Pipeline renewal during full operation

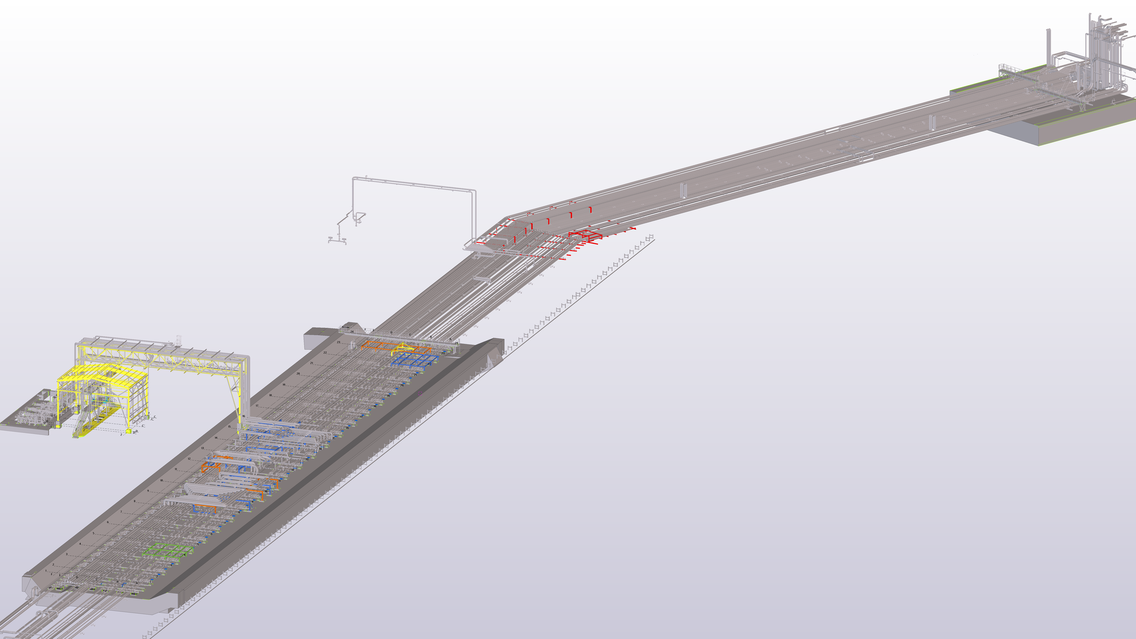

Global chemical company BASF had to renew and extend a pipeline route on its premises in Ludwigshafen, Germany. As the project would mean a production halt for a number of businesses, the project had to be completed in the minimum amount of time.

The German engineering company Voss und Kamb und Partner was tasked with the detailed design as well as structural design.

