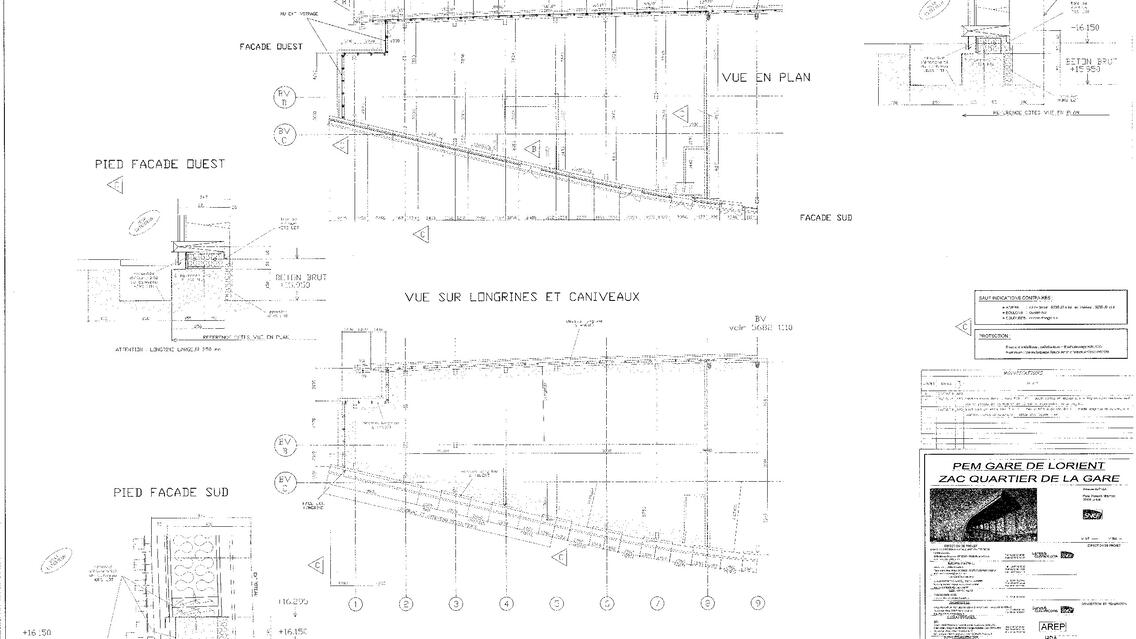

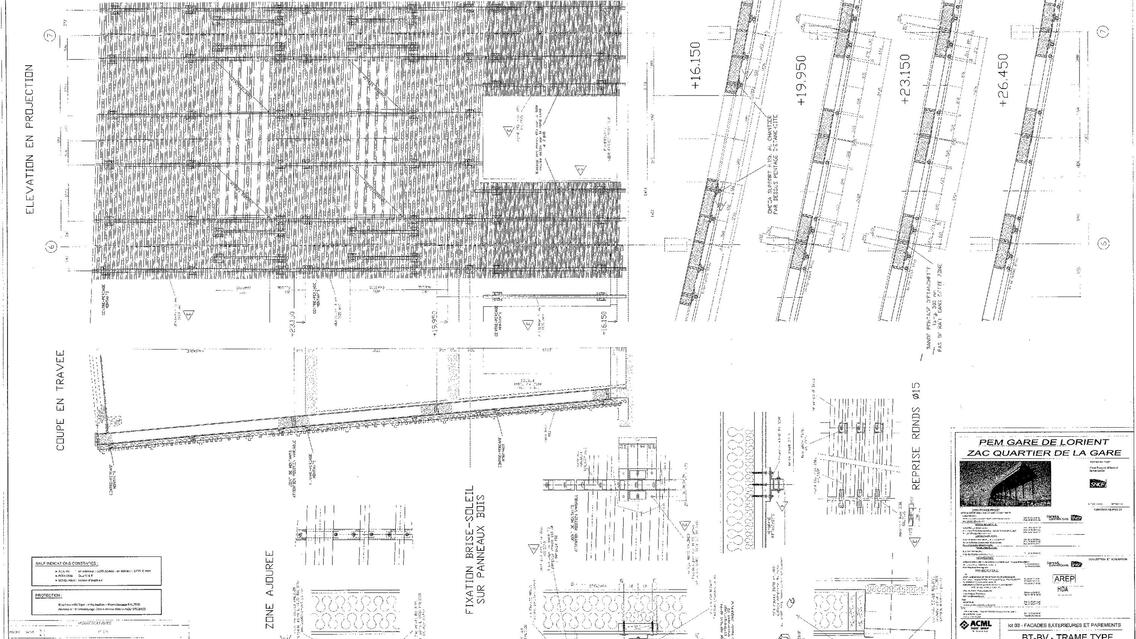

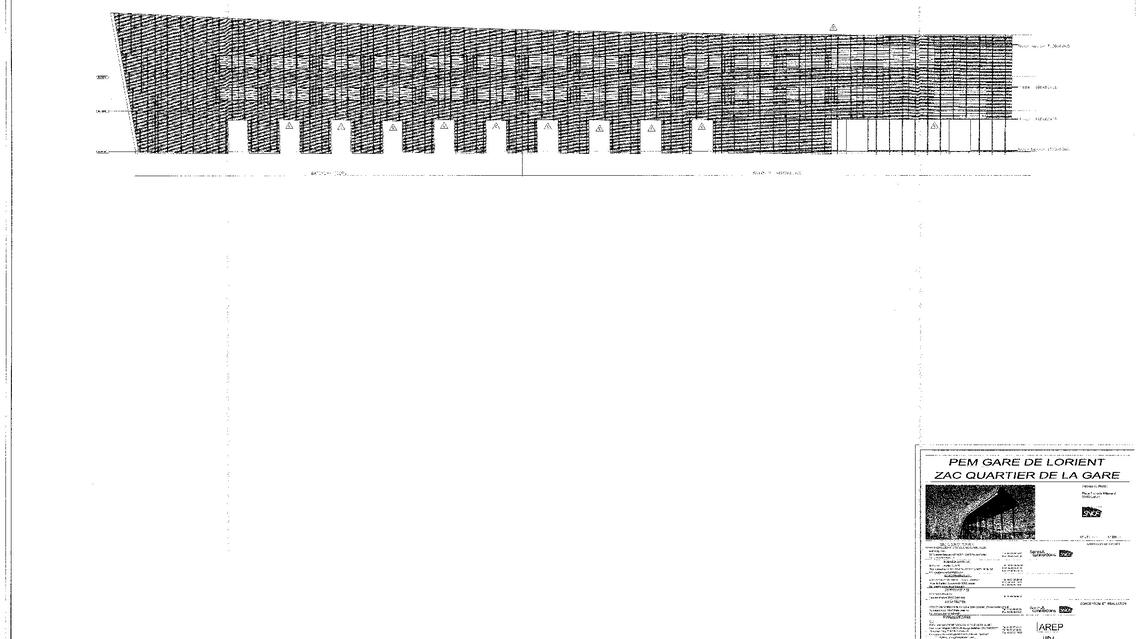

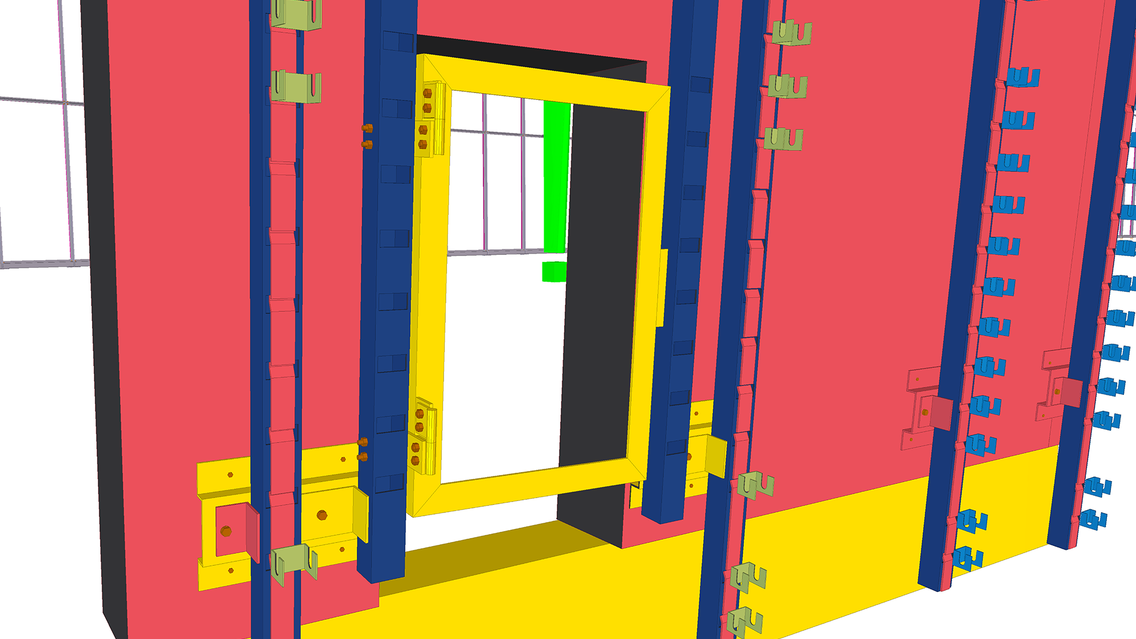

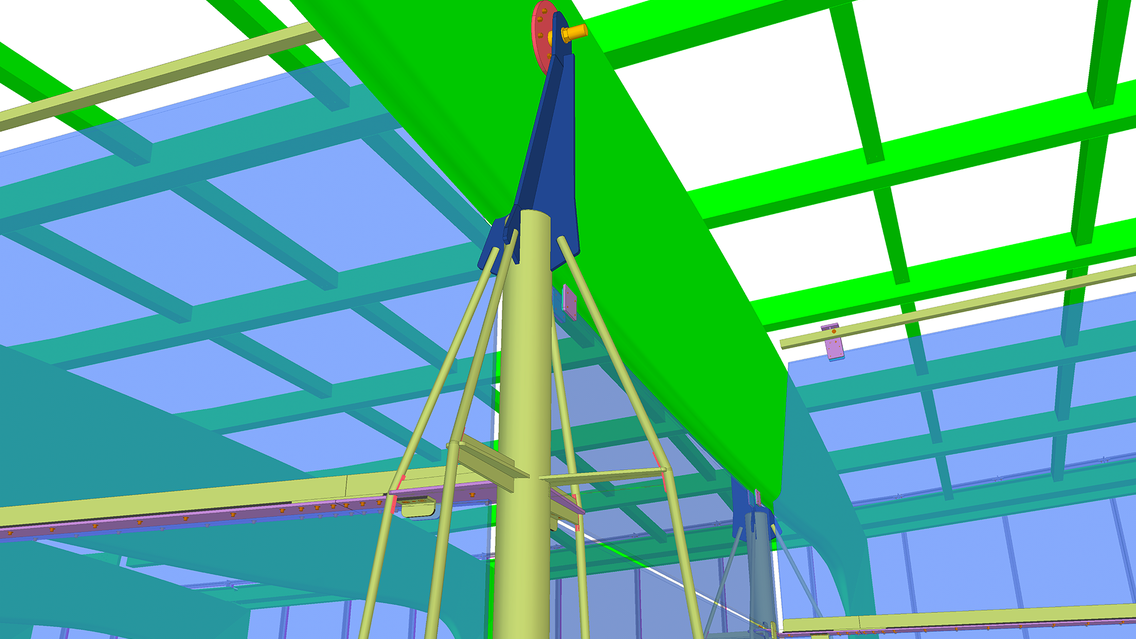

