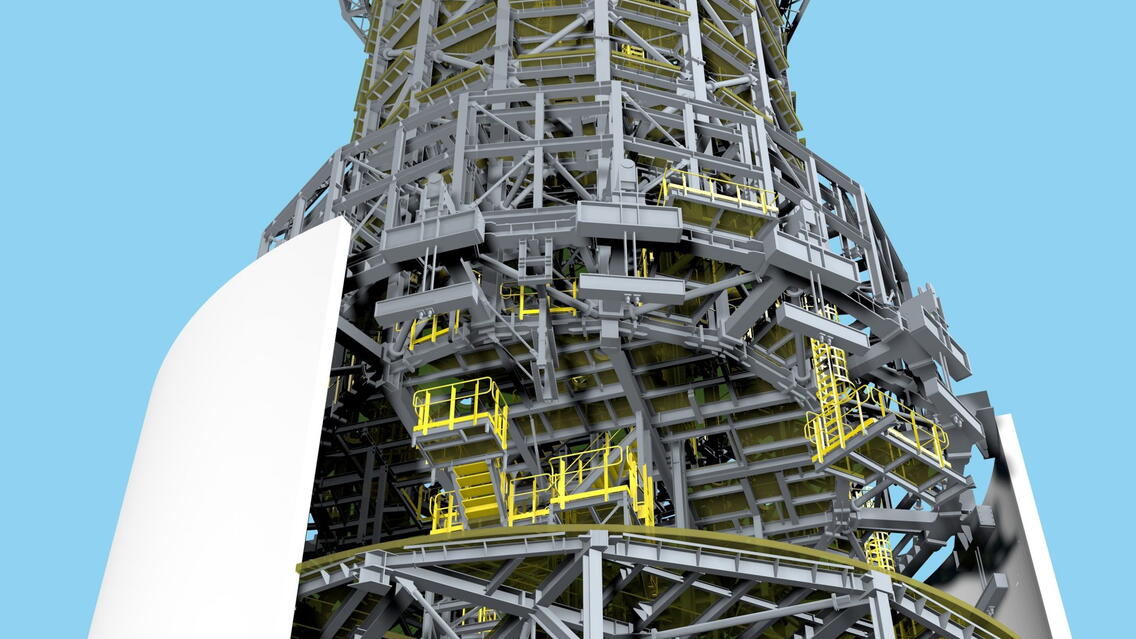

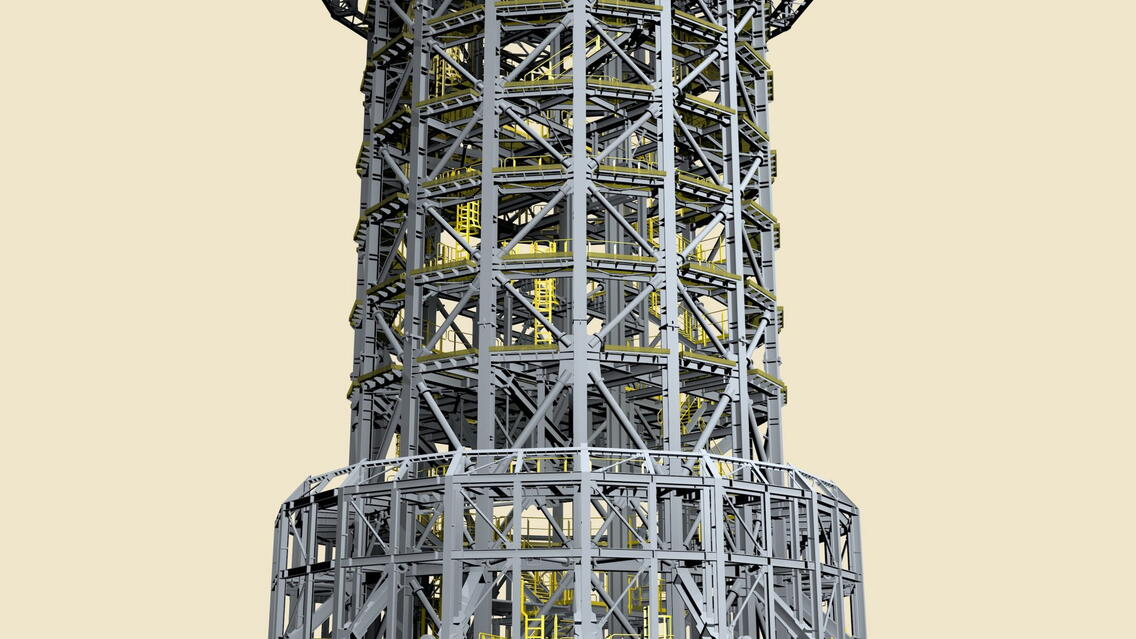

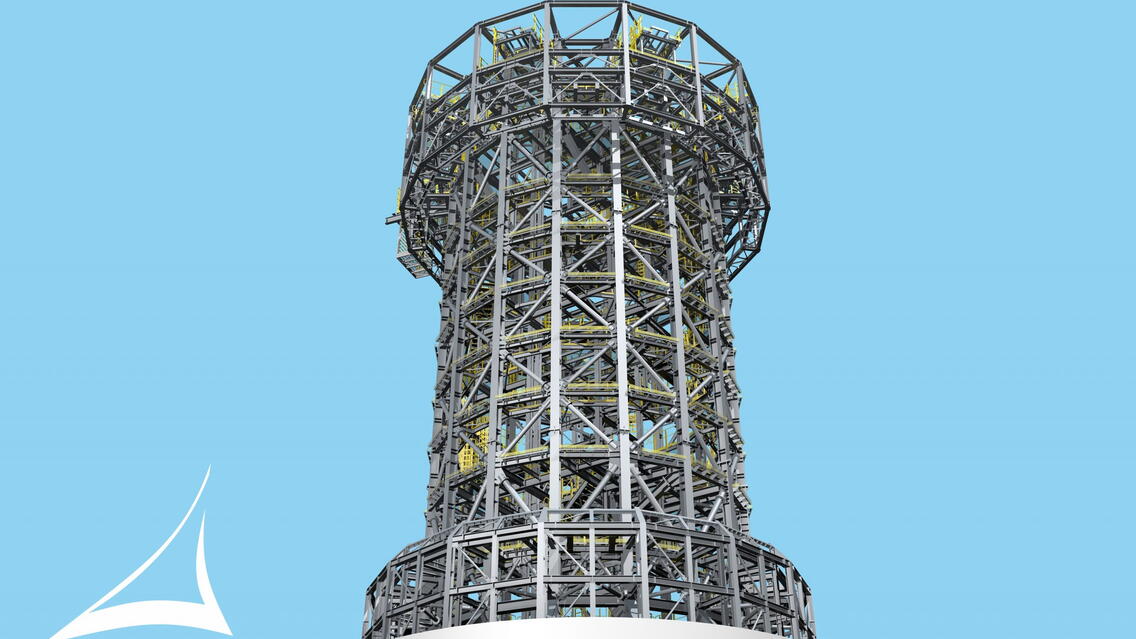

36-meter-high solar receiver (MSR), with a total weight of around 900 tons

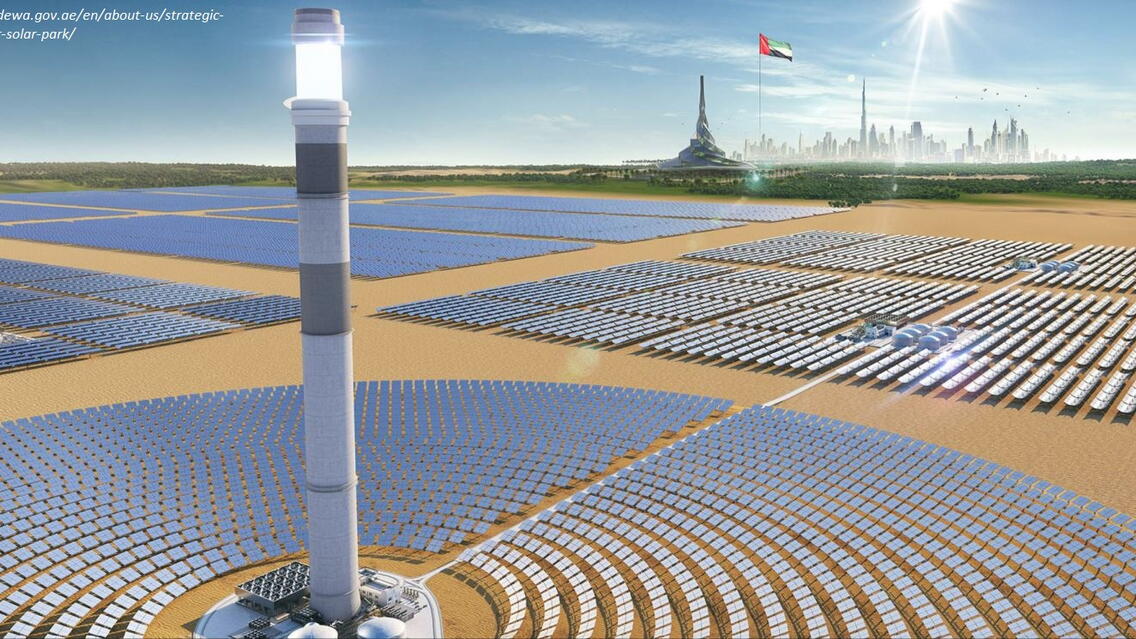

Mohammed bin Rashid Al Maktoum Solar Park is a solar park spread over an area of 77 km2 in Seih Al-Dahal, about 50 kilometers south of the city of Dubai. The plant was implemented by the Dubai Electricity and Water Authority (DEWA).

It has a planned production capacity of 5,000 MW by 2030, with investments totaling AED 50 billion. When completed, it will save over 6.5 million tonnes of carbon emissions annually.

