Construction of a multifunctional commercial property

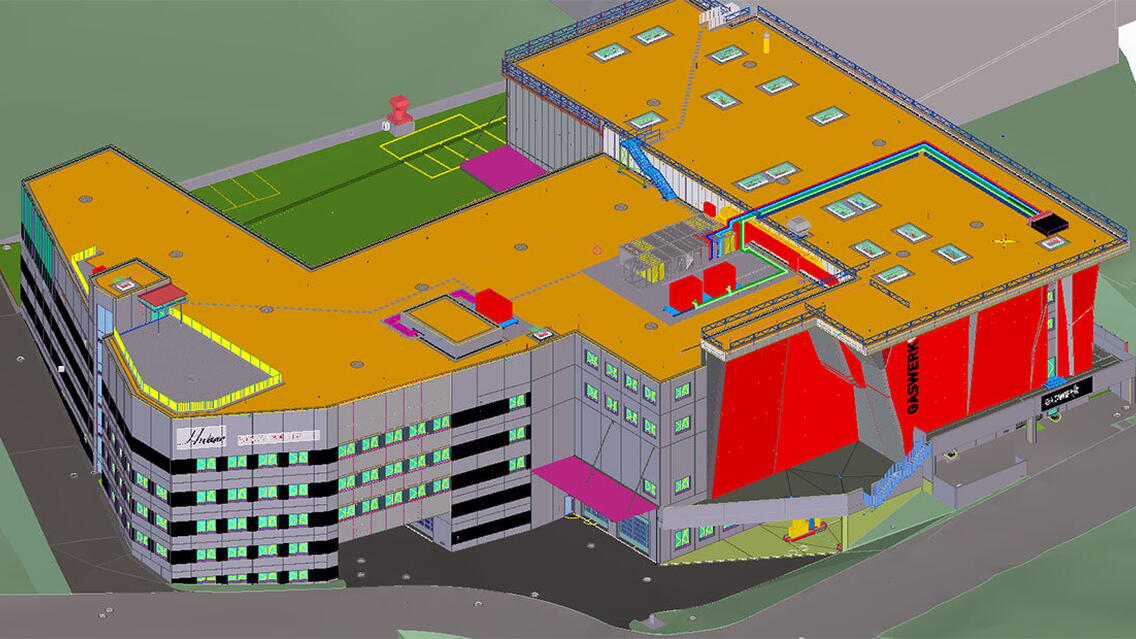

The project involves the construction of a multifunctional commercial property with a total of around 14,000 m² of usable floor space.

The three different tenants are the transport operator Sihltal Zürich Uetliberg Bahn SZU AG, a wholesale beverage supplier and the largest indoor climbing center in Europe, and they will move into the property in January 2021. The Swiss company Methabau AG operates as a full-service contractor and is responsible for project development, complete BIM and 3D planning. Detailed design and the actual construction process will be accomplished by its own construction teams and long-standing partner companies.

Challenges & success factors

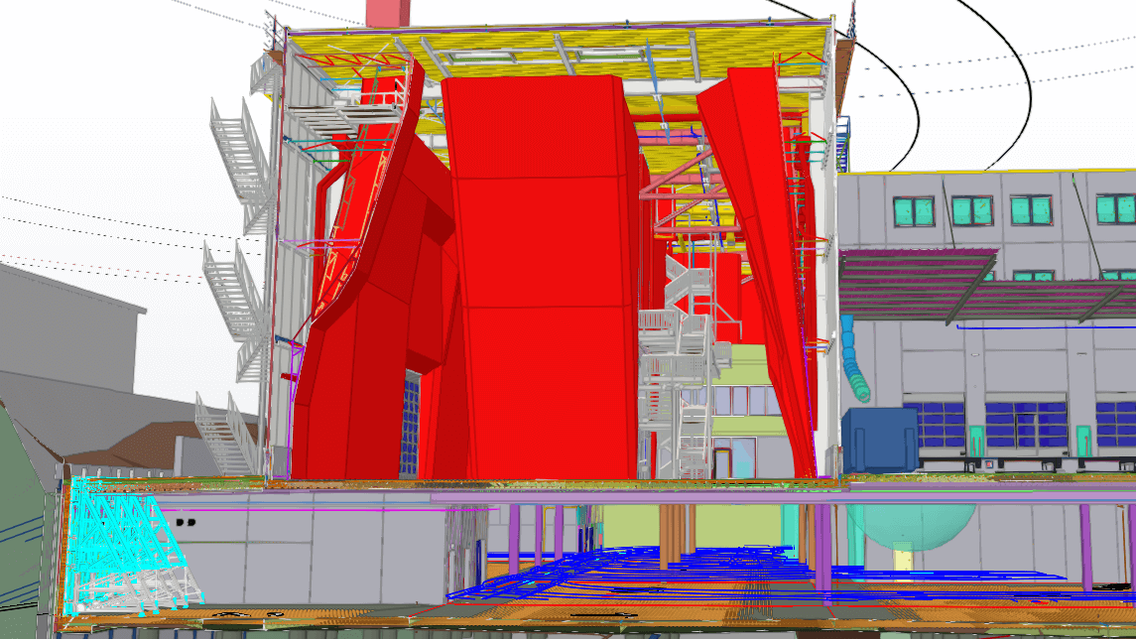

A specialized company from Italy constructed the climbing walls, including the substructure. The collaboration with this company was a new challenge – the standards for planning and data exchange had to be redeveloped and defined with each other. The entire planning of the climbing walls was coordinated in the Tekla model and realized by exchanging IFC data. At the construction site, all drill holes for fixing the substructure were added to the concrete in advance. All of these drillings (approx. 2,000) were marked with layout points and calibrated without a single paper plan.