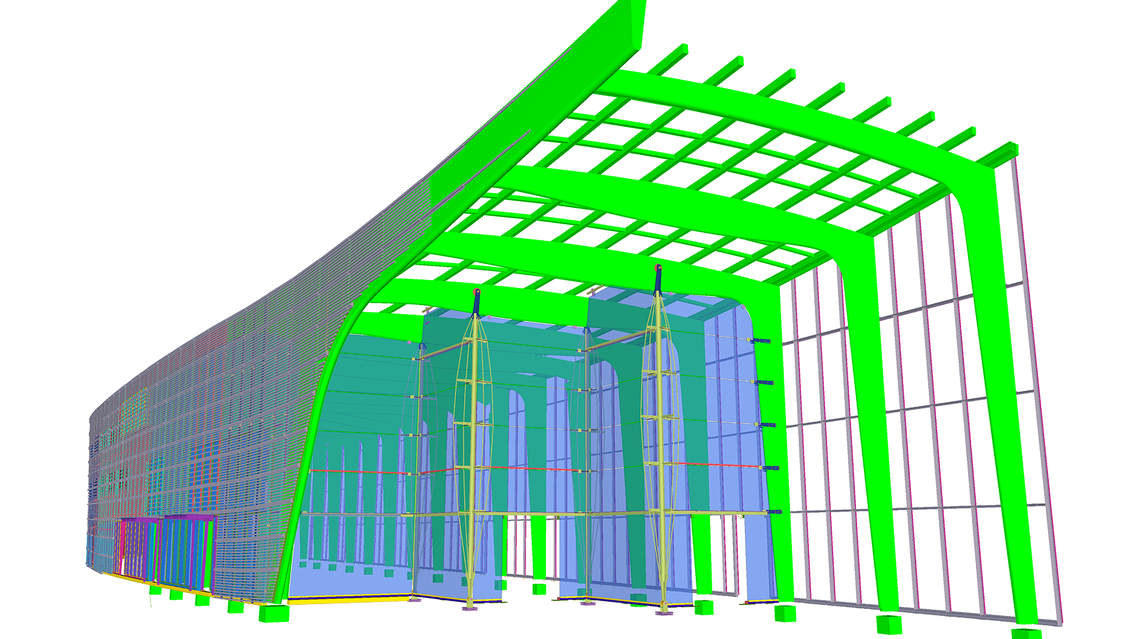

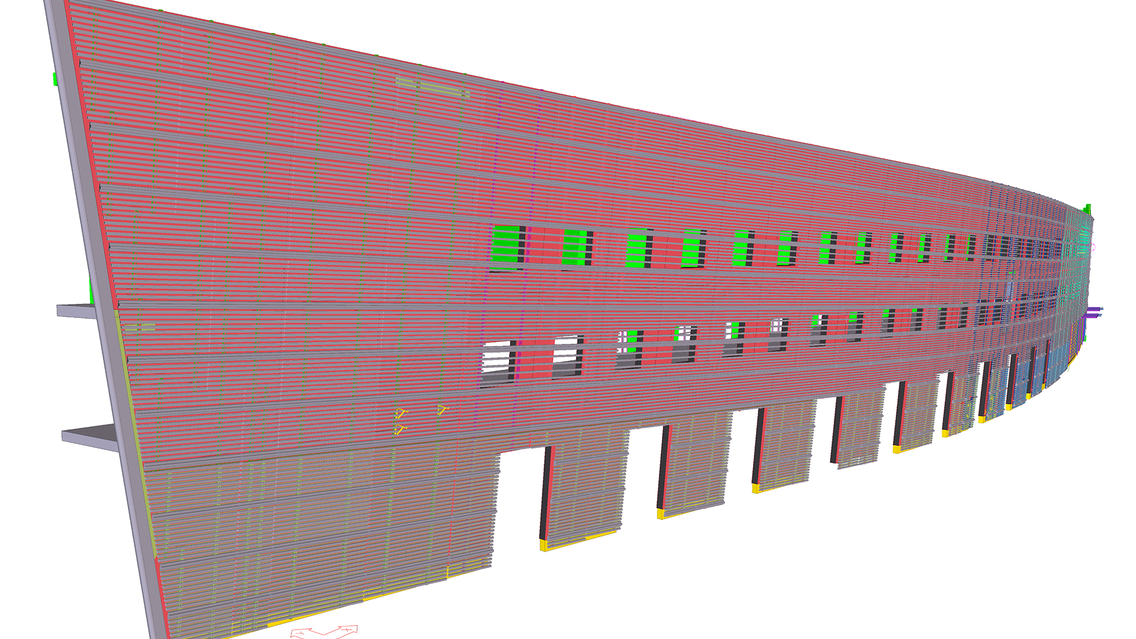

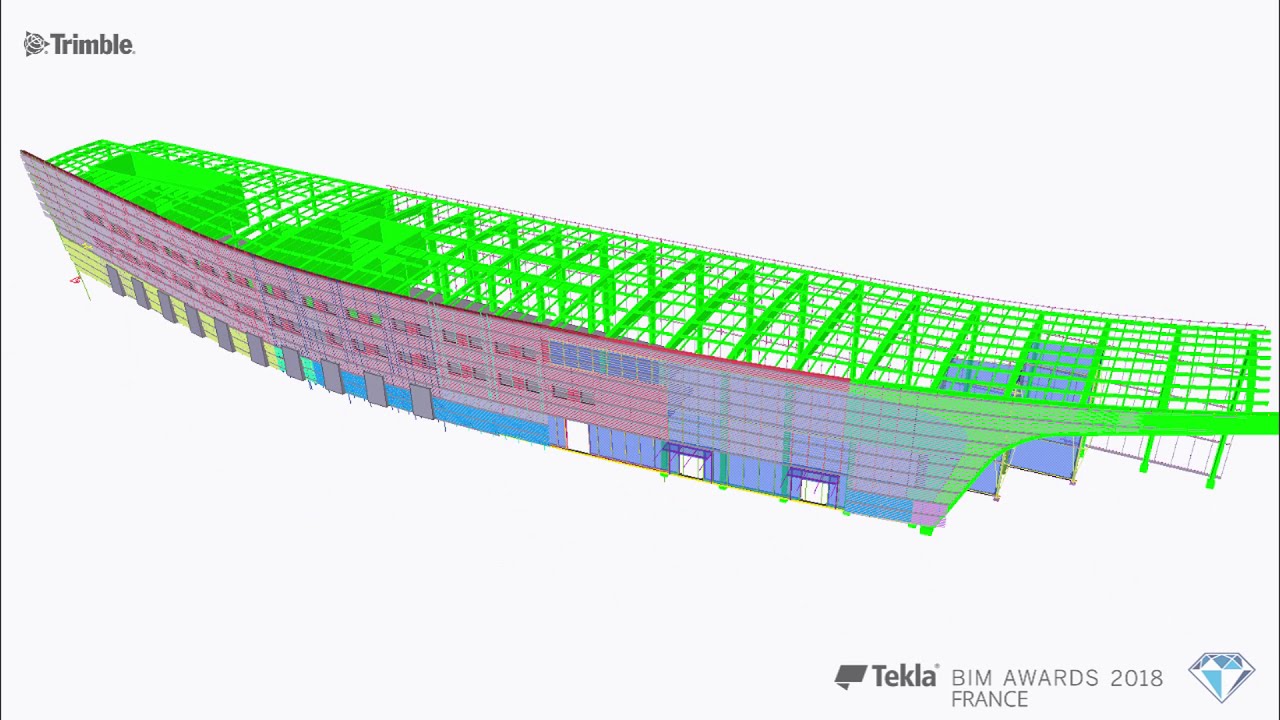

Construction of the SNCF station and a Multimodal Exchange Department (MED) at LORIENT. A public usage building. Initial design stage in 2015 for delivery on May 12, 2017. ACML was responsible for the macro lot "façade" composed of the metallic frame for the glass exteriors, wooden exteriors (MOB), the maintenance platforms, and the UHPC shading devices. The exteriors in this project connected on the one hand to the very stiff West portion made from concrete and the very flexible East portion made with a bonded laminated wood frame that presents a very large cantilever. The alliance of various materials at the level of the South façade (UHPC, wood, glass, steel, etc.) required the implementation of an ATEx. A building site notice was also created at the level of the East glass exterior.

