The world’s longest bridge built without drawings

Randselva Bridge is a 634-meter-long cantilever concrete bridge being built without drawings. It’s based solely on BIM-models.

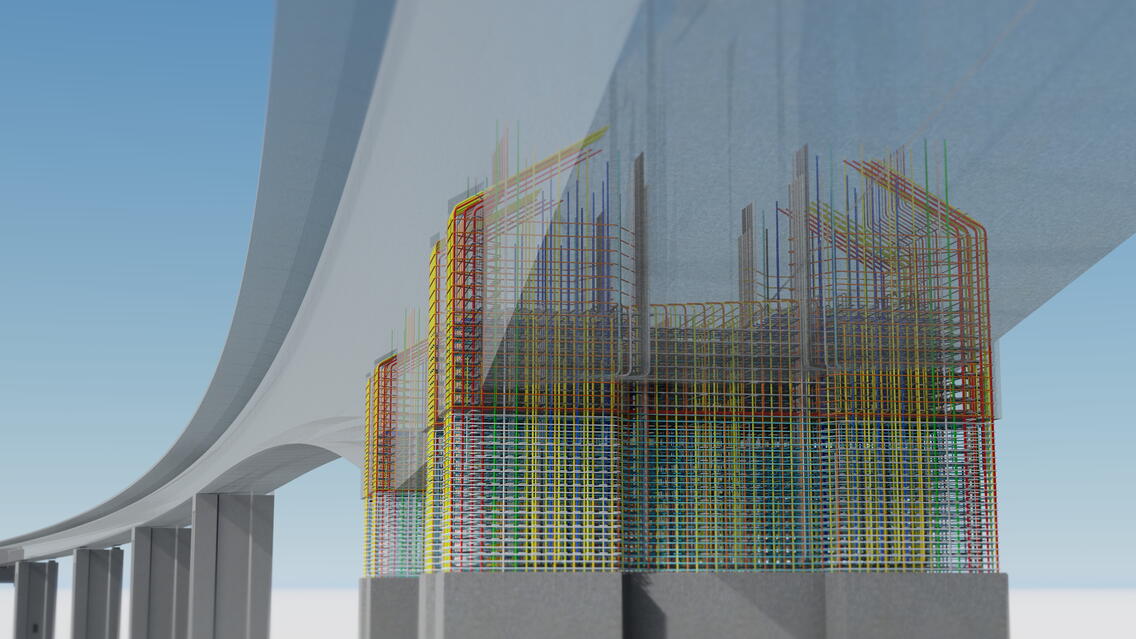

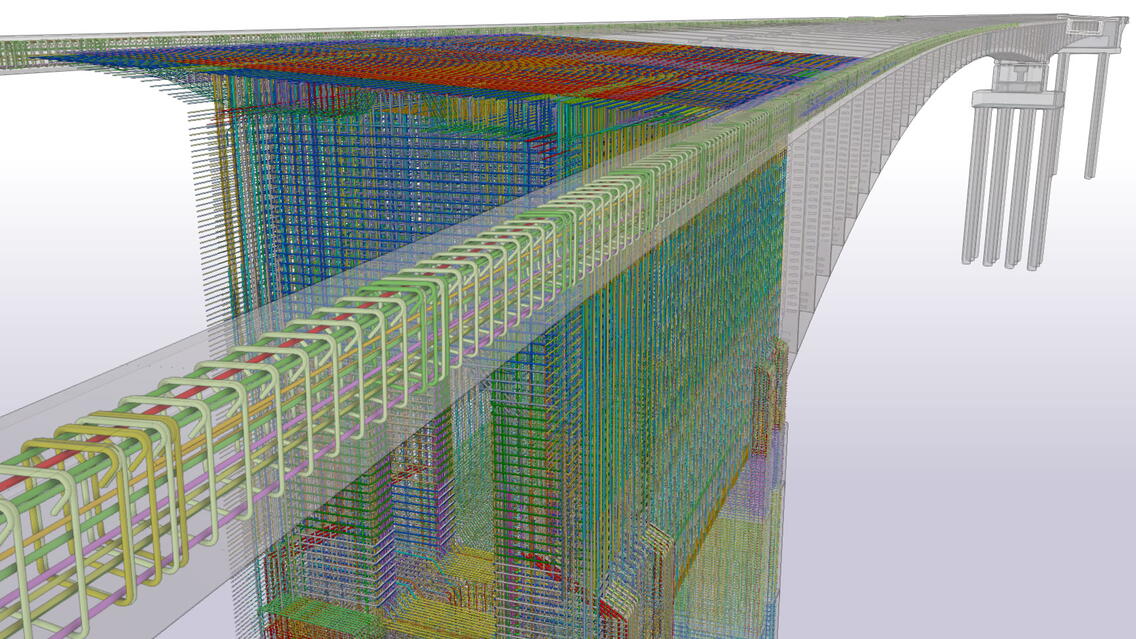

