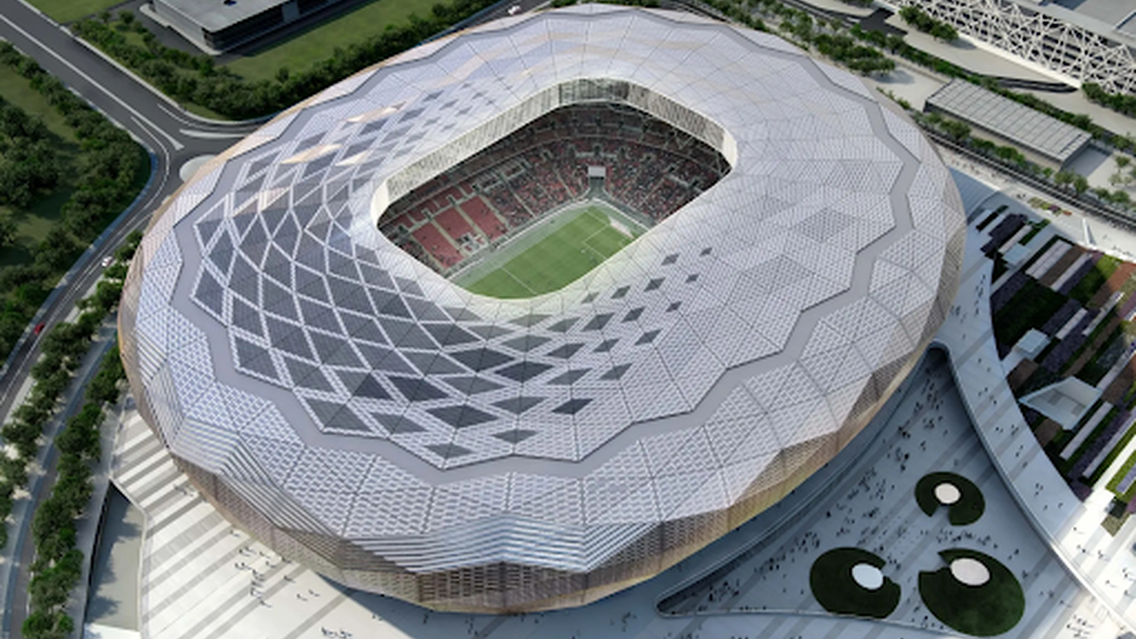

Qatar Foundation Stadium is one of the 2022 World Cup venues and is designed to accommodate 44,000 people

Qatar Foundation Stadium (QFS) is located in Doha, which is the capital of Qatar.

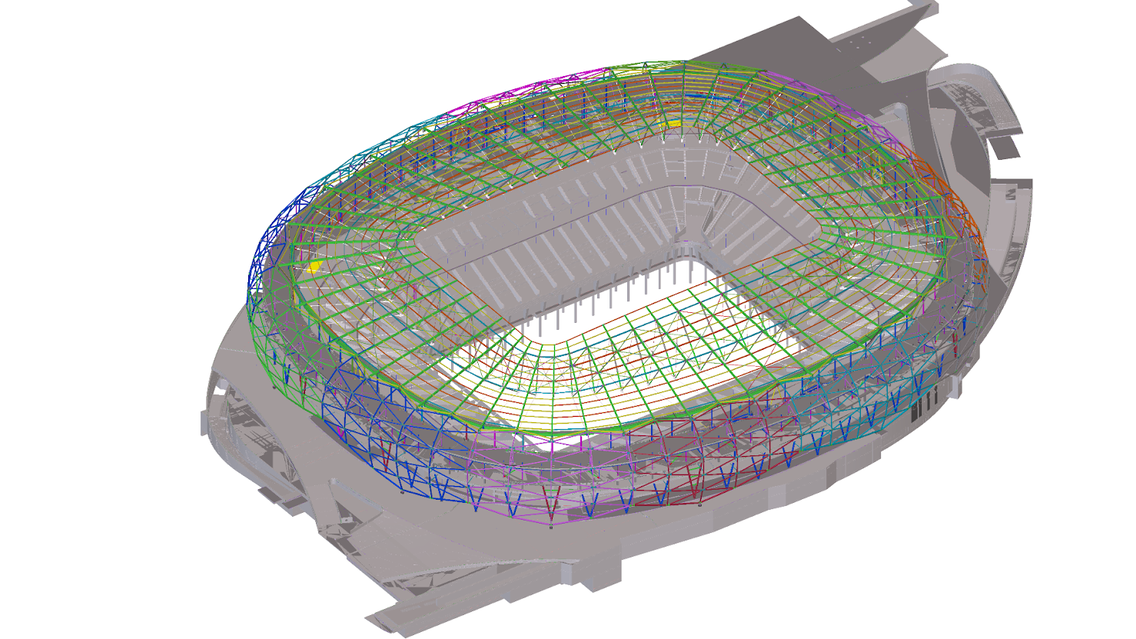

It is one of the 2022 World Cup venues and is designed to accommodate 44,000 people. The structural form of the project is a bowl-shaped concrete stand + spoke-type suspension steel roof, which draws inspiration from Islamic architectural features. Both indoor and outdoor are covered with translucent triangular plates, and the color and pattern can be changed according to the change of sun orientation and artificial lighting.

