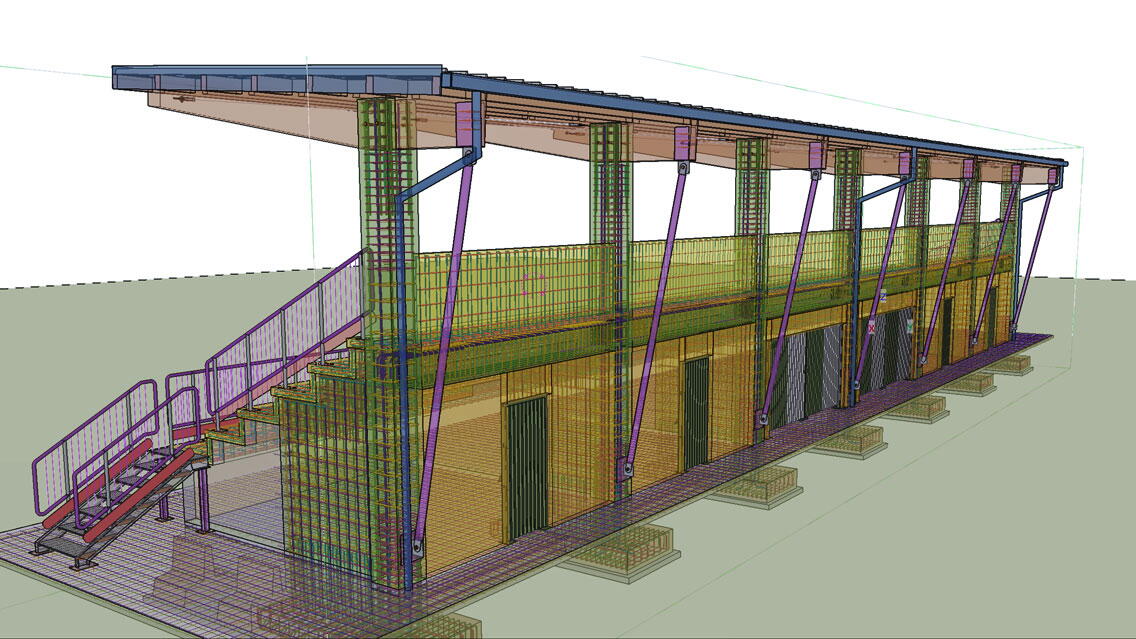

The project consists of the extension project with a new elevation and the construction of the grandstand adjacent to the San Martino Municipal Sports Field of the Municipality of Alseno (PC).

The project involves the preliminary removal of the seats prefabricated in c.a., the maintenance of the existing septa, the realization of no 7 plinths of foundation in adherence to existing foundations, and the construction of new reinforced concrete partitions connected to existing ones.

The supporting structure consists of septa from a frame made with pillars in c.a. size 50x50 cm and rectangular beams measuring 50x50 cm. The new steps will be made of reinforced concrete with an L-shaped section. The laying of steps was planned in c.a. to allow handling. Two metal stairs and a single ramp enable access to the structure. The new roof will be made of laminated wood, main cantilevered beams, and rear steel tie-rods.

The beams are provided for connections to the purlins, also made of laminated wood. There's also sandwiched anchored roofing panels consisting of a double prepainted sheet with interposed insulation for a thickness of about 6cm and total coverage of about 200 square meters.

There will be six bracing spans with ""Croci di Sant'Andrea"Sant'Andrea" in which the tie rods will be made with round bars of galvanized steel measuring 16 mm in diameter.

Advantages of using BIM

The Tekla Structures software has been used from the feasibility study/preliminary design phase up to the executive design of the structure. Modeling involved the existing part of the structure and that in the project. This has enabled careful control of any interference between the two structures.

The BIM model developed with Tekla Structures has been shared, since the preliminary stages, with the client using images extrapolated with Trimble Connect Visualizer. This has allowed an immediate and effective simulation of the work in the design phases.

The structural project underwent several revisions and variations following requests for changes/additions by the client that was quickly and efficiently received according to schedule.

Tekla Structures has made it possible to obtain the graphics with extreme precision with a very accurate level of construction detail. The software allowed the extrapolation of the reports of the quantities of the materials, which were constantly updated and helped speed up the operations of metric computation.