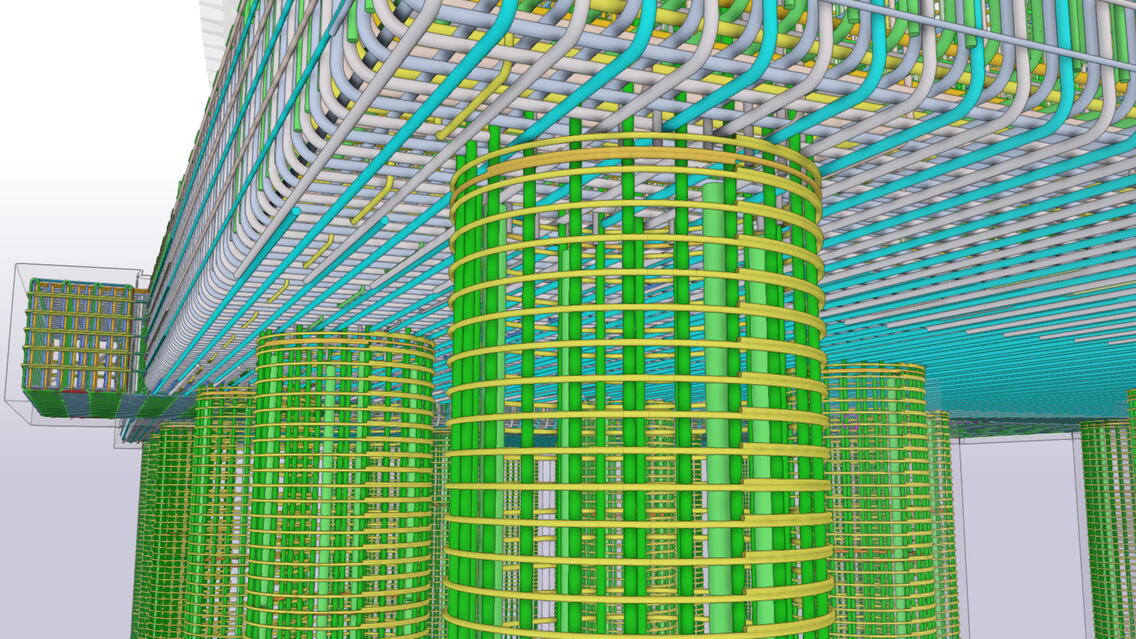

Randselva Bru is a 634-meter long concrete box girder bridge near the city of Hønefoss, around 50km north-west of the Norwegian capital. It has a main span of 200 meters and six piers that range in height between five and forty-two meters.

