Project description

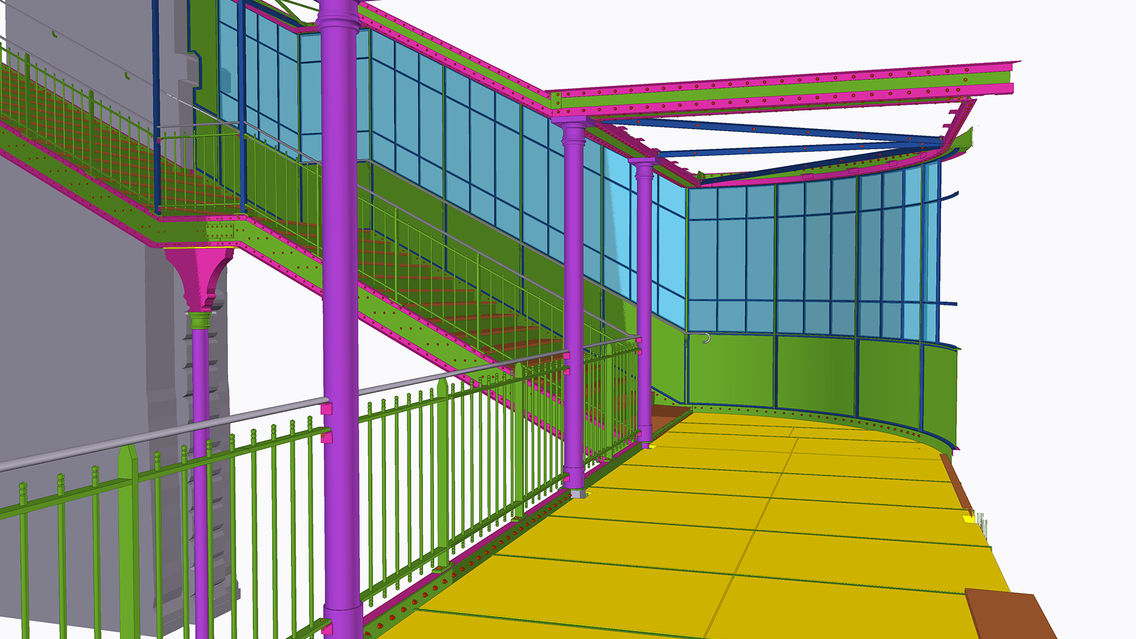

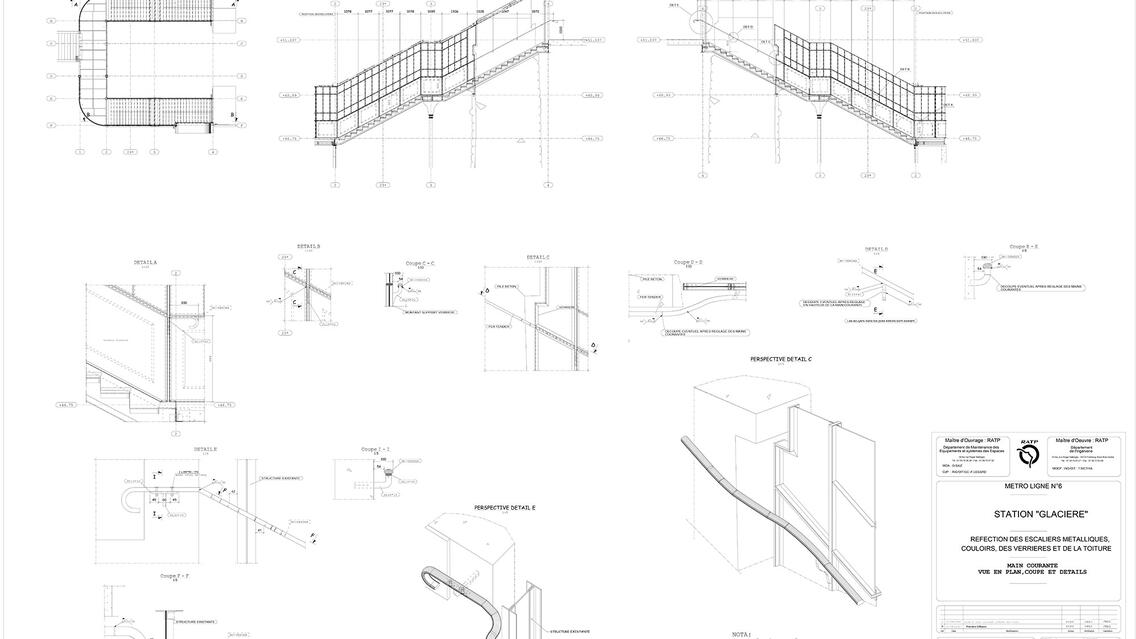