The Mohammed bin Rashid Al Maktoum Solar Park is one of the world’s largest renewable projects, based on an independent power producer (IPP) model. Besides the three phases that consist of solar farms using PV technology, the long-term project also includes concentrating solar power (CSP)

Fourth Phase:

The fourth phase of the solar park is the largest single-site solar IPP project in the world that combines CSP and photovoltaic technology. The phase will use three technologies to produce 950 megawatts (MW) of clean energy. It will use 700MW of CSP; 600MW from a parabolic basin complex and 100MW from a solar tower; and 250MW from photovoltaic solar panels. The project will use 70,000 heliostats, and the largest global thermal storage capacity of 15 hours, allowing for energy availability round the clock.

8 of the world records for CSP industry made by Noor Energy 1

• world’s largest single-site investment project in CSP based on IPP model – USD 4.4 billion (AED 15.78 billion)

• world’s largest capacity of single CSP+PV project – 950MW

• world’s largest area of single CSP+PV project – 44 square kilometers

• world’s biggest quantity of molten salt used in single CSP project – 550,000 tons

• world’s tallest CSP tower – 260m

• world-leading tower with wireless heliostat technology – 70,000 heliostats

• world’s largest trough in a commercial CSP project – 8.2m

• most competitive LCOE – USD 7.3 cents /kWh, which can compete with fossil fuel electricity in UAE.