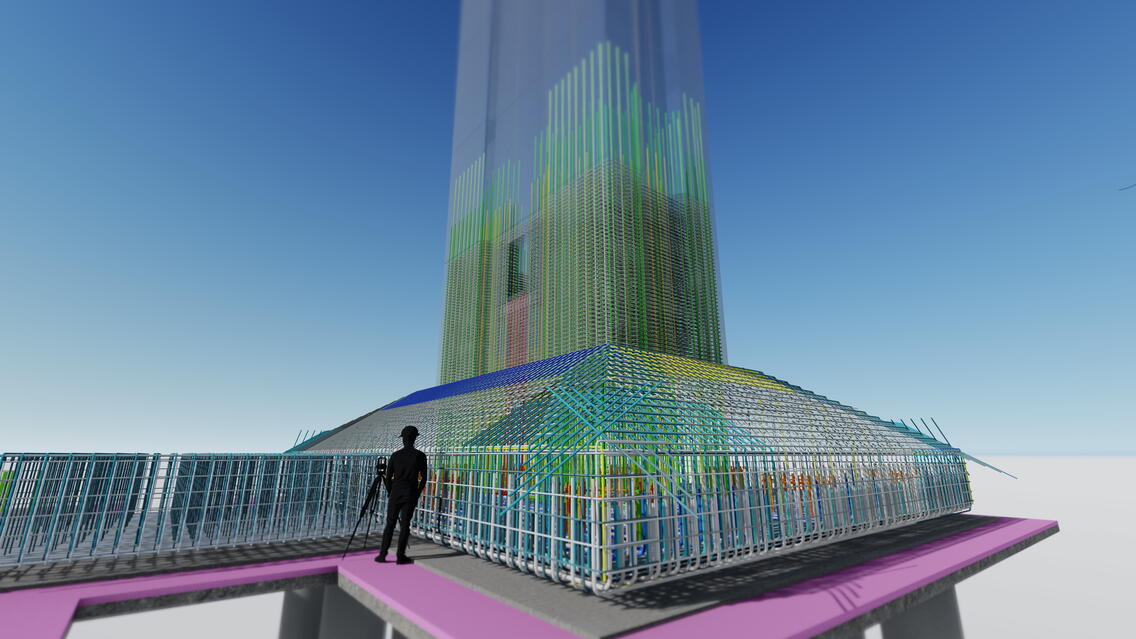

The various complex geometric forms of the structure are being constructed using the balanced cantilever method. At its highest point, the bridge deck will stand 55 meters above ground level. The largest hammerhead will be 21 meters long, 8 meters in width and 14 meters in height, which is about the same height as a four-story building.

Four interesting facts

- 95% of all information is transferred to the contractor with IFC files.

- Parametric design has been used to model ~70% of all objects.

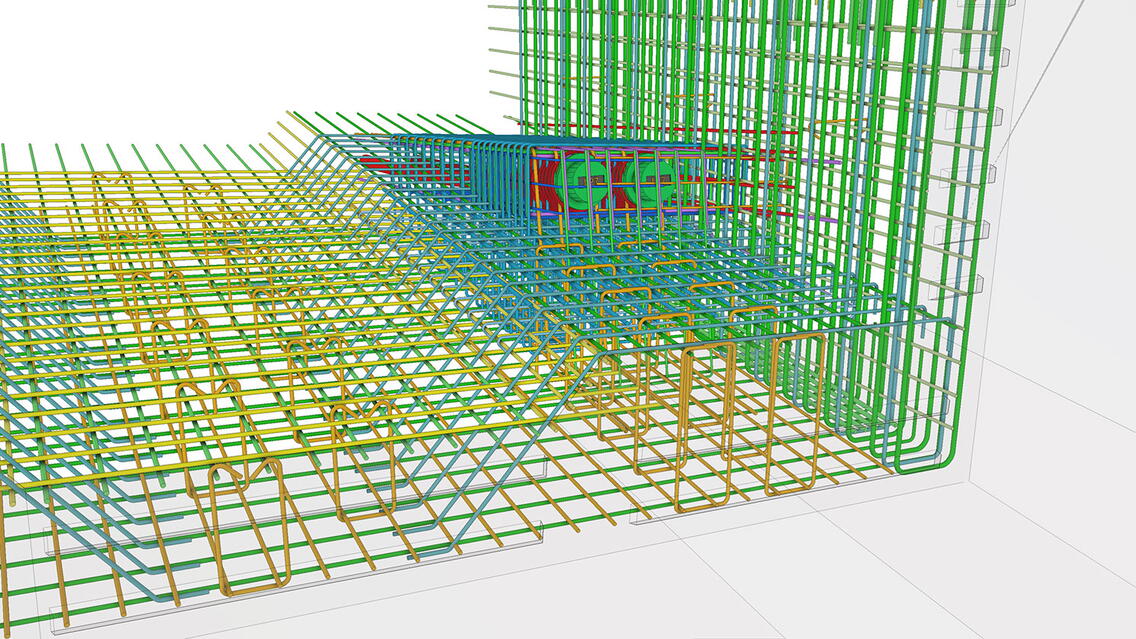

- The BIM-model contains over 200,000 rebars and 250 post-tensioning cables.

- The Design team is located in four cities across four countries (using Model Sharing).

Adapting new technologies

This project was selected as a local winner because it demonstrates the benefits of adopting new technologies and challenging the status quo. Together with their partners, Sweco have developed a BIM-model that carries all necessary information to build the bridge without the need for drawings, using Tekla, Trimble Connect and SiteVision. The customer has also used Tekla Model Sharing in successful cross-border collaboration.

The benefits of using BIM and Tekla software

Motivation:

The project owner, Statens vegvesen has seen a significant reduction in change orders when using BIM models as a basis for producing drawings. Eliminating drawings predictively means reducing the number even further.