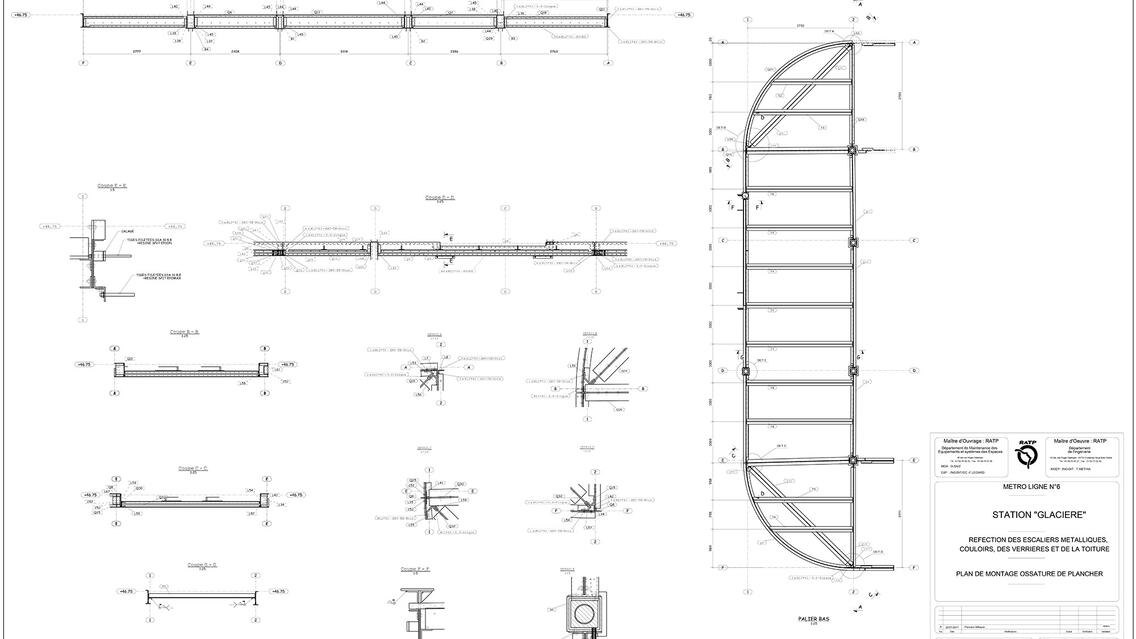

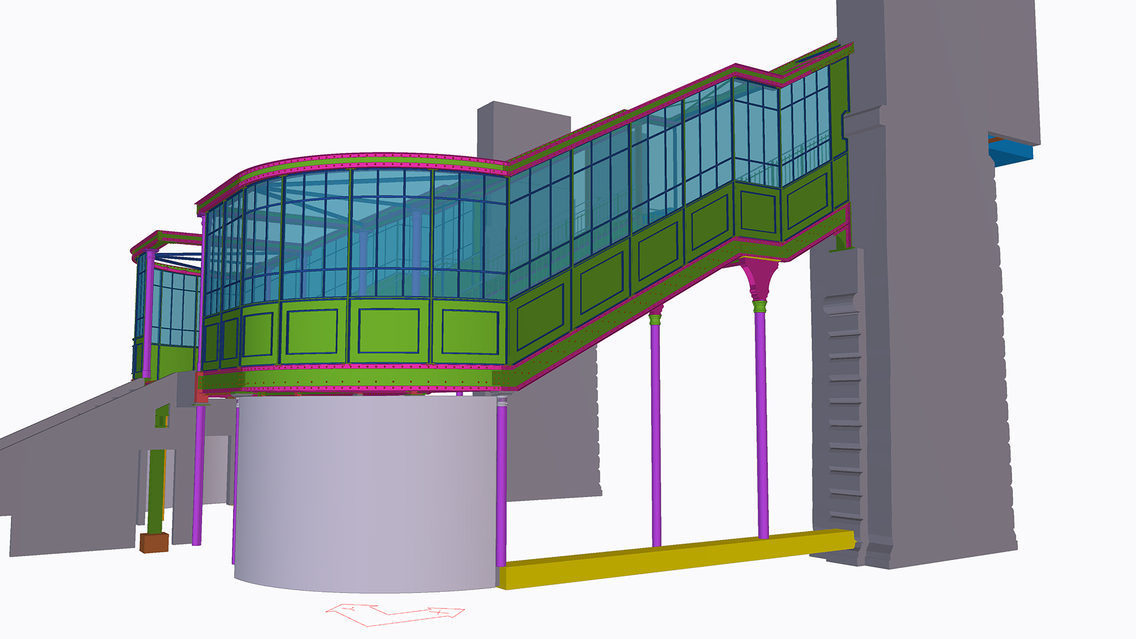

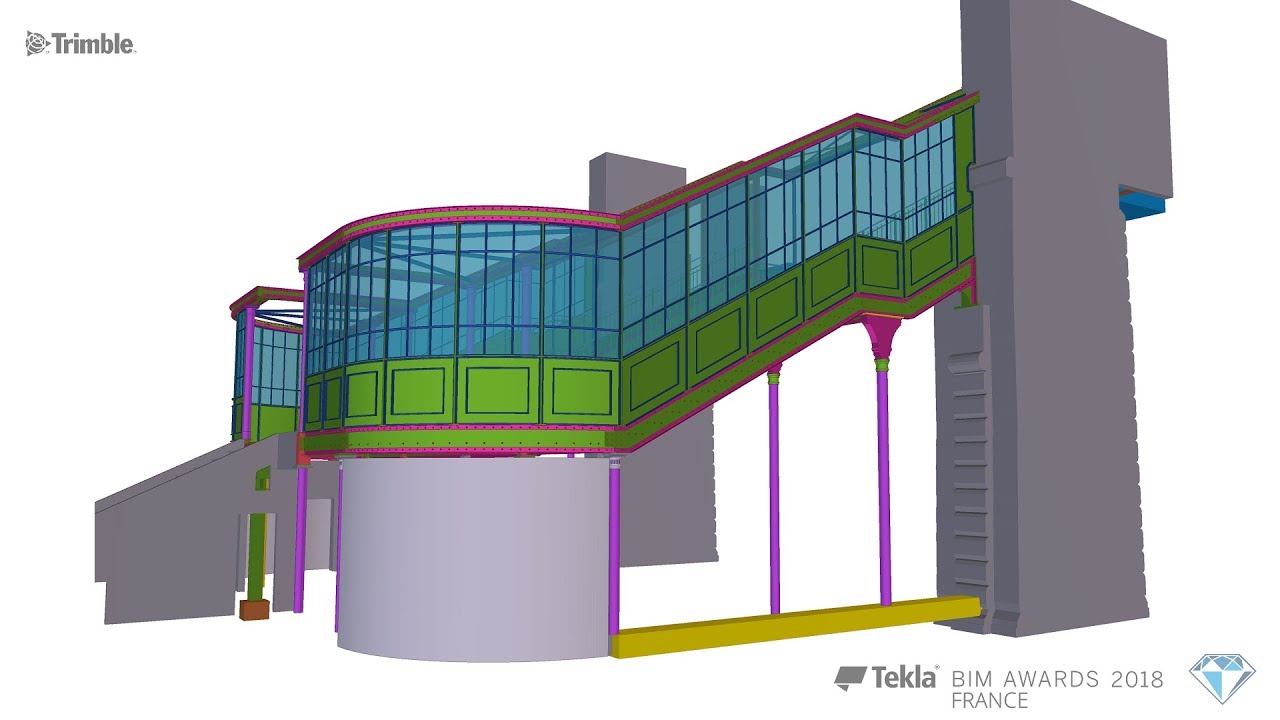

Metro station line No. 6. Identical reconstruction of the staircases giving access to the wharfs.