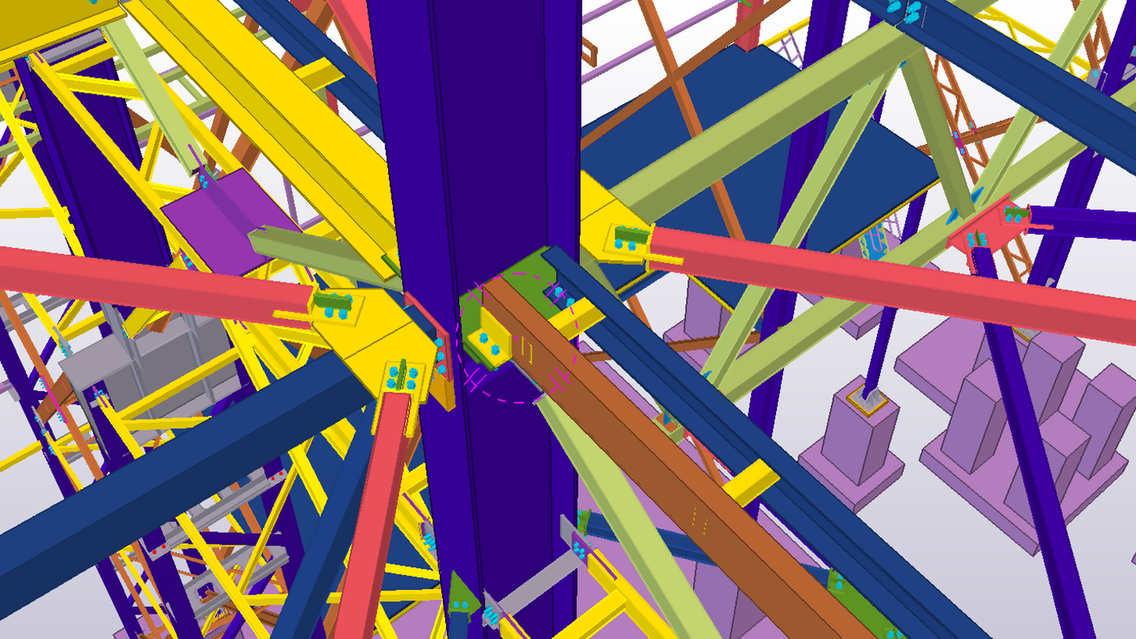

The company needed to quickly assess the situation onsite and find the best technical solution, which could be realized as quickly as possible. At the same time, the project had to be completed with the highest level of precision, in order to avoid clashes and other interferences on the construction site.

The reconstruction was done during operation of the plant. The engineers therefore had to plan for a partial deconstruction and the ability to compensate larger tolerances. During the project, a number of extensions and new structures were added. Thanks to the BIM model Voss und Kamb was already utilizing, the company was able to work on these as well “on the fly”.

