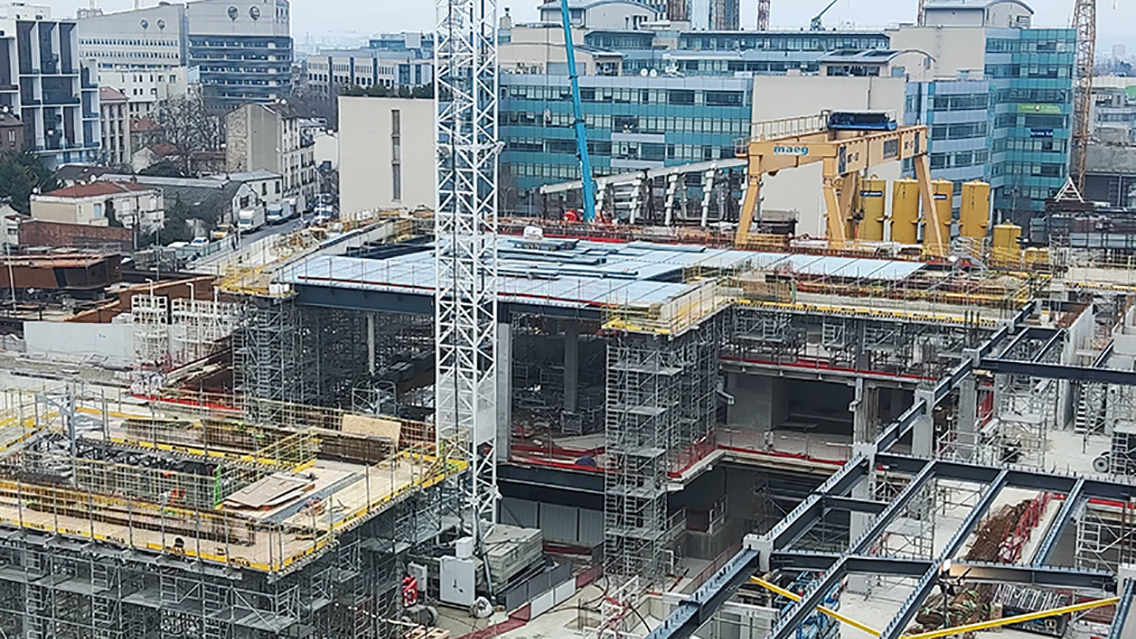

Located to the west of the Saint-Denis rail line, at the intersection of Rue Pleyel and Rue Francisque-Poulbot, Saint-Denis Pleyel station plays a key role in the Grand Paris Express project. It is the transfer point for lines 14, 15, 16, and 17 and also provides a connection to RER line D via the Pleyel urban crossing. In addition, line 13 of the metro can be accessed from the public space around 250 meters from the station.

With a daily passenger flow of 250,000, this station is considered the nerve center of the Grand Paris Express. It was designed by Japanese architect Kengo Kuma, and Egis rail and Tractebel are in charge of infrastructure management. CMBC METAL is also working on the project on behalf of Eiffage Génie Civil.

