The Pidekso Dam Project is one of the National Strategic Projects (PSN) located in Pidekso. Wonogiri, Central Java. This project has the lowest contract value among the Balai Besar River Basin Dam (BBWS) and Bengawan Solo projects.

Even so, this dam can handle more than 25 million cubic meters and has the widest benefit area drawn by other Bengawan Solo BBWS dam projects.

The Pidekso Dam Project is designed to increase the fulfillment of basic water needs by around 300 liters/second, increase the intensity of planting in an agricultural area of 1500 ha, control floods and increase tourism to improve people's wellbeing.

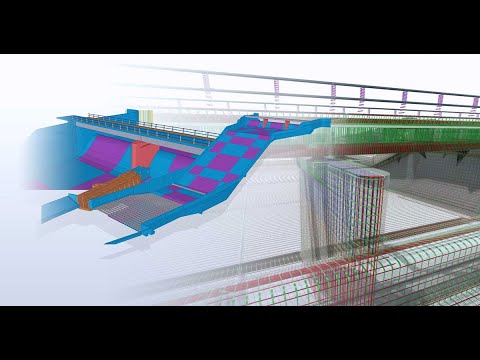

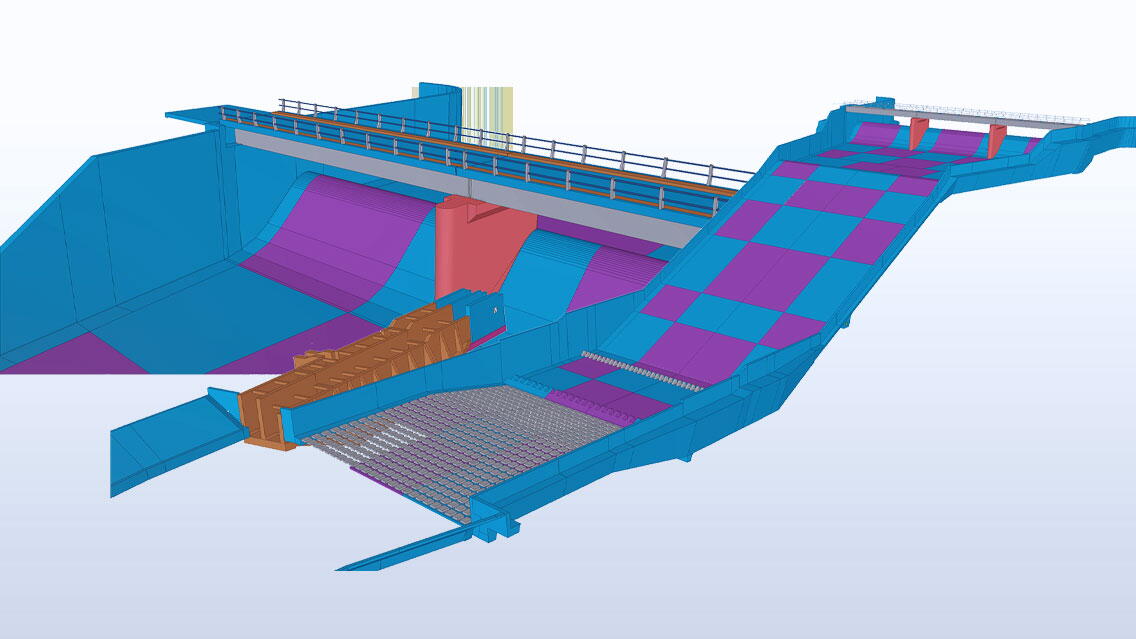

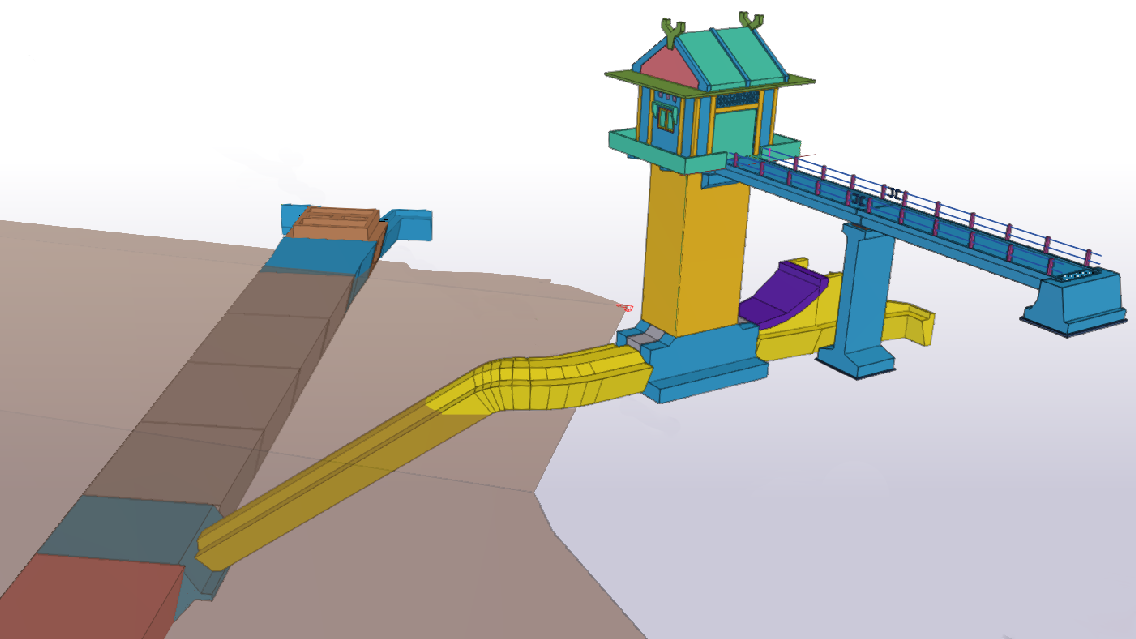

This project has various work items, including earthworks, concrete structures, and mechanical and hydromechanical works. These works require accurate designs, plans, work plans, and monitoring processes.

It is essential to have good technology and an integrated system between components/work zones to avoid planning discrepancies. It is crucial to identify clashes/clashes from the first stage and to monitor the suitability of the plan work implementation in the field to achieve this.