Collaboration and BIM process

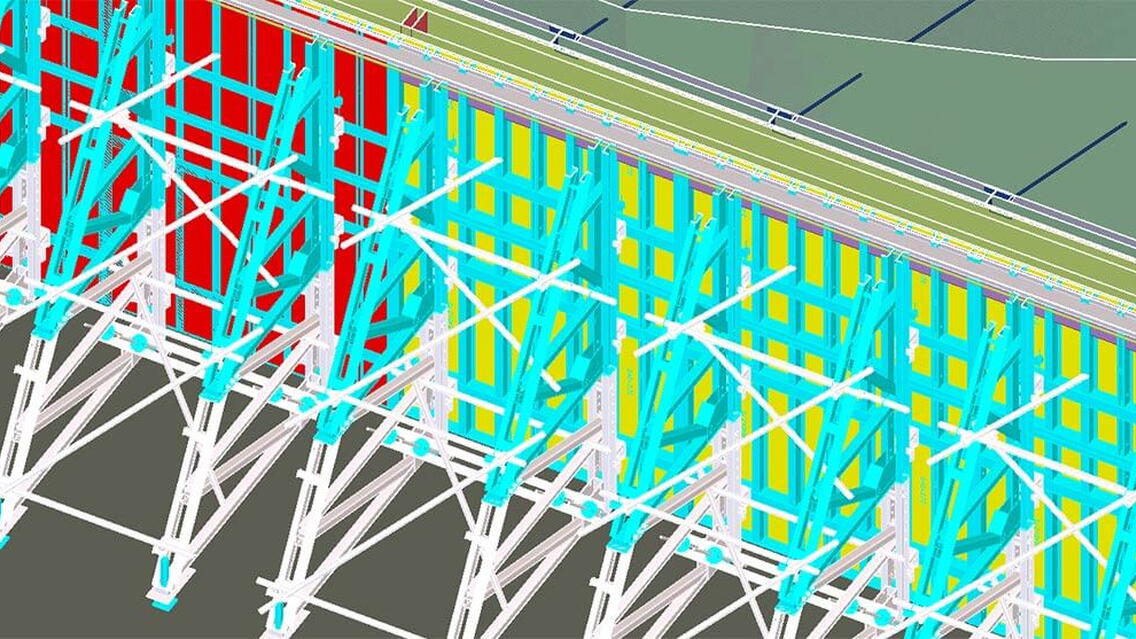

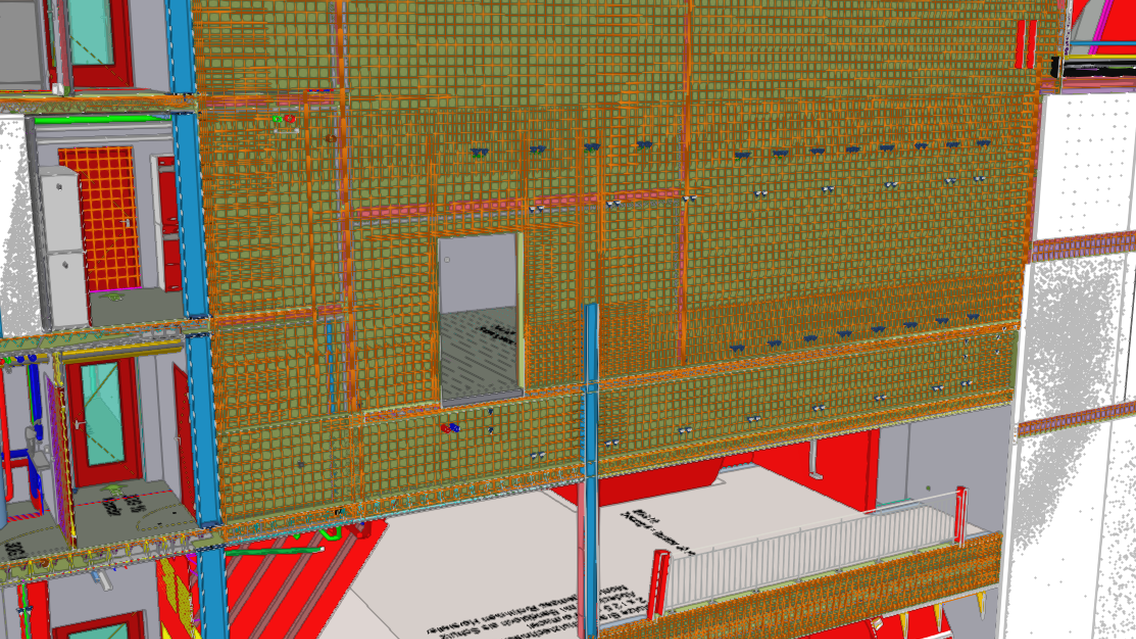

All trades were modelled with BIM, including the complete construction site equipment, construction cranes, scaffolding, large-area formwork and special civil engineering. Methabau works with a broad software portfolio, which includes Tekla Structures, Trimble Connect and Trimble Nova for MEP. The Tekla Structures Model was the central model for collaboration and communication.

The project team worked with two Tekla Structures models (one model for the entire structure and one model for the steel structure, as this was subcontracted) as well as IFC reference models for reinforcement, MEP and the interior construction. A total of 105 IFC or DWG files are stored in the BIM collaboration platform Trimble Connect. For example, DWG files were used to give the team a better overview regarding tractrix curves, pour units or the land register plan. The team also completed the entire in-situ concrete and rebar detailing in Tekla Structures. The ordering and production of precast elements was completely handled via IFC, without any paper plans. All layout points were measured and implemented with layout points via BIM to Field, requiring almost no paper plans.