Challenge 1:

The bridge has a very complex and slender geometry. Very heavy reinforcement combined with post tensioning cable anchoring makes certain areas very challenging to design.

Solution 1:

Modelling all objects combined with clash detection ensures that the design is buildable. The 3d-model also enhances the understanding of scope of work at site.

Challenge 2:

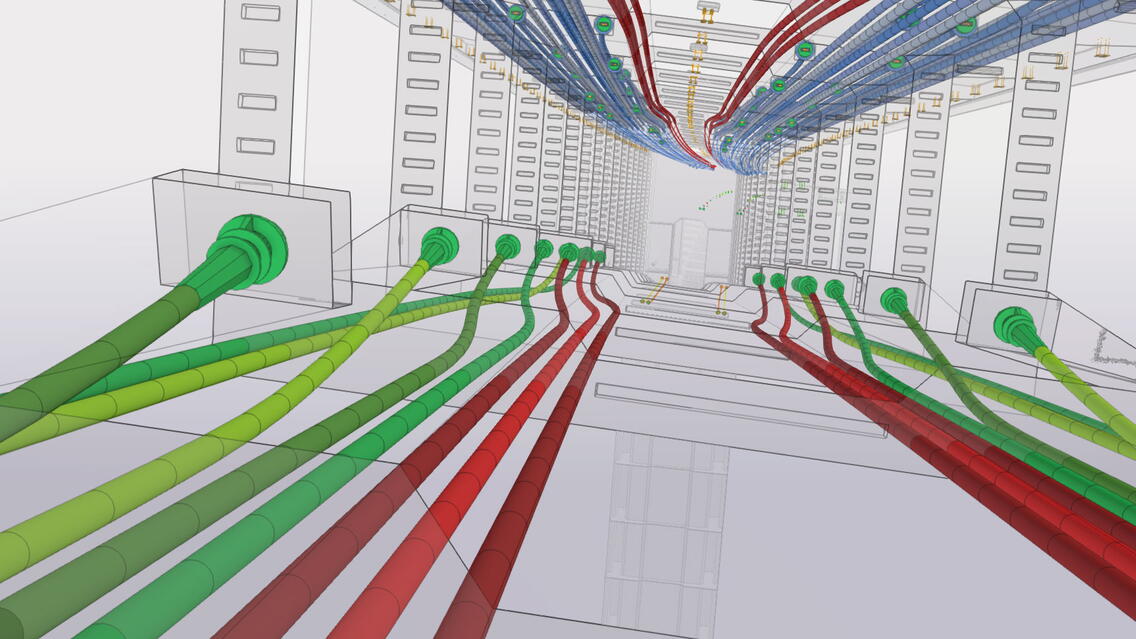

Randselva Bridge is the first structure that the contractor (PNC) builds without using drawings.

Solution 2:

Trimble Connect provides a platform for IFC-files exported from the Tekla-model. Issue tracking in Trimble Connect helps shortening the reaction time when questions and issues arise at site. Trimble Sitevision also helps PNC understand the scope of work when planning the upcoming building stages.

Challenge 3:

The bridge has over 200 pour phases. Producing individual bar bending lists for every pour phase manually would be time consuming and prone to errors.

Solution 3:

As all reinforcement is modelled and labeled with a pour phase, the contractor (PNC) can automatically extract bar bending lists from the IFC export files at any chosen time, saving time and eliminating errors.

Additional benefits on this project:

- Better 4d (time) and 5d (cost) planning and control

- Flexible parametric designs enable easy revision and speedy changes.

- Reusable design with parametric design modeling.

- Drawings are often country-specific, while BIM model information is more universal to make cross-border collaboration easier.

Participants that use the model

- Sweco modeling teams:

- Oslo, Norway – BIM model coordination and quality control

- Copenhagen, Denmark – Parametric design, reinforcement

- Tampere, Finland - Parametric design, form and post-tensioning

- Katowice, Poland – Tekla reinforcement

- Armando Rito (calculations) - IFC export files from Tekla

- Multiconsult (3rd party control) – IFC export files from Tekla

- Vegdirektoratet (Norwegian road authorities) – IFC export files from Tekla

- Statens vegvesen (project owner) – IFC export files from Tekla

- PNC (Contractor) – IFC export files from Tekla

Would you like to find out more about how Tekla software can help your bridge projects? Click here