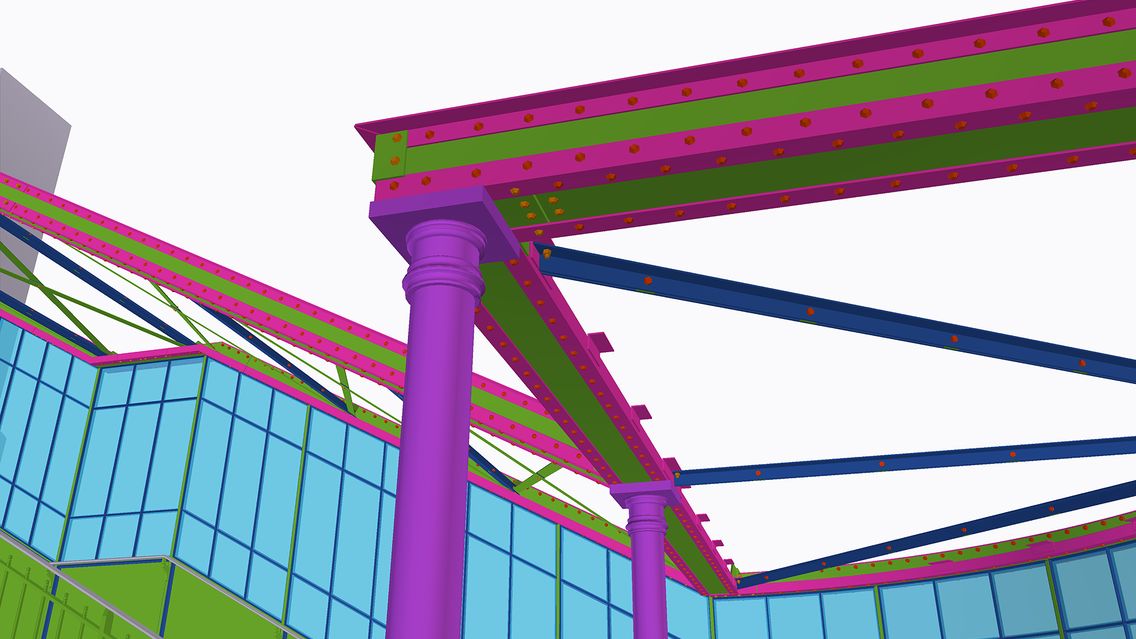

Eiffel-type building with riveted beams. Reconstruction according to Eurocodes and EN1090-2

Use of approximately 6,500 HRC domed head bolts and rivets (2,370 rivets and 4,130 HRC bolts)

What were the challenges encountered that contributed to the project's success?

Very short deadlines

- from the end of May to mid-July 2017: studies using the surveyor's statement.

- Modeling, plans, tracking / from the start of July to end of August 2017

- demolition of the existing structure, manufacture, assembly of the new structure, and opening to the public on August 28, 2017.

Complex structure

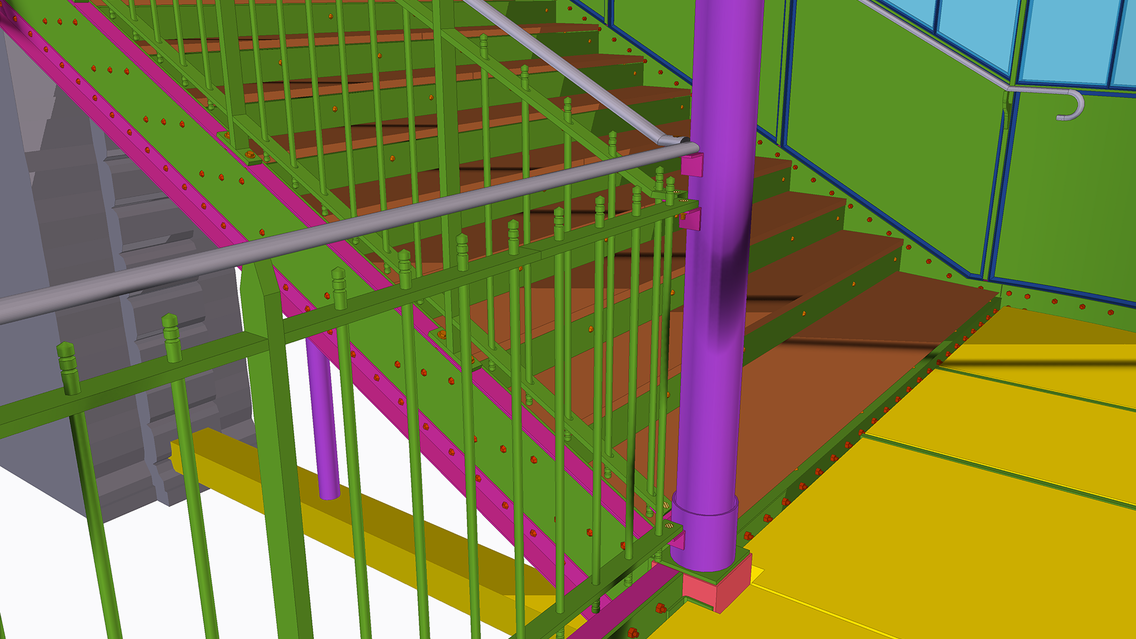

- identical reconstruction signifies a perfect visual between the old and new structure