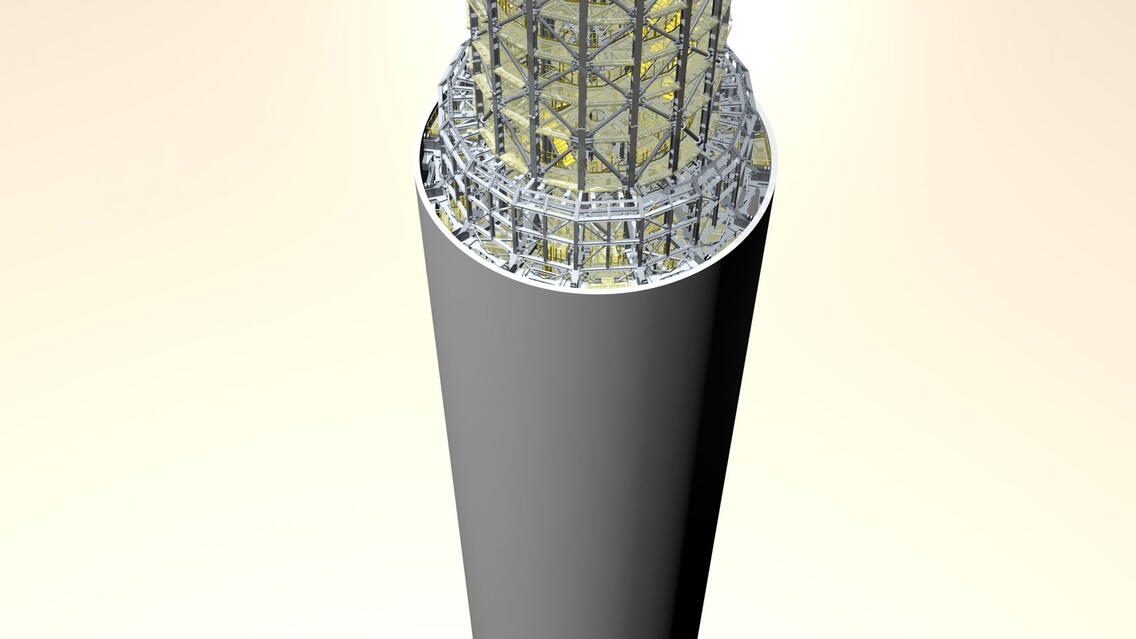

Project

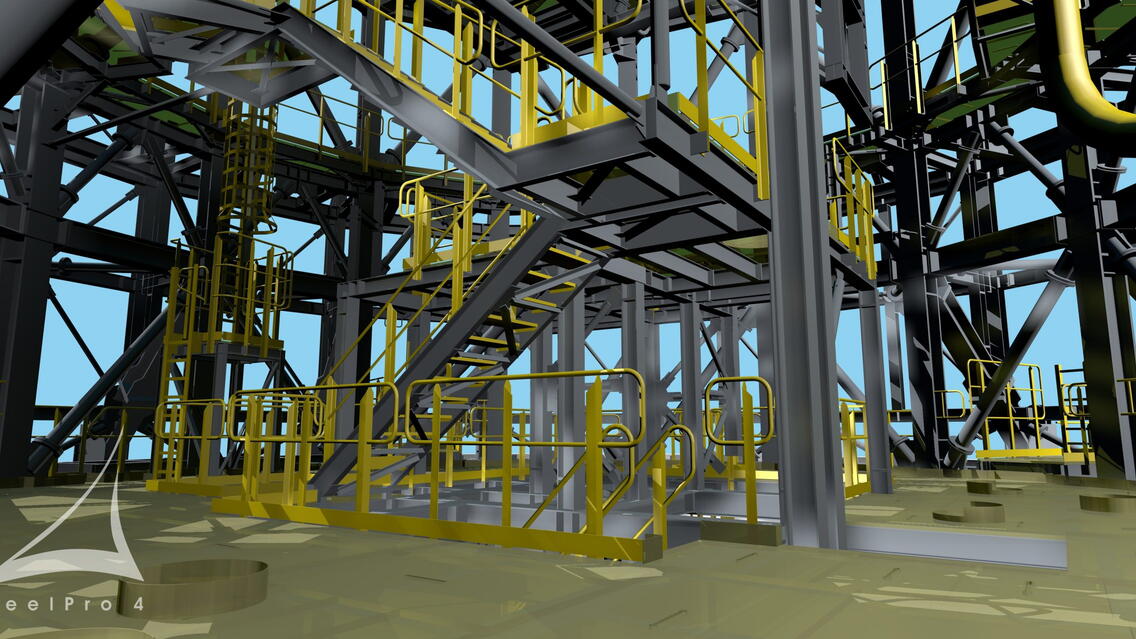

Company SteelPro 4 s.r.o. was awarded to make a Basic Design 3D model, general arrangement drawings, and to model all connections for steel structures of a 36-meter-high solar receiver (MSR), with a total weight of around 900 tons. The main steel structure is made of 16 columns, which are supported by three main platforms. The main steel structure is completed using secondary structures of platforms, various walkways, and supports for the equipment.