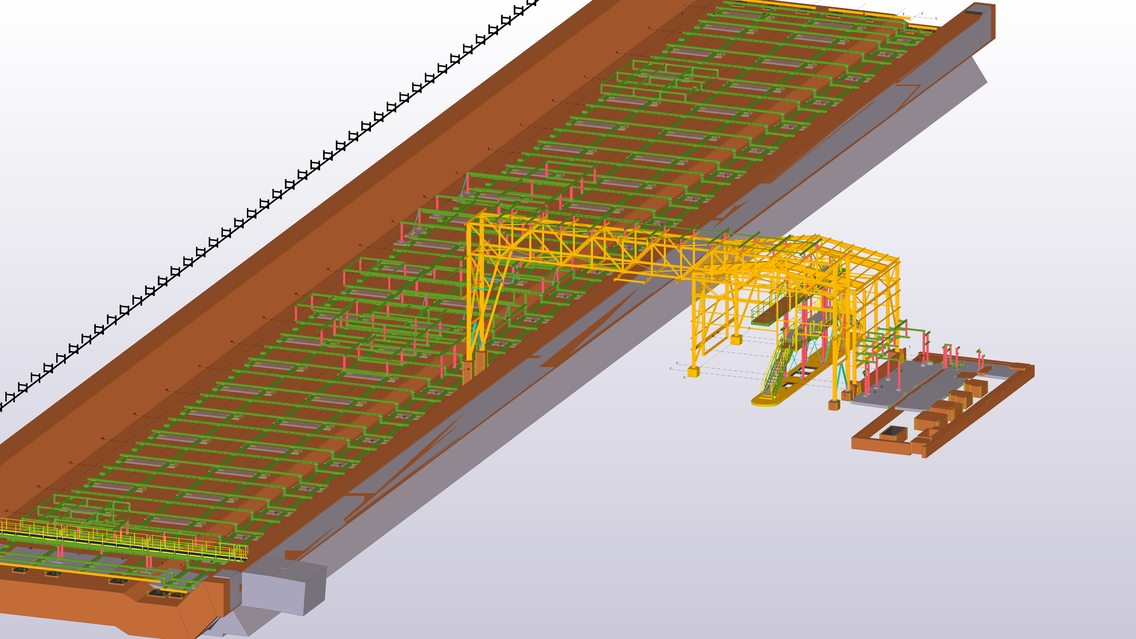

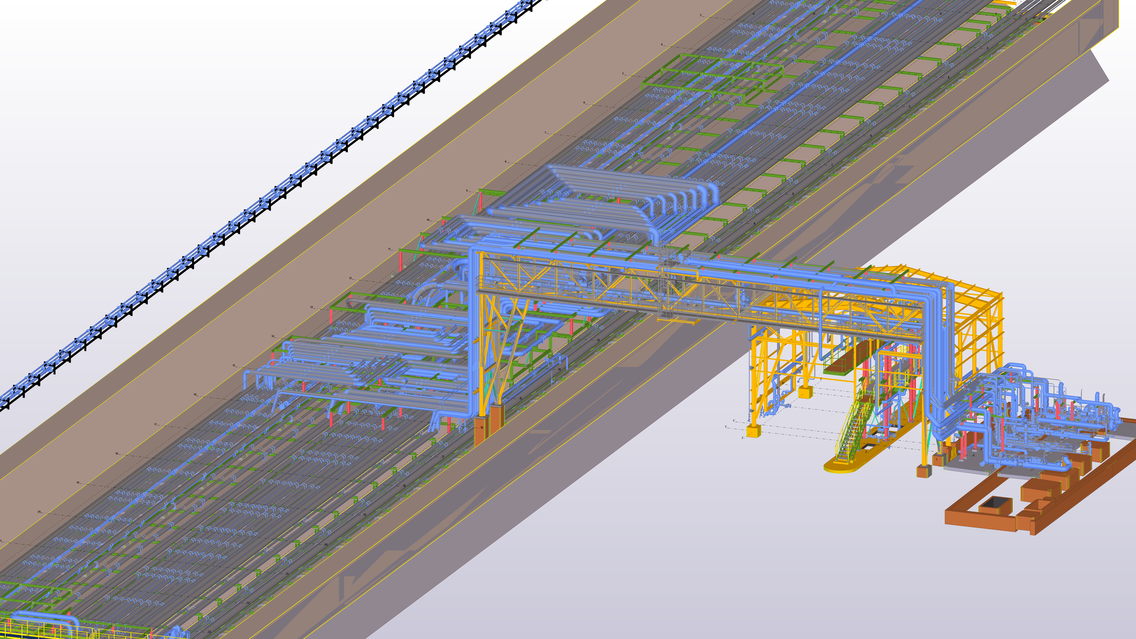

The BIM model was maintained from the very beginning of the project. Voss und Kamb started the project by capturing the existing structures with laser scanners. Based on this information, all other trades were coordinated. From the first scans to preliminary design, analysis and design and detailed design, the company put together an exact copy of the existing structures (as-built). The company was able to extract all relevant information - as detailed as required - from the constructible model.

Data exchange and project communication

All project parties, including owner, process engineers, piping engineers, steel detailers, concrete detailers, earthworks, fabricators and the erection team were able to exchange data in real time and benefit from the integrity of BIM. Apart from the extensive technical advantages, this made communication between the project parties significantly easier. The project language was BIM, which helped to avoid miscommunication. Nearly all possibilities and means of BIM were utilized and helped to complete the project faster than planned and without any reclamations. The customer’s and project partners satisfaction give proof to the validity of this technology and process.

Use of BIM and Tekla Software

- Entire project completed in 3D, all trades

- Deliverables from Tekla Structures:

- Production/shop drawings

- Erection/placing drawings

- Schedules, material reports

- Data files for production planning/management software

- IFC data

- Inclusion of all project parties and various software solutions and A&D programs

- Consistent and homogenous use of BIM from design to A&D, clash detection, visualization, problem solving and discussion as well as fabrication

- Resulted in fast project completion, reduction of costs and minimal downtime of production

- Challenging project with existing construction

- Partial refurbishment and extension

- Coordination with plant model (PDMS)

- Export to PDMS (Tekla Stuctures/PDMS interface)

- Comparison of models with point clouds

- IFC exchange with A&D solution

- DSTV exports/imports, e.g. Steel Office

- NC data export from the BIM model to fabrication

- 3D-DWG export to view in Navis

- Elements from suppliers in 3D

- Responsible for different trades and materials such as steel, foundation engineering, precast elements

Company

The German Engineering firm “Voss und Kamb” plans and executes engineering structures, plants, commercial and office buildings. Our focus lies on power plants, industrial plants and production facilities for the chemical industry. We stand for technical competence, creativity and decades of experience. In addition, we support our customers with consulting services. Over time, we have extended our offering from steel construction to complete building construction, such as office facilities, schools and administrative buildings. Our team consists of 35 qualified employees and we utilize a suite of software solutions to best fulfill our customers’ wishes.