- complex and clever details. Difficulty of justification in calculations: complex assembly nodes

- strict regulation on the stairs and guard rails to be adhered to: precision of the step height to the millimeter, while the existing environment had imperfections of several centimeters.

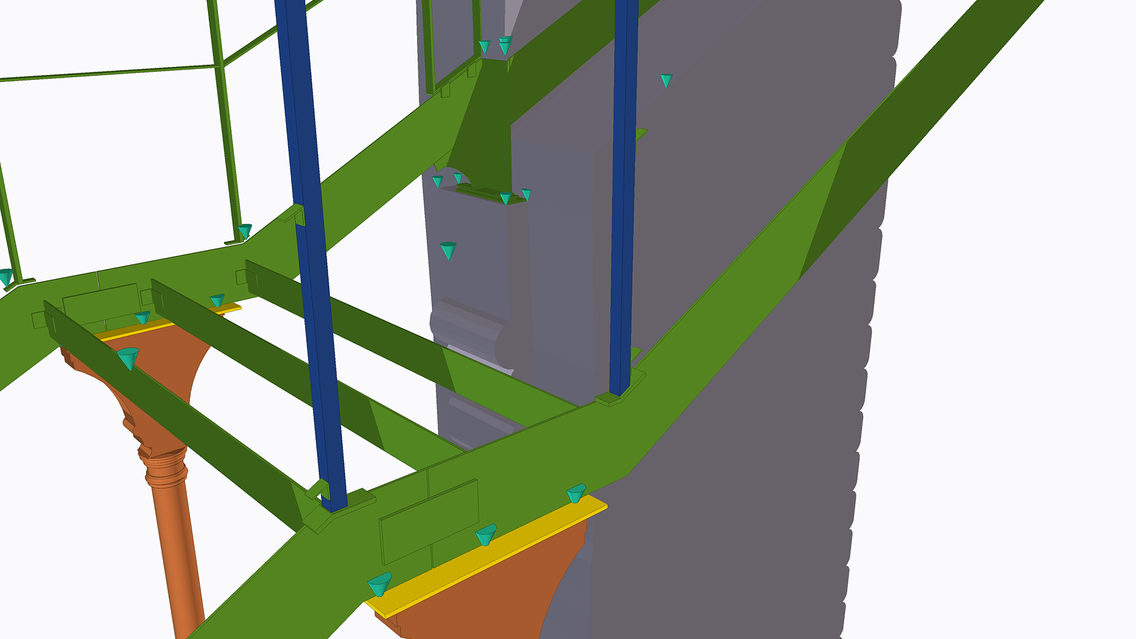

Adjustment in relation to the existing structure

- Model including all of the principal plots: existing environment, metal structure, concrete flooring in prefabricated slabs (to gain work time), steps, locksmithing, skylights, windows, etc.

What benefits did BIM and Tekla Structures provide to you?

Modeling the existing structure

- Using the 3D surveyor's statement, the use of the Trimble RealWorks Viewer software to determine the coordinates of the existing structure. Importation of the reference points from the existing structure into the Tekla model (gain of time/exact installation of the existing structure).

Modeling the new structure with Tekla Structures version 2016

- metal structure (right and curved portions)

- cast-iron columns

- steps

- guard rails

- hand rails (profile imported from an Autocad file)

- skylights and layout of glazed/unglazed pans

- prefabricated concrete slabs and reinforcement modeling;

- concrete and wood reinforcements of the existing structure.

Using Tekla Structures, creation of 3D plans and outflow in IFC and PDF-3D for viewing on Tekla BIMSight, Adobe Reader, and other 3D viewers for validation. Due to the short deadlines, several manufacturing sites worked based on the plots. Thanks to Tekla Structures, we broke down the project into several slices based on the planning and manufacturing sites. Tracking (flows and assemblies) and reinforcements were done on Tekla Structures. The assembly plans (work shop assembly and work site assembly) were done on Tekla Structures.