Difficulties & Challenges

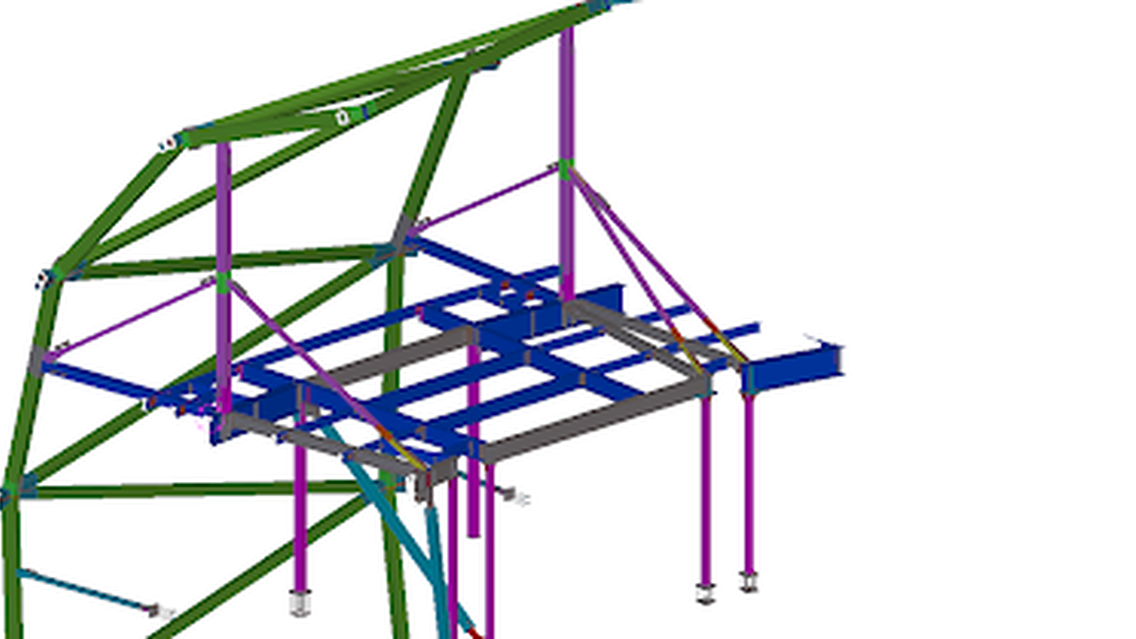

- The facade on the outer surface of the gymnasium needs to be completely smooth and the difference at the junction must not exceed 1mm.