Technical Challenges & Success Factors

During the preparation period, until the construction process was running, the PT PP (Persero) Tbk Team, Infrastructure Division 2, as the main implementing contractor, encountered many obstacles.

Beginning with social constraints, designs that are not following field conditions, as well as many other aspects, have an influence on the smooth implementation of the construction process.

During the initial survey of the dam site, contractors were faced with mass protests against this project. The protest was due to a lack of knowledge about the benefits of the Pidekso Dam for the surrounding residents and stopped us from being able to send a survey team to collect data.

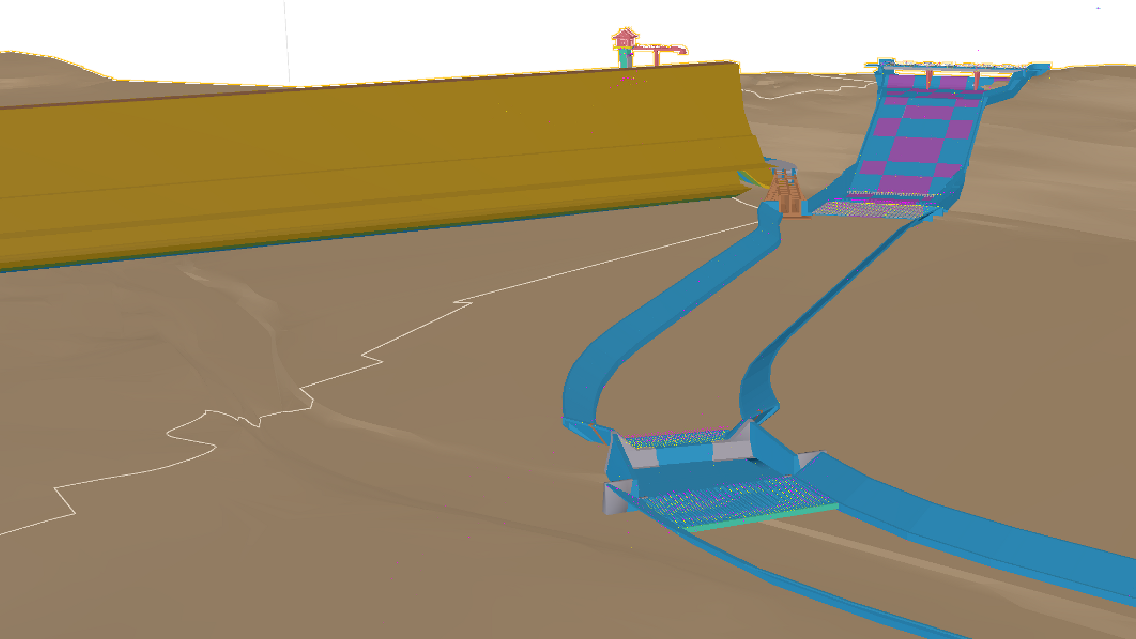

However, by integrating drone photogrammetry and BIM technology, surveys can be carried out effectively and efficiently without disturbing residents around the planned location of the Pidekso Dam. Along with the land acquisition process, the implementation of BIM and the use of smart technology can accelerate the measurement process, where precise and accurate survey data on existing conditions (MC-0) is obtained first.