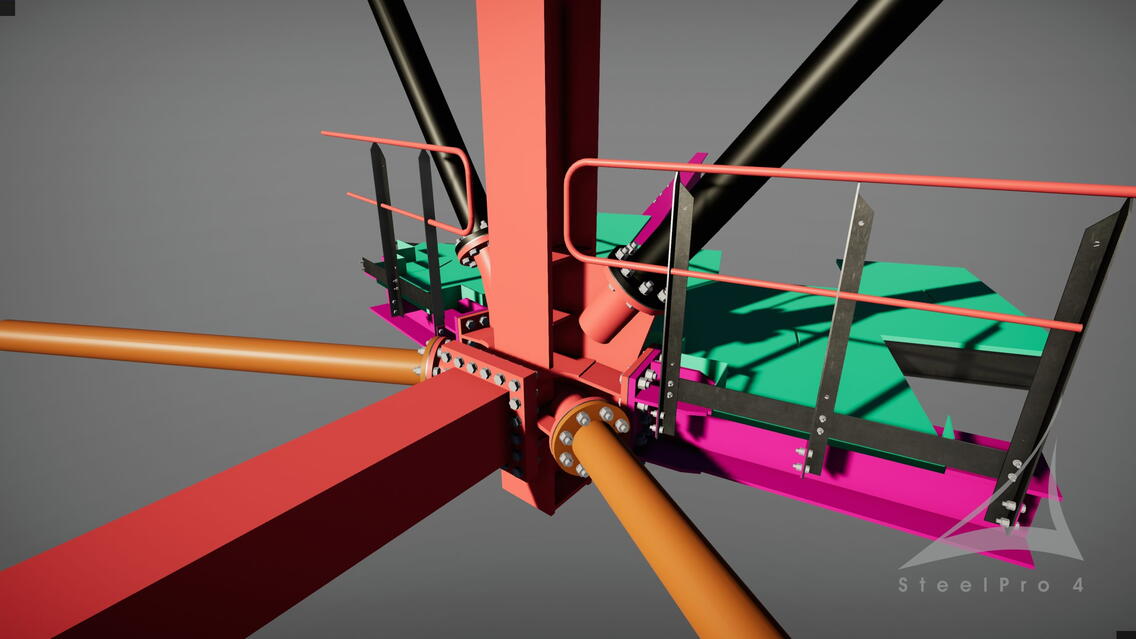

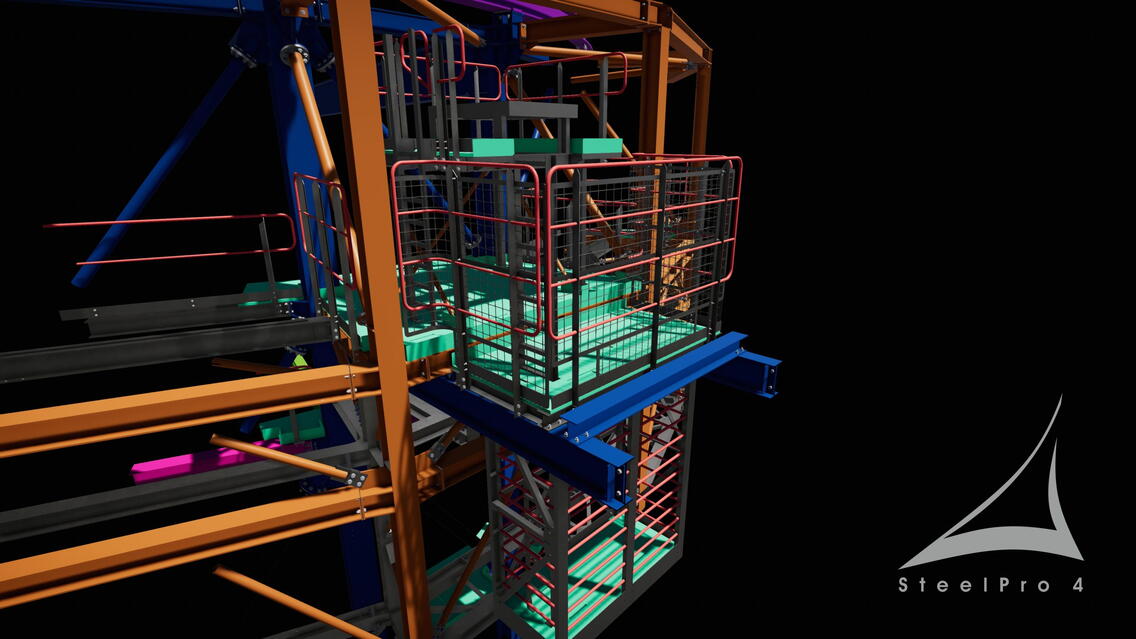

Because of the structure’s shape, a large amount of placed equipment and piping routes were necessary to communicate with the receiver’s main architect and also with the structural engineer’s office (Allcons Industry s.r.o.) about the design itself, but also to find the best solution for technology space requirements and its clashes with the structures.

The big advantage of the project was the opportunity to exchange 3D models with different professions and be able to check the progress of works, but also its continuity with each other. Also, because of the required delivery dates, it was used as an opportunity to split the structure into different production units, which were immediately released to the buyer and producer upon completion, who made his drawings for both the workshop and the site.

Another unique point of the project was the fact that because of the structural complexity, the 3D model was for all communication and data exchange preceded to standard drawings, which were issued later on.