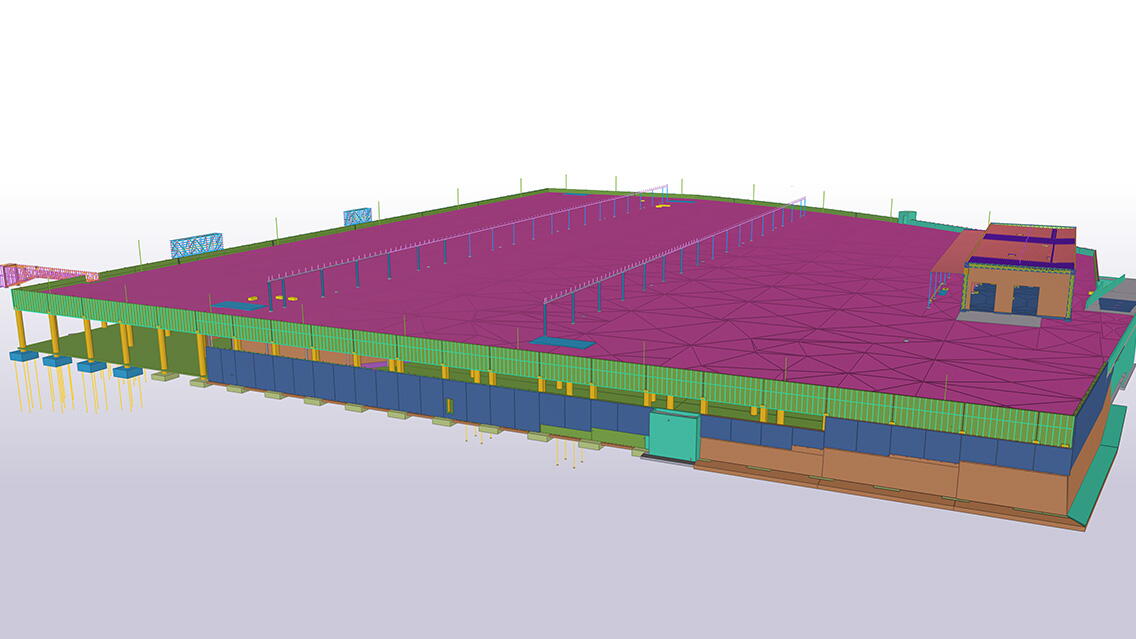

The new tram and bus depot being built in Ruskeasuo, Finland, will become one of the main depots for tram and bus services in Helsinki. It will be used to store 100 trams between 28 and 35 meters long. The bus depot on the roof of the building will have a capacity of 220 vehicles. The depot is a response to the city's objectives of expanding tram services and will be used to service, for example, the future express tramways of west Helsinki. Charging stations for electric buses will be provided at all bus stations.

Construction of the €170 million project, which includes 13 km of track and 30 geothermal wells, started in the winter of 2021 and will continue until early 2024. 12 000 m3 of low-carbon concrete will be used for the project, and ten bat houses will be built nearby. Traffic at the depot will start in August 2024. Skanska Infra Oy is the contractor for the project.

Visual 4D scheduling clarified the phasing

The 4D schedule at the start of the project provided a clear visual representation of the phasing. The project got off to a smooth and efficient start with a model -based schedule, and the modeling continued throughout all phases. The building information model was a key tool for coordination and ensured the quality of the plans. The BIM coordinator appointed for the project guided the coordination of the models in the building information model meetings. Up-to-date model reports were maintained in the project bank, for example in BCF format. The BIM coordinator also used virtual reality for coordination using Sweco's VirtualSite platform.

The Cave space used in the project was utilized in various ways. It has been used for user experience reviews, planning meetings and stakeholder meetings. The Cave has been particularly useful for reviewing details of the depot's operations, such as the location of the workshop's utility points and details relating to work safety during operation, which has allowed the needs to be taken into account in the design.