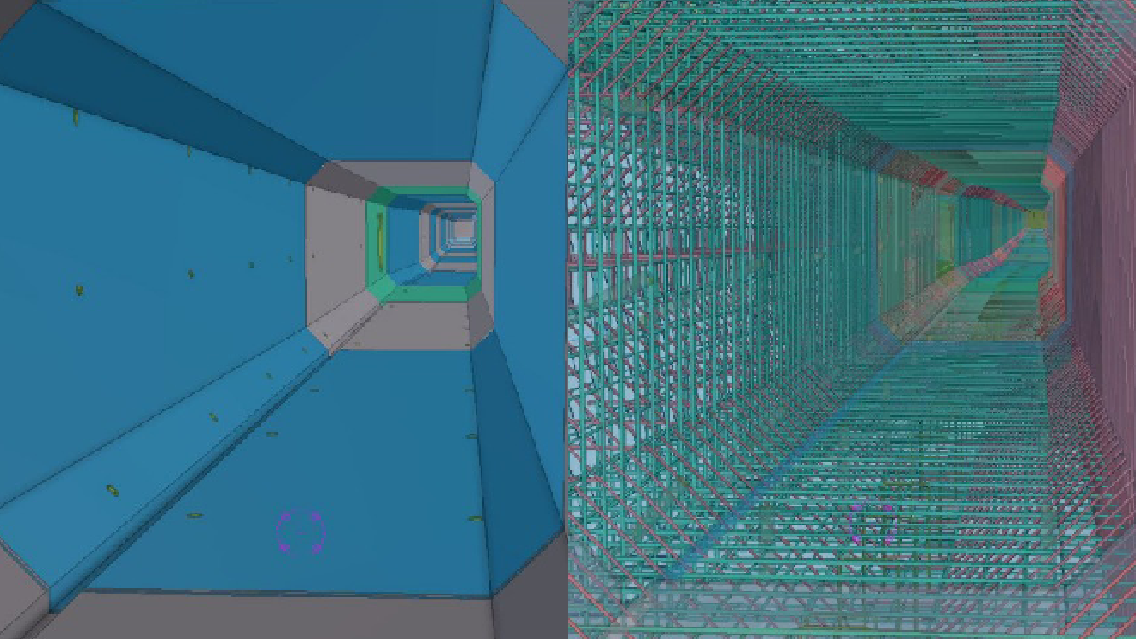

Tekla Structures provides excellent benefits in accelerating project implementation. It makes the project shop drawing production much faster. Without Tekla Structures, drawing production can take around seven days.

With Tekla Structures, the process takes just four days with an additional drafter efficiency of 1 person reduced. Using Tekla Structures speed up the calculation of the volume of work (quantity take off) from the original seven days to 3 days. Besides that, the application of pour management also greatly benefits in reducing waste material (iron and concrete). The average waste material plan is 5%, and with the application of BIM, it can be optimized to be 3%.

The application of smart technology also provides great benefits for project implementation. Typical island clusters in Indonesia are located at the meeting point between plates and volcanic ranges, better known as the ring of fires. This results in the formation of pyroclastic layers in the soil structure. In the implementation of the Pidekso Dam, Geoelectric technology is implemented to determine the condition of the subsoil in the area of the Pidekso Dam building plan.

The feared challenge occurred when a pyroclastic layer was found in the soil layer below the planned location of the dam body. With the Geoelectric method, geological condition data is obtained as a whole and provides an early indication of the presence of this pyroclastic layer so that we can determine the appropriate treatment/implementation method in the area.

Implementing BIM and Smart Technologies, especially Trimble technology, has greatly contributed to this project. Collaboration and integration between BIM software lead the project to achieve its vision in a remarkable way. This project was completed 1.5 years earlier than the initial project completion target with impressive quality and good work safety.

Several Trimble products implemented in the Pidekso Dam construction project include:

- Tekla Structures

- Trimble Connect

- Trimble Laser Scanner SX 104

- Trimble Business Center

Apri Setiawan, GM of Dam Operations Infrastructure Division 2, said that implementing BIM and using smart technology provides many benefits and conveniences in project construction implementation.

"This project has gone through a tough initial stage due to technical and non-technical problems. But, in the end, we were able to get through it and generate various benefits and profits for the company," said Apri Setiawan. He further explained some of the benefits that were achieved and exceeded the company's expectations, including the following:

- Faster completion target

- Save material wastage

- Minimize rework

- Get a good product

- Zero accident

- Maximizing natural resources

"This project makes good use of the collaboration and integration of BIM Technology and other digital platforms to make the Pidekso Dam a champion in all aspects of the construction phase," closed Apri Setiawan when met in his office at the PP Plaza Building.