What were the challenges encountered that contributed to the project's success?

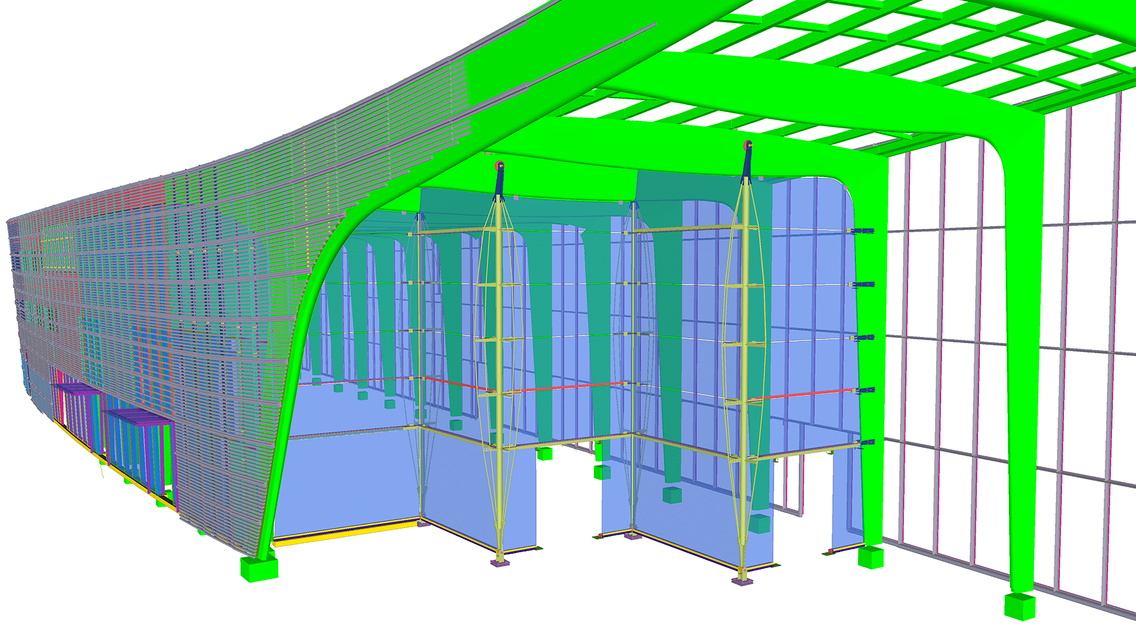

- Integration of the East exterior cut from a metal structure and large glass volumes at the end of the cantilever of the wooden frame. The movements of the wooden frame are relatively important, taking into account the eaves and the bending of the building, while the exterior that we created only tolerates a few millimeters of movement. Therefore we had specific assemblies implemented enabling the expansion and some assemblies without give.

- Integrate very different components and create the synthesis with them: external wood MOB panel, UHPC sun shade, metal frame, steel curtain wall.

- Modeling the UHPC sun shades taking into account the complex geometry of the South exterior. These are very different. We were able to find geometric rules to group these together in a family.

What benefits did BIM and Tekla Structures provide to you?

Tekla enabled us to work with our partners through IFC file exchanges and to retrieve the wood frame model. The synthesis was simplified thanks to BIM, and we were able to implement an exterior with the sub-trades whose tolerances are about a centimeter with glass components that require millimetric precision. We were able to integrate the 3D statement from the surveyor directly in Tekla and accurately validated the support.