The information modeling was used for GEO planning, estimating, machine control and space allocation

GEO planning made particularly extensive use of information modeling. For example, drainage, trenches, and leveling were modeled and coordinated with other design disciplines. The GEO model also described the support of the project periphery and the rock surface model after excavation.

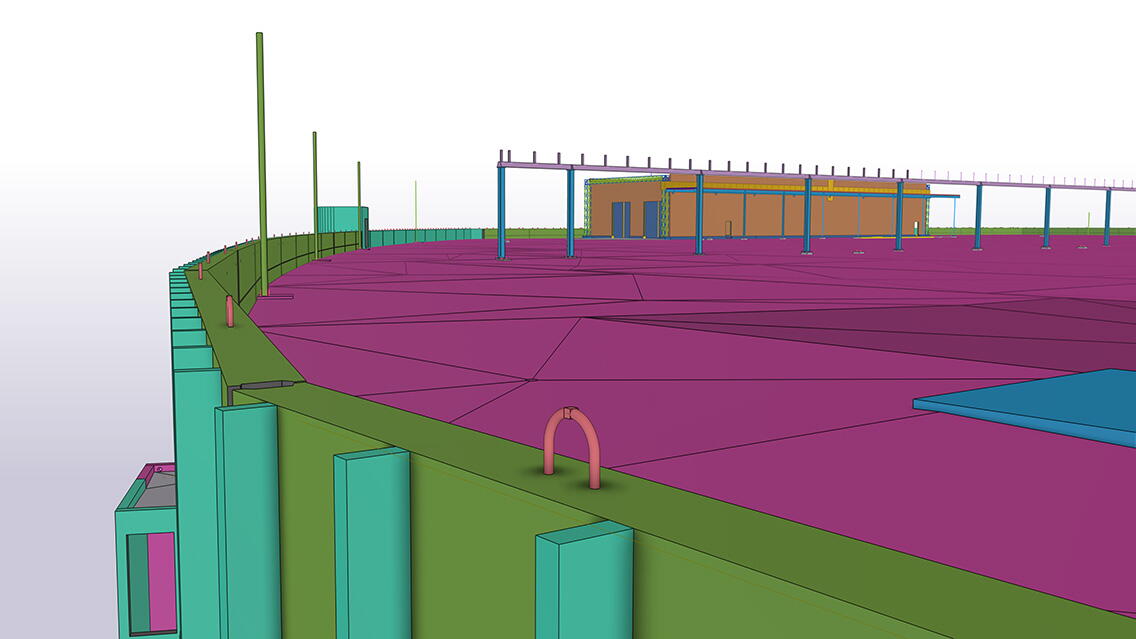

The models were also used for estimating and machine control. The photogrammetry data produced by the drone provided measurable information on the site. Photogrammetry has been used for detailed measurement and modeling of the sub-structures.

The project involved 360 cameras and the OpenSpace Capture application. Weekly mapping has enabled the project team, working all over Finland, to have an up-to-date view of the situation throughout the construction phase. The combined view of 360 images and the building information model provides an excellent illustration of the site and design situation.