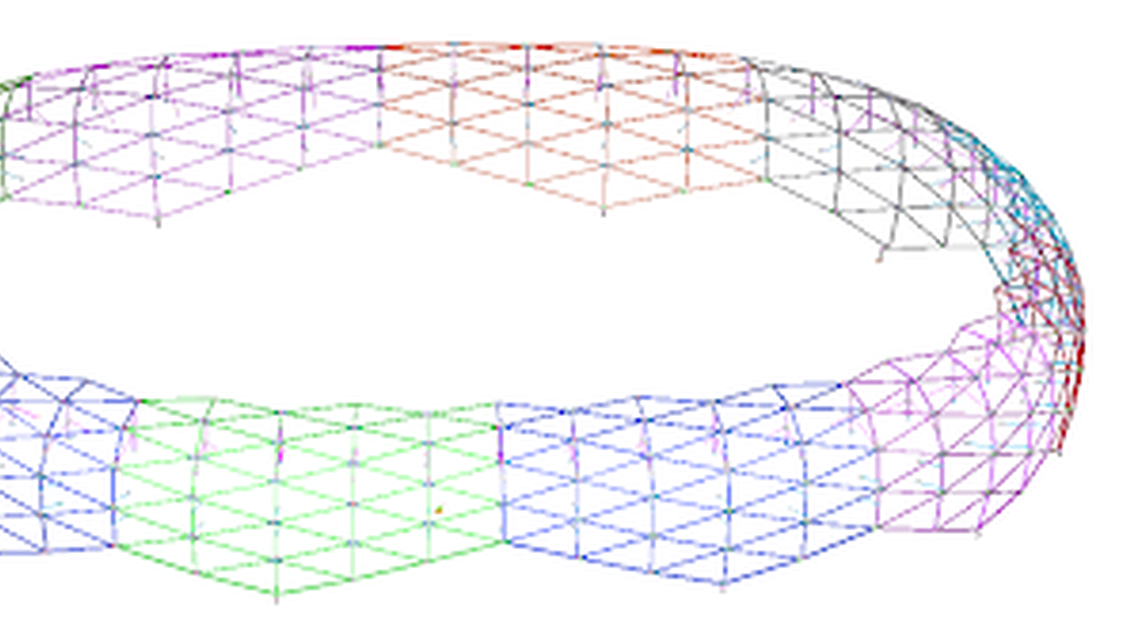

- The support bars on the outer surface of the gymnasium need to be bisected at the angles of two adjacent triangular surfaces, and the directions of each support bar are different.

- Two systems are needed for the pressure ring: pre-arch state processing system and a final forming system.

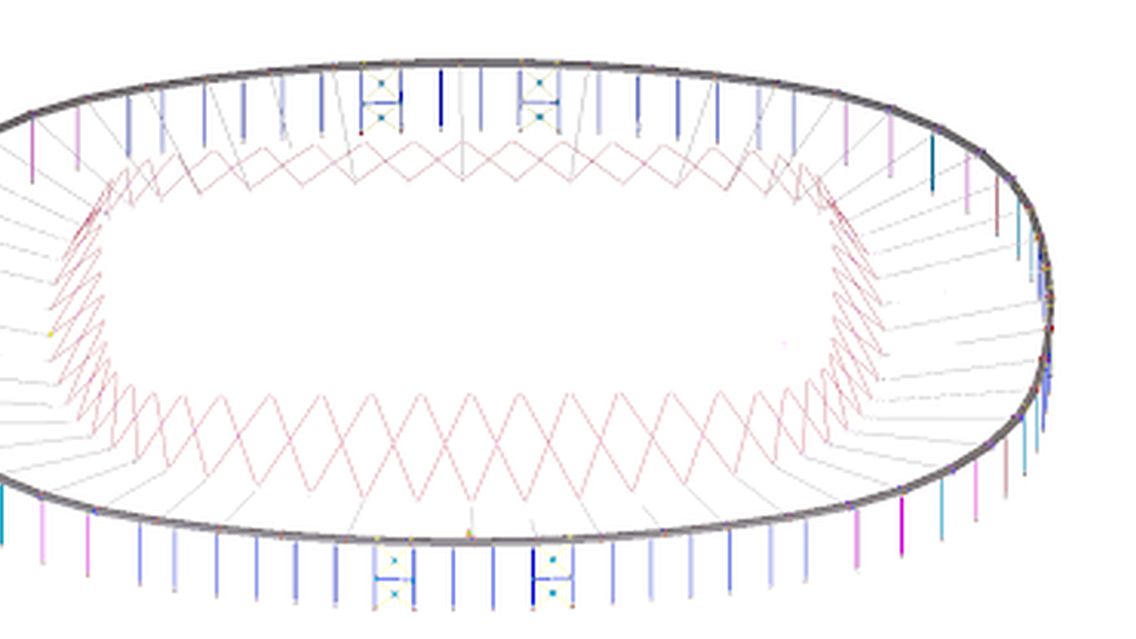

- Roof horizontal support three points coplanar, the same point four support connecting plates are not coplanar, drawing marking is difficult.

We are proud of

- 3D model detailing, grasping 3D coordinates of design drawings, automatic positioning and lofting of bars, model analysis

- Node detailing, classifying different nodes, node data management in Excel, and automatically modify nodes. Special nodes are customized to match the shape of the stadium.

- Customized 3D Automatic drawing of complex components to improve productivity.

The total steel consumption of the project is about 7000 tons, the cable is 750 tons, and the maximum single weight of the component is about 32 tons. The steel roof is a main and secondary beam structure of gravity prestressed spoke suspension cable. The long axis of the structure plane is 250 meters, the short axis is 200 meters, the cornice is 50 meters high, and the maximum cantilever span is about 61 meters. The cable net system is composed of an outer ring beam, inner ring cable and radial cable between inner and outer rings. The ring cable is saddle shaped, the plane is projected into a ring, and the V-shaped diagonal brace supports the roof on the cable clamp node. In this project, Wuhan Dunxin is responsible for the detailed design of all the main steel structures, except cable structures. The detailing is all completed using Tekla.