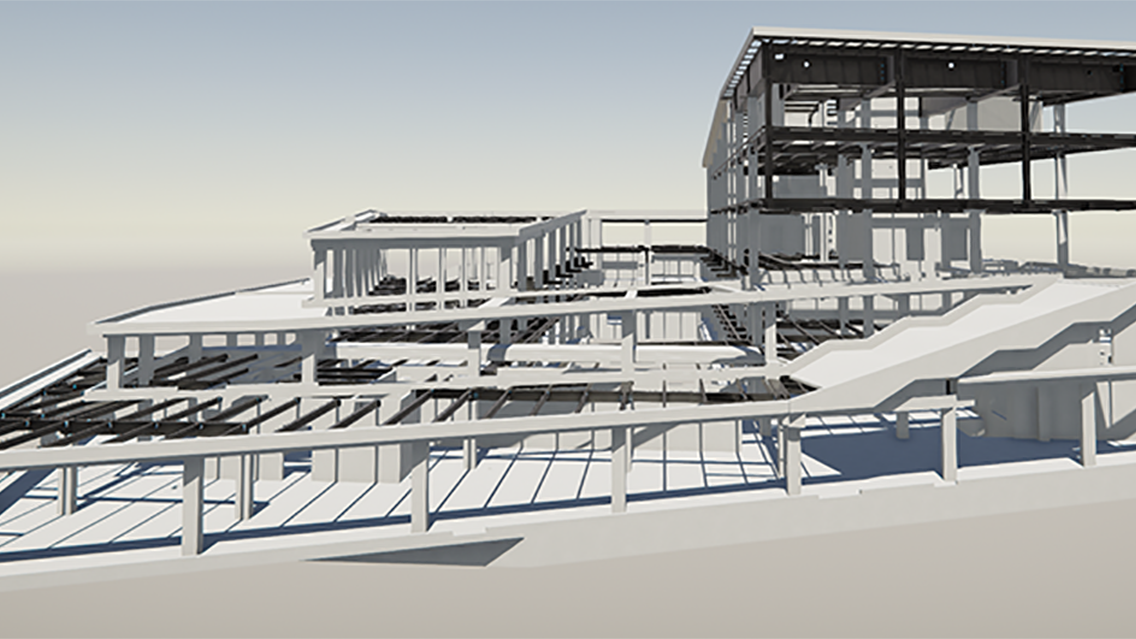

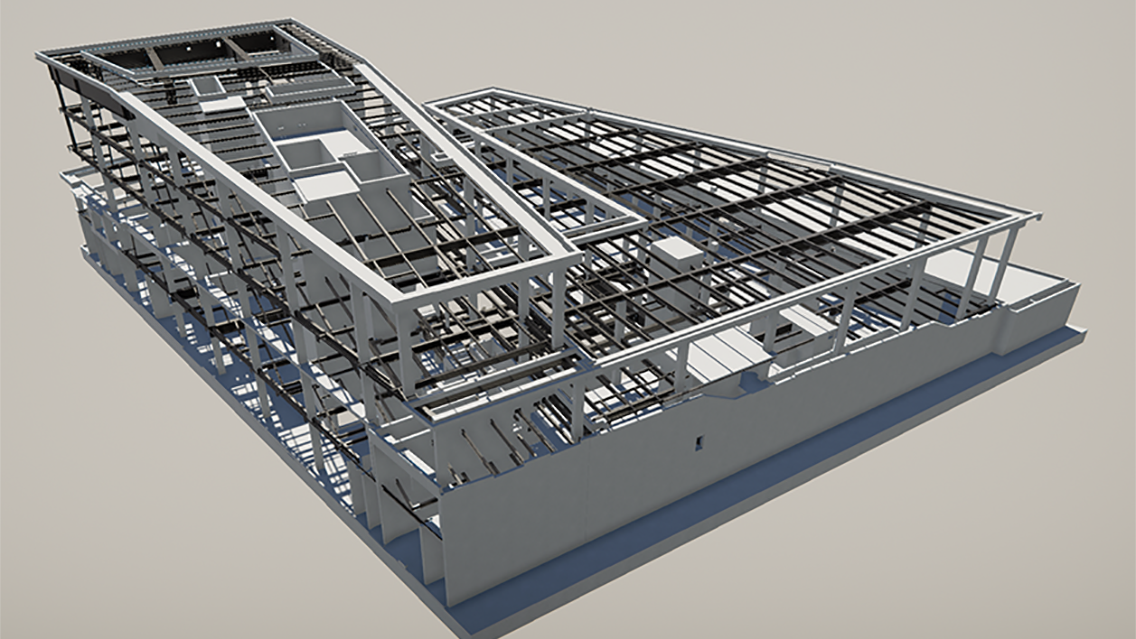

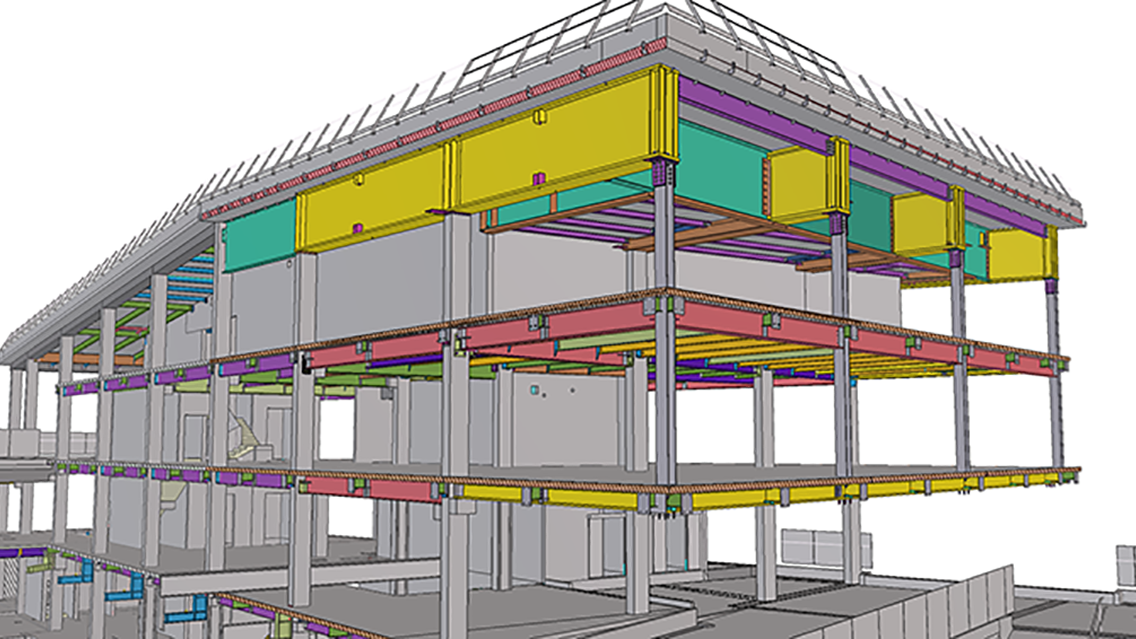

The construction project used a single calculation model for the steel structure and concrete, focusing on a network of beams connected by dowels to the slabs and supported by corbels or passing through concrete verticals. The system features numerous singular points and complex nodes, which were modeled in Tekla and calculated using Idea Statica. Pre-seals and anchors were installed in correlation with the reinforcing bars, and sleeves were incorporated to allow concrete columns to start on the steel beams.

The steel structure was perfectly modeled in Tekla, with ductwork, suspended ceilings, skylights, and escalators seamlessly integrated into the concrete model. In addition, Trimble Connect AR was used to control the 2m-high PRS.

The superstructure project extends over four levels, with a total surface area of 11,000m² of collaborative tubs resting on a 760-ton steel structure. Three of the levels feature 10-metre cantilevers suspended from 2-metre-high, 22-metre-long PRSs, each weighing 40 tonnes.

We used several digital machines for different tasks, including Ficep's 1001 DFB for cutting and drilling, Ficep's Tipo for plasma cutting, Voortman's V505 for angle cutting, as well as the BIM Master and Layout Master for the AGT Robotics welding robot.

We used Trimble Connect to visualize the Tekla model, both in the workshop and on-site. This solution gives us the advantage of always having an accurate model with very detailed information. To collaborate with other trades, we export an IFC file to another BIM software package.