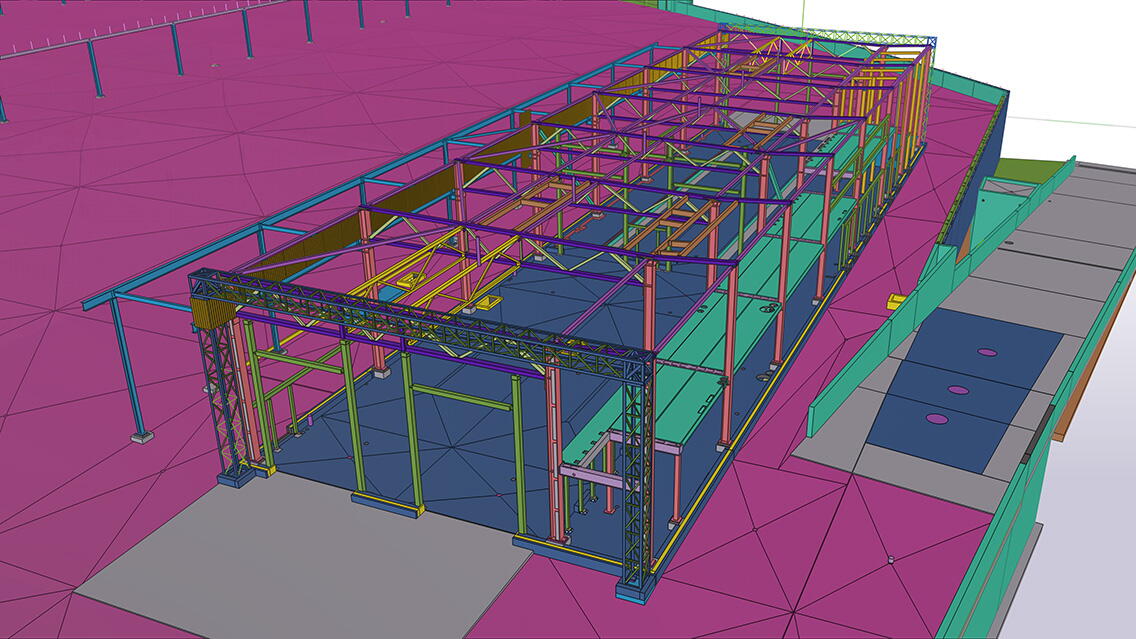

For the operation of the depot, it has been particularly important to understand the space required by the different types of trams and to coordinate it with the technology, the maintenance levels in the workshop, and other fixed structures. The structure gauge of the trams and the tolerances, for example, swaying, were described in separate models. Similar layout models were also made for the track electricity danger zones and pantograph trajectory, as well as for the overhead line trajectories and the track section. Almost all of the layout models were generated using the Grasshopper-Tekla live link using a parametric design. The architect also modeled the exit routes to ensure that the routes met regulatory requirements. All generated layout models were used for collision analysis and other coordination.

Building information model was an important tool for sourcing product parts and proactive work planning

The model has been used for quality assurance of product parts, and all prefabricated structures and related products have been modeled according to national standards. The cloud-based Trimble Connect platform has ensured up-to-date design data for all project parties. Examples include the use of different views made from the model by the site management team and the flexible production of quantity and cost calculations. The information model has also supported proactive work planning in the area of work safety.

The project involved using the SmartDrawings ™ platform developed by Sweco, which allows the models to be opened on all devices via a link or QR code on the drawing. The platform made it easy to view the model of the frame during the construction phase.

Significant amount of sustainable development solutions

The project is applying for a BREEAM Excellent environmental certification. In addition to the traditional carbon footprint calculation, the CO2 calculator for structures developed by Sweco has been used, which utilizes carbon footprint data from the Finnish Environment Institute's CO2data.fi service. The CO2 calculator works directly in the Tekla Structures software, allowing flexible calculations for different parts of the building and, for example, for material choices that make use of the circular economy. The calculator also enables the use of parametric design as part of the CO2 comparison.

The project’s target is to use 90% of waste materials. Low-carbon concrete is used in construction. At the end of the project, the information modeling material will be handed over to the client in accordance with national standards to support the operation and maintenance tasks.

The Ruskeasuo tram depot is a model example of an innovative project where the benefits of new technologies are tested agilely, with the best experiments applied to everyday operations. The whole project team has demonstrated a particular ability for information model-based collaboration. The building information model has been one of the main tools of the project.

The roles of the project partners:

Main contractor: Skanska Infra Oy

Structural, HVAC and electrical, sprinkler design and fire safety engineer, BIM coordination: Sweco Finland Oy

Architectural design: APRT Architects Oy

Surveying work: EXACT AIP-Mittaus Oy

Geotechnical design: Sipti Infra Oy